Method for synthesizing titanium-silicon materials with mesoporous and microporous structures

A microporous structure, titanium-silicon technology, applied in chemical instruments and methods, crystalline aluminosilicate zeolites, molecular sieves and alkali exchange compounds, etc., can solve the environmental and cost burdens, the complicated preparation method steps, and the single size of the pores of the composite material. and other problems, to achieve the effect of reducing cost and environmental burden, eliminating local concentration unevenness, and improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

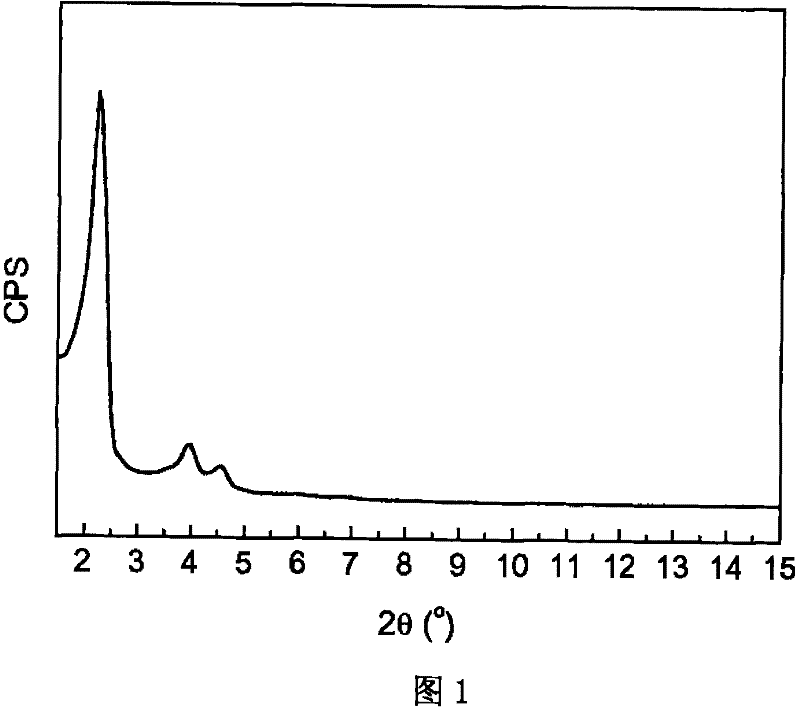

[0044] First, 30 grams of tetraethyl orthosilicate and appropriate amount of tetrabutyl titanate were added to the aqueous solution of tetrapropylammonium hydroxide respectively, and ultrasonically stirred at normal pressure and 40°C to mix them uniformly to form two kinds of solutions. After mixing the two solutions, add them to the aqueous solution of cetyltrimethylammonium bromide and continue ultrasonic stirring to make them evenly mixed. Among them, tetraethyl orthosilicate, tetrabutyl titanate, tetrapropylammonium hydroxide, The molar ratio of hexaalkyltrimethylammonium bromide to water is 1:0.02:0.4:0.05:25; the above system is transferred to a stainless steel sealed reaction kettle, and crystallized at a temperature of 100°C and autogenous pressure for 5 hours , and then crystallized at a temperature of 140°C and autogenous pressure for 48 hours, filtered the obtained crystallized product, washed with water, dried at 110°C for 120 minutes, and then calcined at a tempera...

Embodiment 2

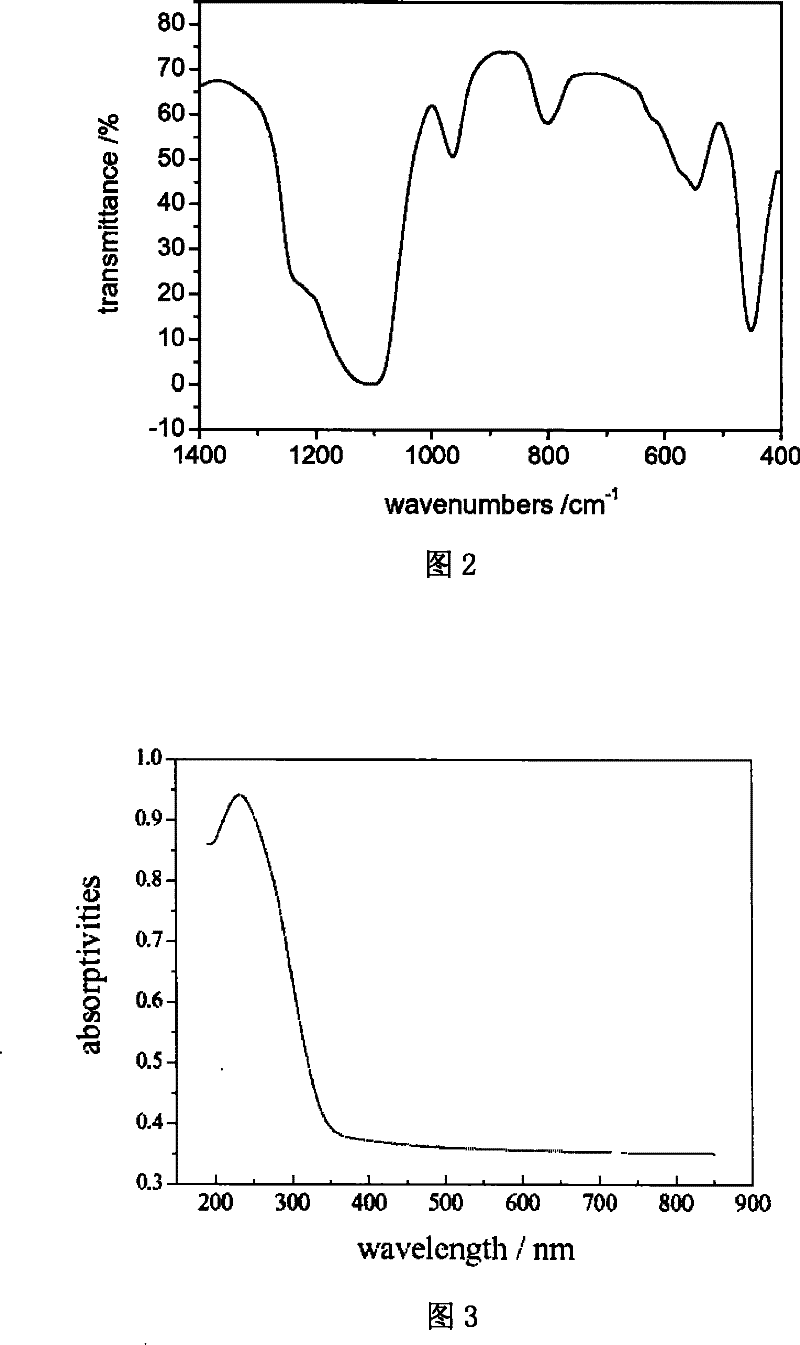

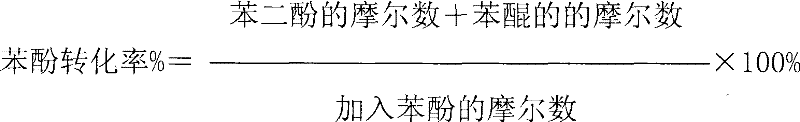

[0050] First, add 30 grams of tetraethyl orthosilicate and appropriate amount of tetrapropyl titanate to the aqueous solution of diethanolamine respectively, and stir them ultrasonically at normal pressure and 60°C to form two kinds of solutions, and mix the above two kinds of solutions Then add it to the aqueous solution of cetyltrimethylammonium bromide and continue ultrasonic stirring to make it evenly mixed, in which tetraethyl orthosilicate, tetrapropyl titanate, diethanolamine, cetyltrimethyl The molar ratio of ammonium to water is 1:0.08:0.2:0.2:180. Put this mixed solution into a stainless steel sealed reaction kettle, crystallize at a temperature of 120°C and autogenous pressure for 48 hours, filter the resulting crystallized product, wash with water, and dry at 110°C for 120 minutes, and then at a temperature of 550°C Calcined for 3 hours to obtain titanium silicon material B. The sample is characterized by X-ray diffraction, Fourier transform infrared spectrum and ...

Embodiment 3

[0052] First, add 30 grams of tetramethyl orthosilicate and appropriate amount of tetrabutyl titanate into the aqueous solution of tetrapropylammonium hydroxide respectively, and stir them ultrasonically to make them evenly mixed to form two kinds of solutions. After mixing the above two kinds of solutions, add them to Continue ultrasonic stirring in the aqueous solution of tetradecyl trimethyl ammonium bromide to make it evenly mixed, in which tetramethyl orthosilicate, tetrabutyl titanate, tetrapropyl ammonium hydroxide, tetradecyl trimethyl bromide The molar ratio of ammonium chloride to water is 1:0.4:0.1:0.1:130. Put this mixed solution into a sealed stainless steel reaction kettle, first crystallize at a temperature of 80°C and an autogenous pressure for 5 hours, and then crystallize at a temperature of 160°C and an autogenous pressure for 24 hours, filter the crystallized product obtained, and wash with water , and dried at 110° C. for 120 minutes, and then fired at 550...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com