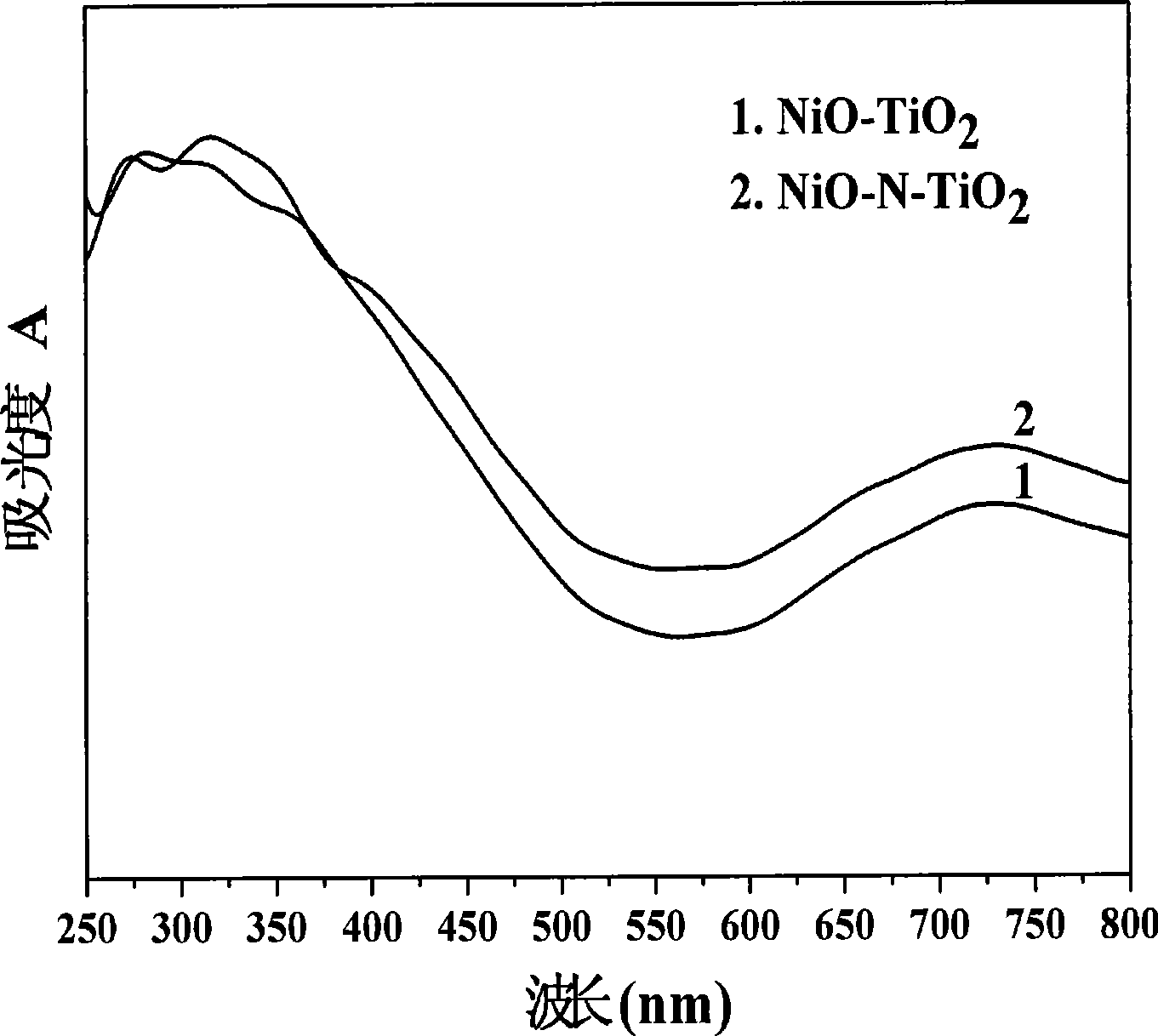

Inorganic sensitized visible-light responsive photocatalyst and preparation method thereof

A photocatalyst and visible light technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of less than 5% utilization rate of light energy, low utilization rate of light energy, etc. The effect of stable visible light activity, low cost and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] a. Add 0.005mol of nickel nitrate hexahydrate, 0.002mol of titanium tetrachloride and 0.1mol of urea into 100mL of deionized water, and stir until uniform;

[0020] b. Transfer solution a into a 250mL three-necked flask, and react for 10h under stirring and reflux conditions;

[0021] c. After the reaction, the product is suction filtered, washed with deionized water to pH 7, and the filter cake is dried in an oven at 60°C to obtain precursor powder.

[0022] d. Put the precursor powder into a porcelain crucible, heat it in a muffle furnace from room temperature to 500°C, keep it for 4 hours, and naturally drop to room temperature to obtain nickel oxide sensitized nitrogen-doped titanium dioxide photocatalyst (NiO-N-TiO 2 ).

Embodiment 2

[0024] a. Add 0.005mol of nickel nitrate hexahydrate, 0.002mol of titanium tetrachloride and 0.1mol of urea into 100mL of deionized water, and stir until uniform;

[0025] b. Transfer solution a to a 250mL three-necked flask, and react for 2h under stirring and reflux conditions;

[0026] c. After the reaction is over, the product is suction filtered and washed with deionized water to pH 8;

[0027] d. Stir the filter cake with 100mL 0.008mol sodium carbonate to form a suspension;

[0028] e. Transfer the above suspension to a 200mL high temperature and high pressure hydrothermal kettle, and place it in a 100°C oven for 10 hours;

[0029] f. After the reaction, the product is suction filtered, washed with deionized water to pH 7, and the filter cake is dried in an oven at 60°C to obtain precursor powder.

[0030] g. Put the precursor powder into a porcelain crucible, heat it in a muffle furnace from room temperature to 500°C, keep it for 4 hours, and naturally cool to room tempera...

Embodiment 3

[0032] a. Add 0.0025mol nickel nitrate hexahydrate, 0.0025mol zinc nitrate hexahydrate, 0.002mol titanium tetrachloride and 0.1mol urea into 100mL deionized water and stir until uniform;

[0033] b. Transfer solution a into a 250mL three-necked flask, and react for 10h under stirring and reflux conditions;

[0034] c. After the reaction, the product is suction filtered, washed with deionized water to pH 7, and the filter cake is dried in an oven at 60°C to obtain precursor powder.

[0035] d. Put the precursor powder into a porcelain crucible, heat it in a muffle furnace from room temperature to 500°C, keep it for 4 hours, and naturally drop to room temperature to obtain nickel oxide-sensitized zinc oxide and nitrogen-doped titanium dioxide photocatalyst (NiO-ZnO and NiO-N-TiO 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com