Eutrophication water body artificial wetland processing system taking steel-making waste residue as a substrate

A technology of artificial wetland and eutrophication, applied in the field of water treatment, can solve the problems of effluent pH rise and retention, etc., and achieve the effects of enhancing impact resistance, reducing land area, and good stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

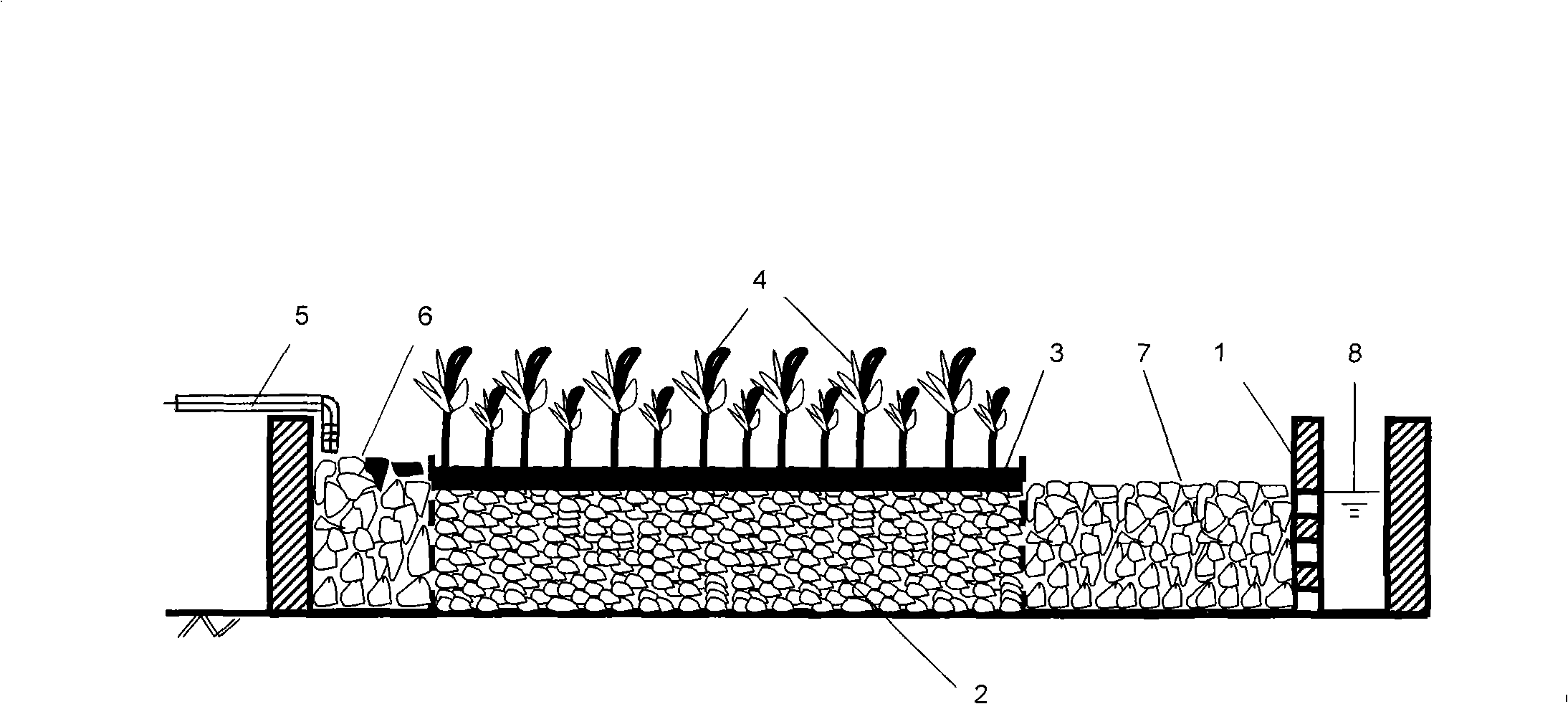

[0023] The test device consists of two sets of horizontal subsurface flow wetland systems A and B, and the artificial wetland pool body 1 is welded by PVC plastic plates. Constructed wetland pool body 1 has a volume of 0.64m 3 (2.0m×0.4m×0.8m), each end has a gravel water distribution area 5 and a gravel outlet area 7 with a length of 15cm and 25cm respectively, and 9 sampling ports are arranged on the side of the device. The matrix layer 2 is made of mixed steel slag and dry slag with a particle size of 5-15 mm, the volume ratio of steel slag and dry slag is 4:1, and the filling thickness is 55 cm. The upper layer is covered with crushed stones of 5-8 mm as the covering layer 3 . Constructed wetland system A planted a single wetland plant Typha angustifolia as wetland plant system 4; constructed wetland system B adopted the mixed planting mode of typha (Typha angustifolia) and windmill grass (Cyperous alternifolius) as wetland plant system 4. The planting density of the two...

Embodiment 2

[0026] Experimental site: Water environment restoration experimental base in Qianwei Village, a certain county.

[0027] Treatment object: Qianwei village landscape water body (central lake). Due to the rapid development of local farmhouse tourism and the absence of sewage treatment facilities, a large amount of domestic sewage is directly discharged into the water body without treatment, resulting in a heavy nutrition state in the central lake. In particular, the content of organic matter and total phosphorus in the water body is relatively high.

[0028] Construction of the constructed wetland treatment system: The constructed wetland pool body 1 is transformed from an abandoned greenhouse fish pond (brick-concrete structure). The length and width of the constructed wetland pool body 1 are 50m×8.5m respectively. The horizontal subsurface flow constructed wetlands (HFs) were used to construct the model. The steel slag and dry slag with a particle size of 5-15 mm are soaked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com