Method for separating tin and stibium from tin-lead anode slime

A technology of anode slime and tin-lead, which is applied in the field of antimony and tin separation, can solve problems such as poor operating environment, high acid consumption, and large acid mist, and achieve the effects of high added value, production cost saving, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

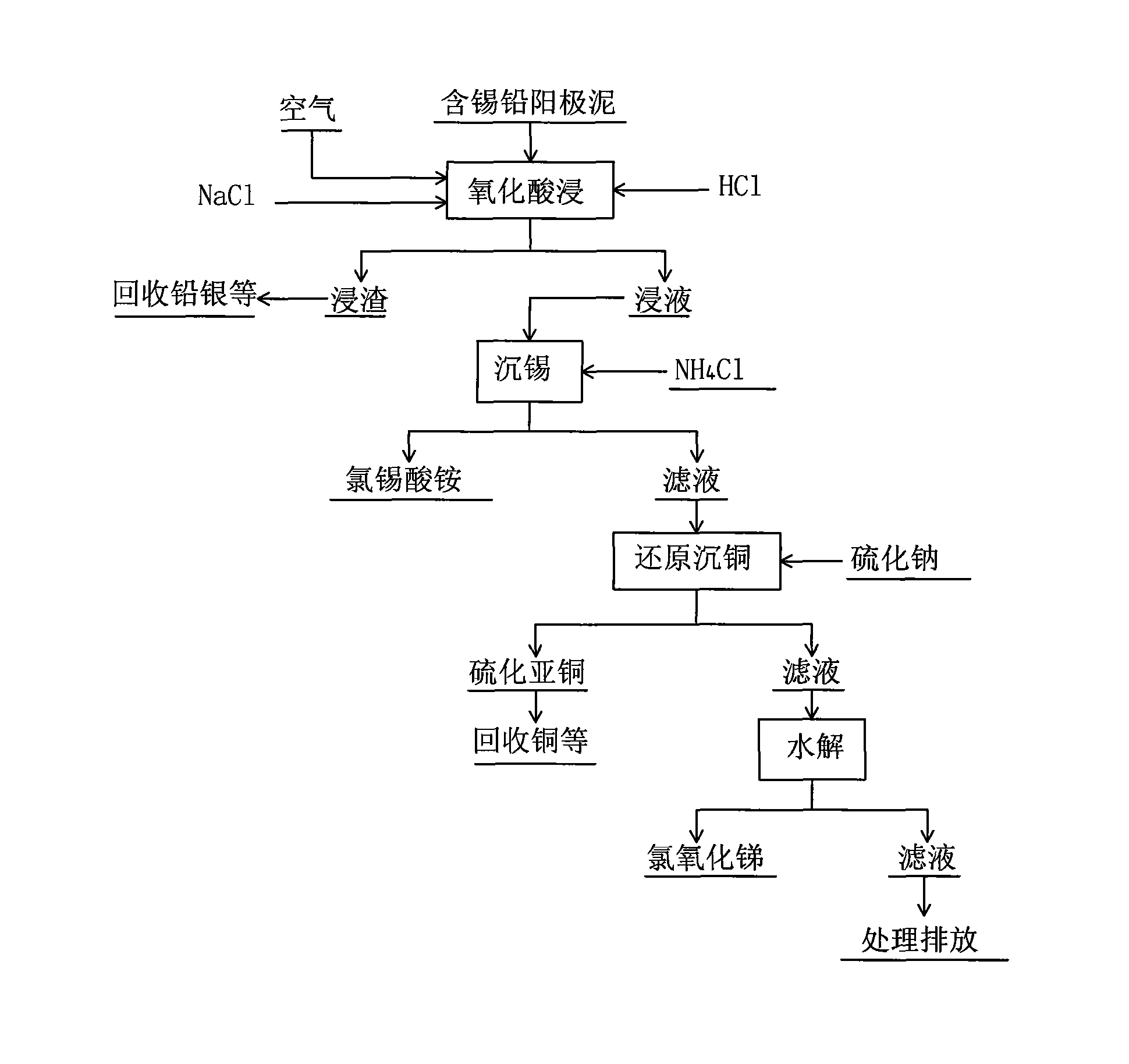

[0008] The attached drawing shows a method for separating tin and antimony from tin-lead anode slime. First, tin-lead anode slime is oxidized and acid-leached with hydrochloric acid and sodium chloride to make most of tin, antimony, bismuth, copper, etc. Into the acid leaching solution, it is separated from lead, silver, etc., and then tin in the acid leaching solution is selectively precipitated in the form of ammonium chlorostannate with ammonium chloride, so as to realize the separation of tin from antimony, bismuth, and copper; The filtrate is copper-immersed with sodium sulfide, and the copper-immersed liquid is hydrolyzed to obtain crude antimony oxychloride. The separation of tin and antimony is completed, and the hydrolyzed liquid is discharged after treatment. The specific process conditions are as follows:

[0009] 1. Oxidative acid leaching

[0010] Use hydrochloric acid and sodium chloride to leach the tin-lead anode slime material. Most of the main components of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com