Electric bi-stable device based on composite film of semi-conductor nano crystalline and polymer

A technology of bistable devices and composite films, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., and can solve the problem of low current switching of electric bistable devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

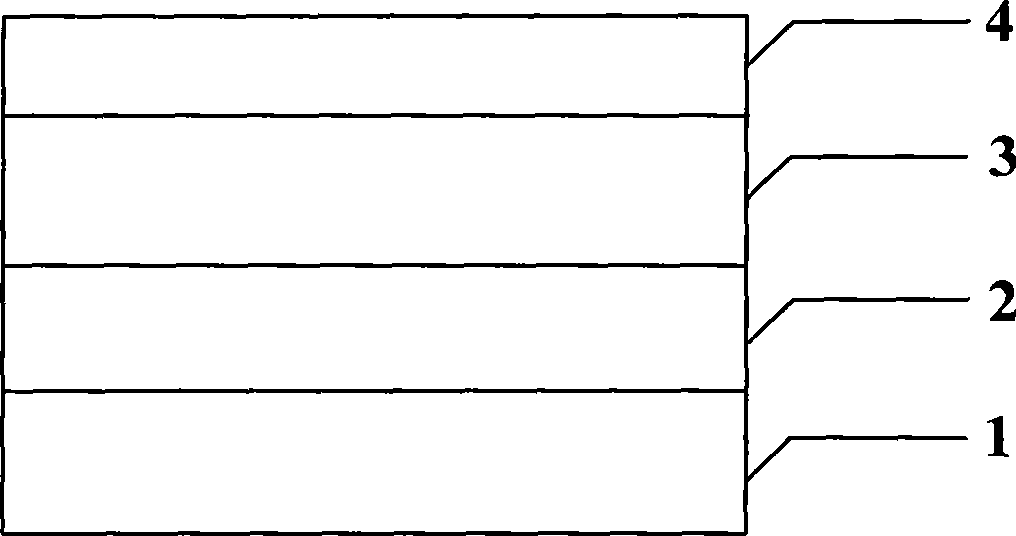

[0020] An electric bistable device based on a composite thin film of semiconductor nanocrystals and polymers. The device is made of indium tin oxide (ITO) conductive glass on a conductive substrate 1, and a buffer layer 2 is prepared by a spin-coating process. The spin-coated The speed is 5000 rpm. The functional active layer 3 above the buffer layer 2 is also prepared by a spin-coating process. This layer is made of cuprous sulfide nanocrystals and conjugated polymer poly(2-methoxy-5-(2) coated with dodecanethiol. -Ethylhexyloxy)-1,4-phenyleneethylene) mixed film, spin-coated at 1000 rpm. On top of the functional active layer 3 is a vacuum-evaporated aluminum electrode 4 .

[0021] Materials used in this example:

[0022] The material of the buffer layer 2 is sulfonated polystyrene-doped poly-3,4-ethylenedioxythiophene (PEDOT:PSS), and the thickness of the buffer layer 2 is 50 nm.

[0023] The material of the functional active layer 3 is cuprous sulfide nanocrystal coated ...

Embodiment 2

[0026] An electric bistable device based on a composite thin film of semiconductor nanocrystals and polymers. The device is made of indium tin oxide (ITO) conductive glass on a conductive substrate 1, and a buffer layer 2 is prepared by a spin-coating process. The spin-coated The speed is 5000 rpm. The functional active layer 3 above the buffer layer 2 is also prepared by a spin-coating process. This layer is made of cuprous sulfide nanocrystals and conjugated polymer poly(2-methoxy-5-(2) coated with dodecanethiol. -Ethylhexyloxy)-1,4-phenyleneethylene) mixed film, spin-coated at 1000 rpm. On top of the functional active layer 3 is a vacuum-evaporated aluminum electrode 4 .

[0027] Materials used in this example:

[0028] The material of the buffer layer 2 is poly-3,4-ethylenedioxythiophene doped with sulfonated polystyrene, and the thickness of the buffer layer 2 is 100 nm.

[0029] The material of the functional active layer 3 is cuprous sulfide nanocrystal coated with 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com