Method for preparing rod-shaped hydroxyapatite capable of controlling nano size

A rod-shaped hydroxyapatite, nano-sized technology, applied in medical science, prosthesis, etc., can solve the problems of difficult control of nano-scale crystal structure, poor mechanical properties and biocompatibility, and uncontrollable morphology. Achieve the effects of improving mechanical properties and biocompatibility, regular shape, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Slowly add 0.24g 80wt% H3PO4 solution in 20ml concentration of 2wt% chitosan quaternary ammonium salt solution, add dropwise 5mol / l NaOH solution to pH=9 under magnetic stirring, then add 10ml 0.225mol / l CaCl2 dropwise Solution, during which the pH of the system was maintained at 9. After the dropwise addition was completed, the stirring reaction was continued for 0.5h. Then the solution in the reaction system was transferred to a 50ml polytetrafluoroethylene steel autoclave, and reacted at 90°C for 20h. Suction filtration, washing, and drying at 45°C.

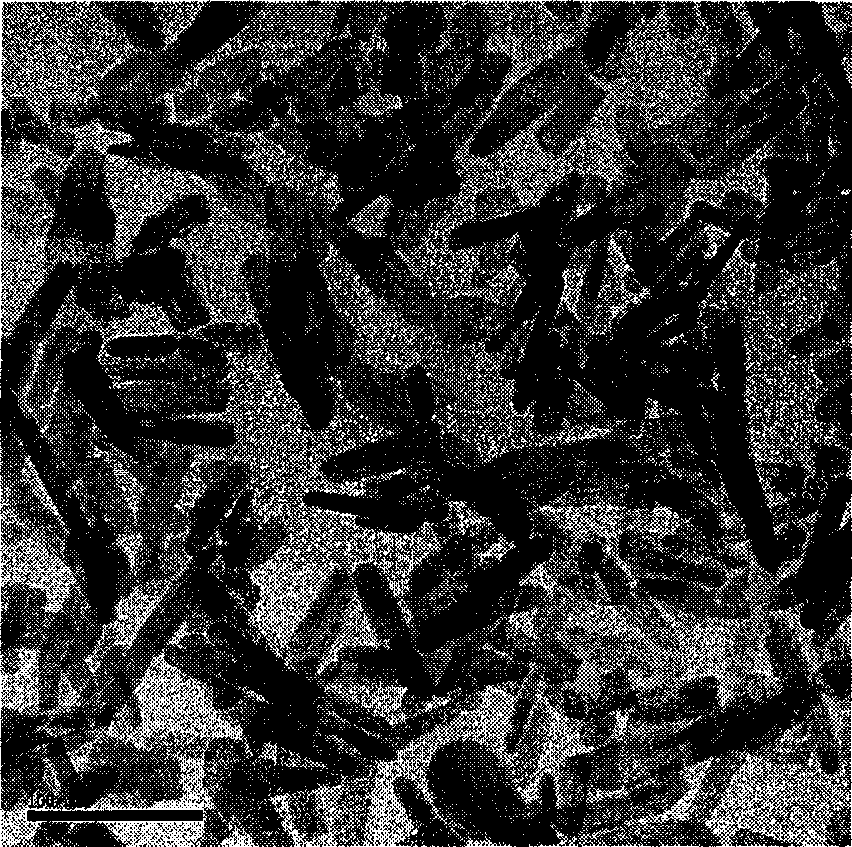

[0033] Such as image 3 Shown:

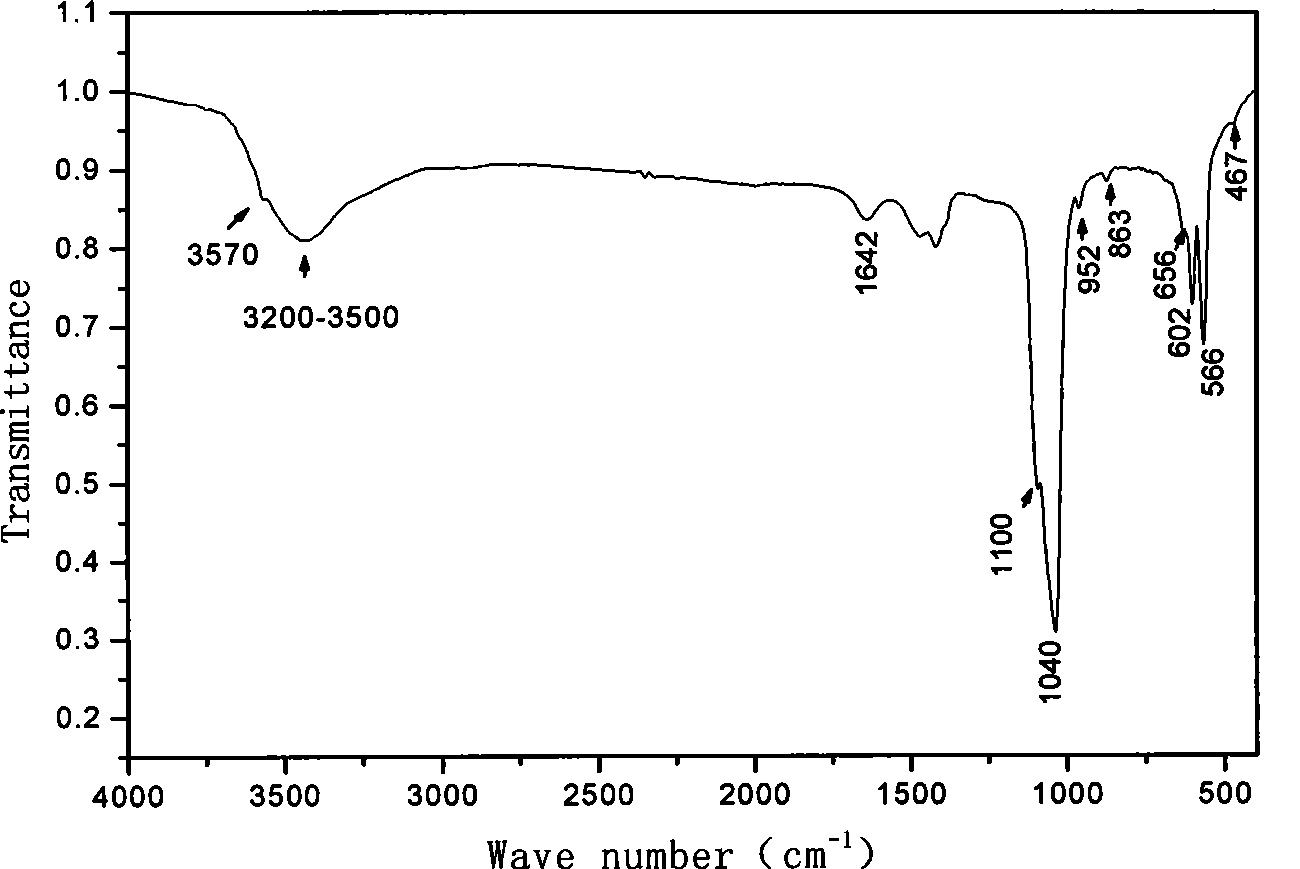

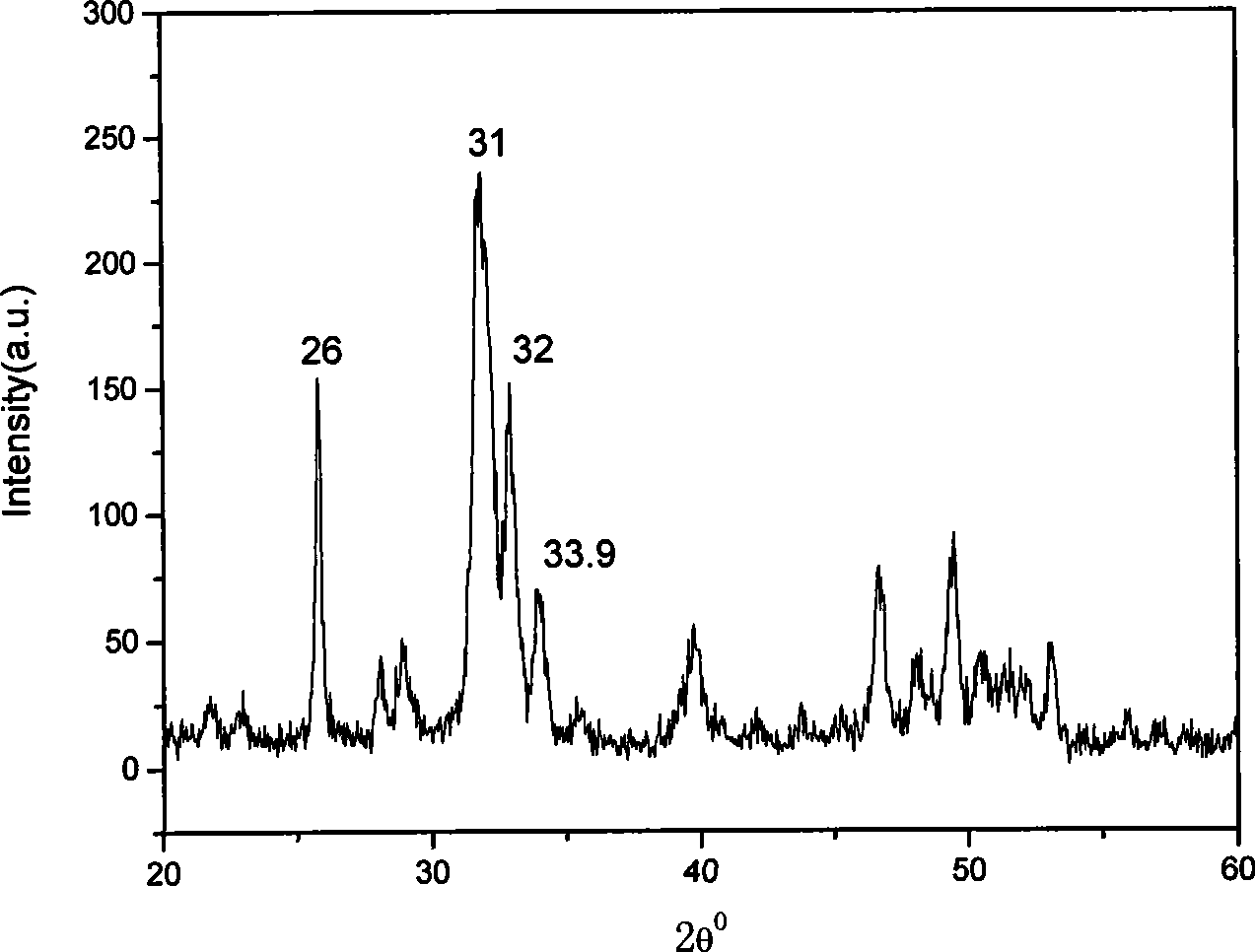

[0034] Infrared spectrum and X-ray diffraction technical characterization results show that the preparation of the present invention is clean, crystalline and rod-shaped hydroxyapatite. Dimensions and aspect ratio see Figure 7 shown.

Embodiment 2

[0036] The preparation method is the same as that of Example 1, as long as the hydrothermal temperature is changed from 90°C to 120°C.

[0037] Such as Figure 4 Shown:

[0038] Morphology of hydroxyapatite. Dimensions and aspect ratio see Figure 7 shown.

Embodiment 3

[0040] The preparation method is the same as that of Example 1, except that the hydrothermal temperature is changed from 90°C to 150°C.

[0041] Such as Figure 5 Shown:

[0042] Morphology of hydroxyapatite. See size and aspect ratio Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com