Medium temperature solid oxide fuel cell composite cathode material and preparation method thereof

A solid oxide, composite cathode technology, applied in solid electrolyte fuel cells, battery electrodes, circuits, etc., can solve the problems of sintering temperature difference, high porosity of composite cathode, composite cathode and electrolyte, etc., achieve good sintering activity, solve the problem of cathode The effect of insufficient porosity and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

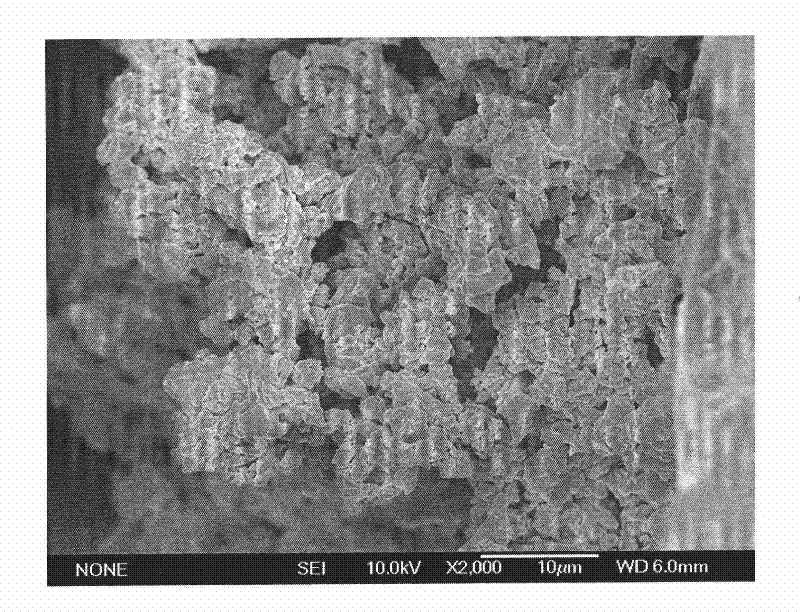

[0029] Example 1: Preparation of composite cathode ESB-LBSM for intermediate temperature solid oxide fuel cell by impregnation method

[0030] (1) The oxygen ion conductive material ESB (Bi 0.7 Er 0.3 o 1.5 ) powder: take 18.64g of Bi according to the stoichiometric ratio 2 o 3 and 6.5575 g of Er 2 o 3 , and then use zirconia balls as the ball milling medium and ethanol as the solvent to mix and ball mill for 3 hours with a planetary ball mill; the uniformly mixed Bi 2 o 3 and Er 2 o 3 The mixed powder was dried at 80 °C and then treated at 700 °C for 8 h to obtain cubic phase ESB (Bi 0.7 Er 0.3 o 1.5 ) powder, and then the obtained ESB powder was planetary ball milled for 3 hours according to the above method of mixing ball milling and dried at 80° C. to obtain dry ESB powder.

[0031](2) Preparation of ESB slurry: Mix 1g of ESB powder with 0.2g of soluble starch, add 30g of zirconia balls, mill on a planetary ball mill for 3 hours, take out and dry at 80°C, add 1...

Embodiment 2

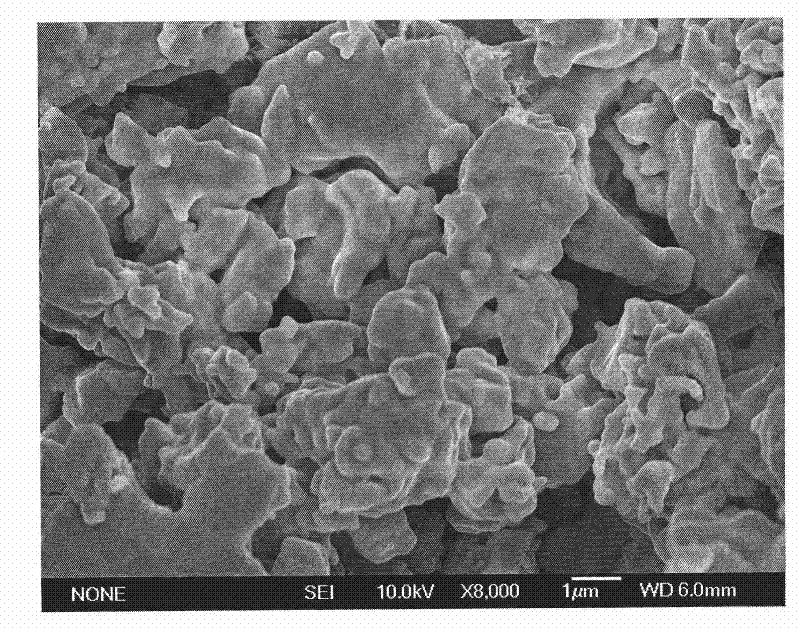

[0039] Example 2: Preparation of intermediate temperature solid oxide fuel cell composite cathode LBSM-ESB by impregnation method

[0040] (1) Preparation of cathode material LBSM by citric acid-nitrate reaction method ((La 0.74 Bi 0.10 Sr 0.16 )MnO 3-δ ) powder: according to the stoichiometric ratio, four kinds of nitrates containing La, Bi, Sr, and Mn elements were weighed and dissolved in dilute nitric acid solution, stirred at 60°C for 2 hours to form a clear solution, and a certain amount of Citric acid (citric acid moles: metal ion moles=1.25:1) was stirred at 80°C for 4 hours to obtain a sol, and the sol was dried at 120°C for 24 hours to obtain a xerogel, and the xerogel was heat-treated at 850°C for 5 hours, After cooling, grind to obtain LBSM cathode material powder.

[0041] (2) Preparation of LBSM slurry: Mix 1 g of LBSM powder with 0.25 g of soluble starch, add 30 g of zirconia balls, mill it on a planetary ball mill for 3 hours, take it out and dry it at 80°C...

Embodiment 3

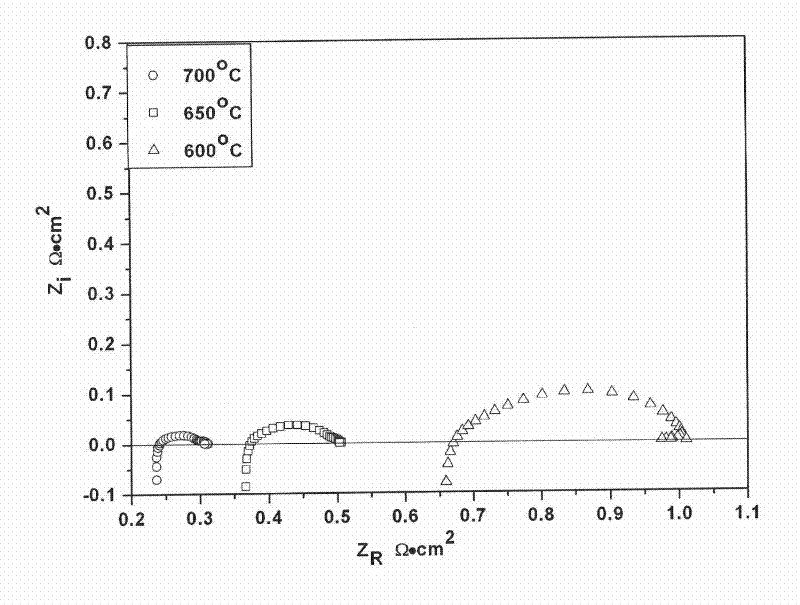

[0050] When A' is La, Ba or Y, preparation method is identical with embodiment 1 or 2. The mass percentage of LBSM cathode material in the whole composite cathode is 35-55%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com