Method for synthesizing cetyl diphenyl ether sodium disulfonate and use

A technology of cetyl diphenyl ether and sodium disulfonate, which is applied in the direction of sulfonate preparation, drilling compositions, chemical instruments and methods, etc., can solve the problems of poor biodegradability, low content of active substances, no Resistance to hard water and other issues, to achieve the effect of good product quality, high content of active substances, and excellent resistance to hard water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

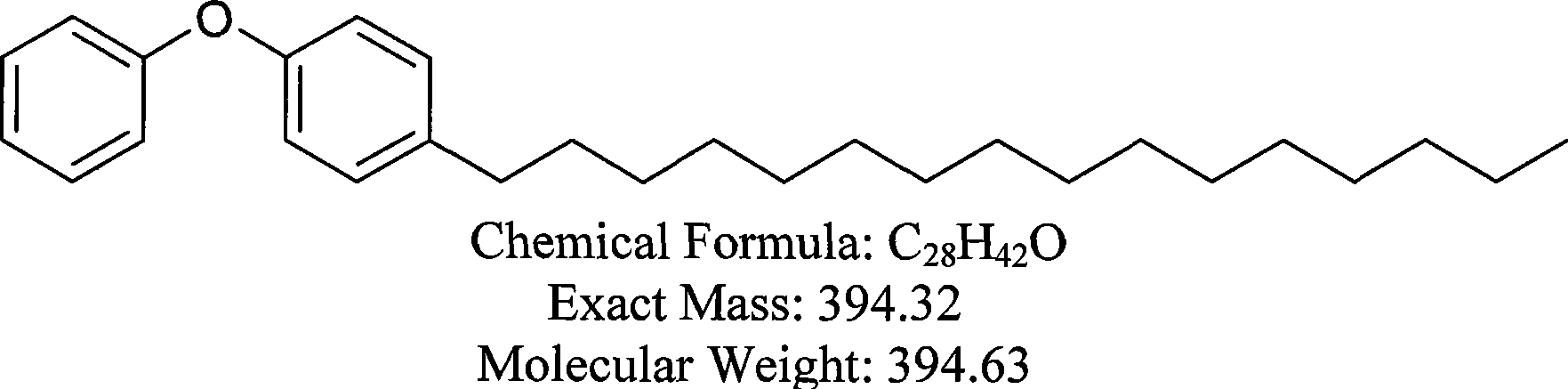

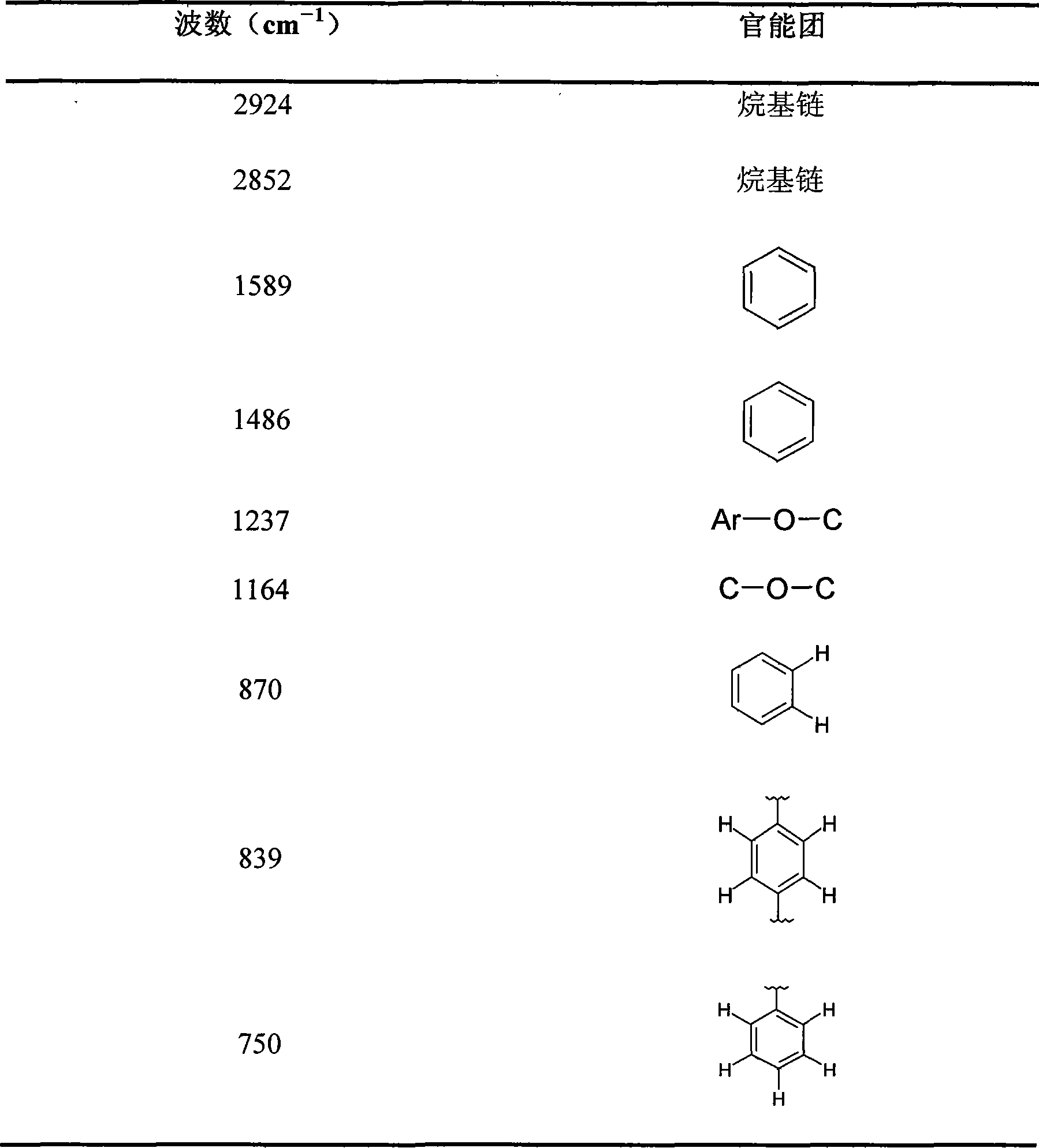

Image

Examples

Embodiment 1

[0015] Add diphenyl ether into a dry three-necked flask, add AlCl 3 Catalyst, heat and stir to dissolve it, and raise the temperature to 90°C; put hexadecene into a constant pressure dropping funnel, in which diphenyl ether: AlCl 3 : The molar ratio of hexadecene is 16:1.14:11.4, and it is added dropwise into the reaction flask within 0.5h, stirred, and the temperature is controlled. Constant temperature reaction 6.0h.

[0016] After the reaction was completed, an equal volume of deionized water, saturated Na 2 CO 3 solution, washed with deionized water, separated, discarded the aqueous layer, and washed with anhydrous Na 2 SO 4 The oil layer was dried, filtered, and distilled under reduced pressure at 400 Pa, so that all the raw materials were evaporated, and the product obtained by continuing distillation was the target product hexadecyl diphenyl ether, and the molar conversion rate was 51.8%.

[0017] Add cetyl diphenyl ether and 20ml of petroleum ether into a three-ne...

Embodiment 2

[0019] Add diphenyl ether into a dry three-necked flask, add AlCl 3 Catalyst, heat and stir to dissolve it, and raise the temperature to 90°C; put hexadecene into a constant pressure dropping funnel, in which diphenyl ether: AlCl 3 : The molar ratio of hexadecene is 16:2:10, and it is added dropwise into the reaction flask within 0.5h, stirred, and the temperature is controlled. Constant temperature reaction 6.0h.

[0020] After the reaction was completed, an equal volume of deionized water, saturated Na 2 CO 3 solution, washed with deionized water, separated, discarded the aqueous layer, and washed with anhydrous Na 2 SO 4 The oil layer was dried, filtered, and distilled under reduced pressure at 400 Pa until all the raw materials were evaporated, and the product obtained by continuing distillation was the target product hexadecyl diphenyl ether, and the molar conversion rate was 60.9%.

[0021] The molar ratio of hexadecyl diphenyl ether: oleum (50%) in Example 1 was ch...

Embodiment 3

[0023] Add diphenyl ether into a dry three-necked flask, add AlCl 3 Catalyst, heat and stir to dissolve it, and raise the temperature to 90°C; put hexadecene into a constant pressure dropping funnel, in which diphenyl ether: AlCl 3 : The molar ratio of hexadecene is 16:2.82:9.4, and it is added dropwise into the reaction flask within 0.5h, stirred, and the temperature is controlled. Constant temperature reaction 6.0h.

[0024] After the reaction was completed, an equal volume of deionized water, saturated Na 2 CO 3 solution, washed with deionized water, separated, discarded the aqueous layer, and washed with anhydrous Na 2 SO 4 The oil layer was dried, filtered, and distilled under reduced pressure at 400 Pa until all the raw materials were evaporated, and the product obtained by continuing distillation was the target product hexadecyl diphenyl ether, and the molar conversion rate was 60.7%.

[0025] The molar ratio of hexadecyl diphenyl ether: fuming sulfuric acid (50%) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com