Method for preparing single crystal silver nano-wire by plant biomass reduction

A technology for plant biomass and silver nanowires, which is applied in the field of preparing single crystal silver nanowires by reducing plant biomass, can solve the problems of high reduction temperature, high preparation cost, high price, etc., and achieves mild reaction conditions and good dispersibility. , the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

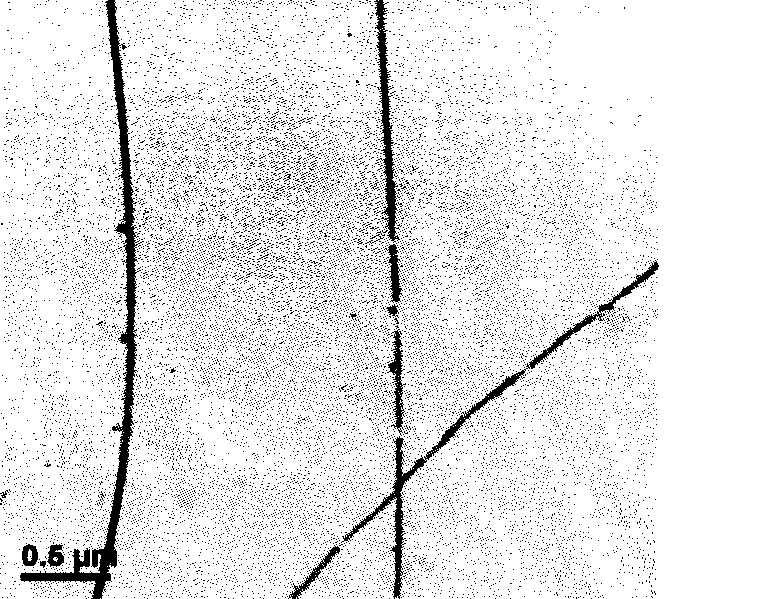

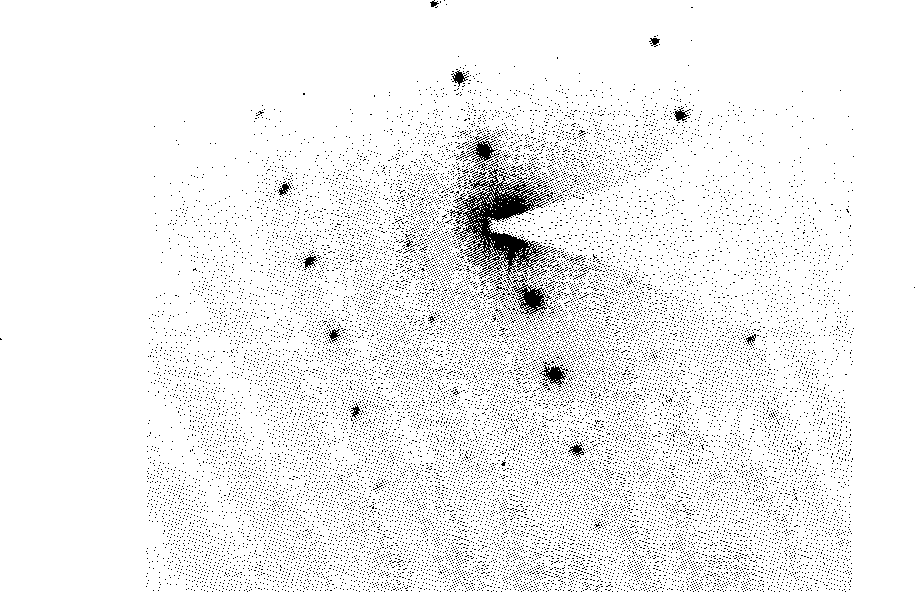

[0019] Accurately weigh 2.0 g of ground sausage leaf dry powder, add 50 mL of distilled water to boil, keep for 5 min, and filter the boiling liquid after cooling to room temperature, and dilute the filtrate to 50 mL with distilled water to obtain a sausage leaf extract with a concentration of 40 g / L; Mix 25mL of this extract with 25mL of silver nitrate solution with a molar concentration of 2mmol / L, place in a constant temperature water-bath shaker (30°C, 150rpm) and shake for 24h to obtain silver particles with a length of 0.5-15μm and an average diameter of 52.7nm. Nanowires. figure 1 Provide the TEM picture of the silver nanowire prepared by the present embodiment, from figure 1 It can be seen that there is formation of silver nanowires. figure 2 Give the SAED picture of the silver nanowire that present embodiment prepares, from figure 2 It can be seen that the diffraction patterns are regularly arranged spots, which proves that the obtained silver nanowires are single...

Embodiment 2

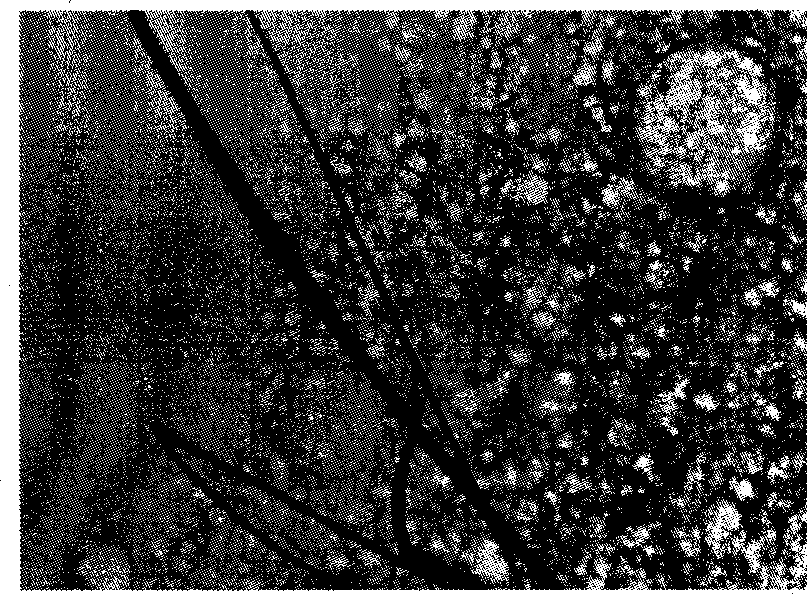

[0021] Accurately weigh 2.0 g of ground sausage leaf dry powder, add 50 mL of distilled water to boil, keep for 5 min, and filter the boiling liquid after cooling to room temperature, and dilute the filtrate to 50 mL with distilled water to obtain a sausage leaf extract with a concentration of 40 g / L; Mix 50mL of this extract with 50mL of silver nitrate solution with a molar concentration of 2mmol / L, place in a constant temperature water-bath shaker (30°C, 150rpm) and shake for 48h to obtain silver particles with a length of 0.5-30μm and an average diameter of 85.4nm. Nanowires. image 3 The TEM picture of the silver nanowire prepared for this embodiment, from image 3 The formation of many silver nanowires can be seen in .

Embodiment 3

[0023] Accurately weigh 2.0 g of ground sausage leaf dry powder, add 50 mL of distilled water to boil, keep for 5 min, and filter the boiling liquid after cooling to room temperature, and dilute the filtrate to 50 mL with distilled water to obtain a sausage leaf extract with a concentration of 40 g / L; Mix 25mL of this extract with 25mL of silver nitrate solution with a molar concentration of 3mmol / L, place in a constant temperature water bath shaker (30°C, 150rpm) and shake for 52h to obtain silver particles with a length of 0.3-60μm and an average diameter of 67.6nm. Nanowires. Figure 4 The TEM picture of the silver nanowire prepared for this embodiment, from Figure 4 The formation of a large number of silver nanowires can be seen in .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com