Environmental friendly synthetic detergent taking poly epoxy succinic acid as washing assistant

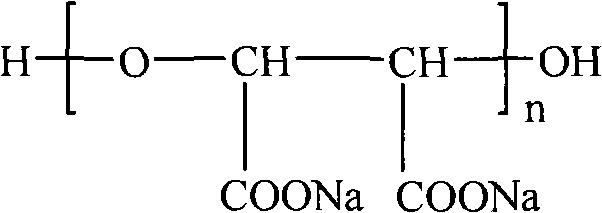

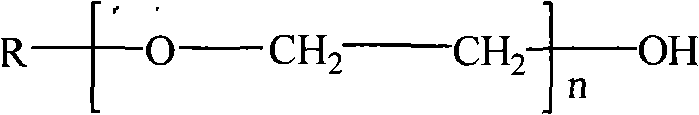

A technology of polyepoxysuccinic acid and synthetic detergent, applied in detergent compounding agent, detergent composition, organic detergent composition and other directions, can solve the problems of high phosphorus content, eutrophication of water body, etc., and achieve strong redeposition , The effect of reducing the amount of use and preventing redeposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Preparation of synthetic detergent: preparation of environmentally friendly synthetic detergent 100.00g

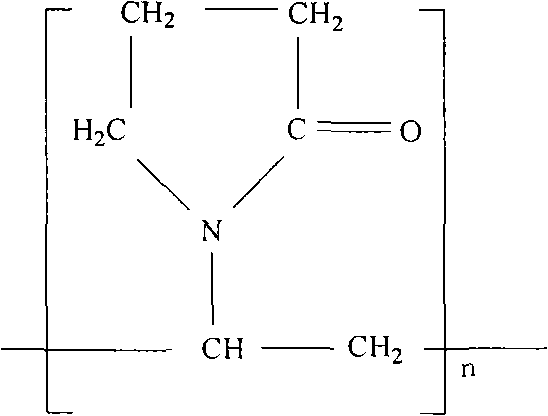

[0050] First, the liquid preparation 7.14g of fatty alcohol polyoxyethylene ether sodium sulfate with a solid content of 70%, 50.00g of polyepoxysuccinic acid with a solid content of 40%, and 37.50g of a linear alkyl benzene sulfonic acid with a solid content of 40% After the sodium is evenly mixed, place it in a dryer and bake at 105°C for 2 hours. After taking it out, add 1.00g polyvinylpyrrolidone, 5.00g sodium bicarbonate, 5.00g borax, 10.00g sodium silicate, 0.20g fluorescence enhancement. The whitening agent VBL is supplemented with sodium sulfate to a weight of 100.00g to obtain an environment-friendly synthetic detergent 100.00g.

[0051] The experimental results are shown in Table 1.

Embodiment 2

[0053] Preparation of synthetic detergent: preparation of environmentally friendly synthetic detergent 100.00g

[0054] First, the liquid preparation 10.00g of fatty alcohol polyoxyethylene ether sodium sulfate with a solid content of 70%, 50.00g of polyepoxysuccinic acid with a solid content of 40% and 37.50g of a linear alkyl benzene sulfonic acid with a solid content of 40% After the sodium is evenly mixed, place it in a dryer and bake at 105°C for 2 hours. After taking it out, add 1.00g polyvinylpyrrolidone, 5.00g sodium bicarbonate, 5.00g borax, 10.00g sodium silicate, 0.20g fluorescence enhancement. The whitening agent VBL is supplemented with sodium sulfate to a weight of 100.00g to obtain an environment-friendly synthetic detergent 100.00g.

[0055] The experimental results are shown in Table 1.

Embodiment 3

[0057] Preparation of synthetic detergent: preparation of environmentally friendly synthetic detergent 100.00g

[0058] First, the liquid preparation 12.86g of fatty alcohol polyoxyethylene ether sodium sulfate with a solid content of 70%, 50.00g of polyepoxysuccinic acid with a solid content of 40%, and 37.50g of a linear alkyl benzene sulfonic acid with a solid content of 40% After the sodium is evenly mixed, place it in a dryer and bake at 105°C for 2 hours. After taking it out, add 1.00g polyvinylpyrrolidone, 5.00g sodium bicarbonate, 5.00g borax, 10.00g sodium silicate, 0.20g fluorescence enhancement. The whitening agent VBL is supplemented with sodium sulfate to a weight of 100.00g to obtain an environment-friendly synthetic detergent 100.00g.

[0059] The experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com