Preparation method of thermosetting type composite adhesive

A composite adhesive, thermosetting technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, adhesives, etc. Unable to guarantee the bonding fastness and other problems, to achieve the effects of excellent cupping properties, excellent bonding fastness and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

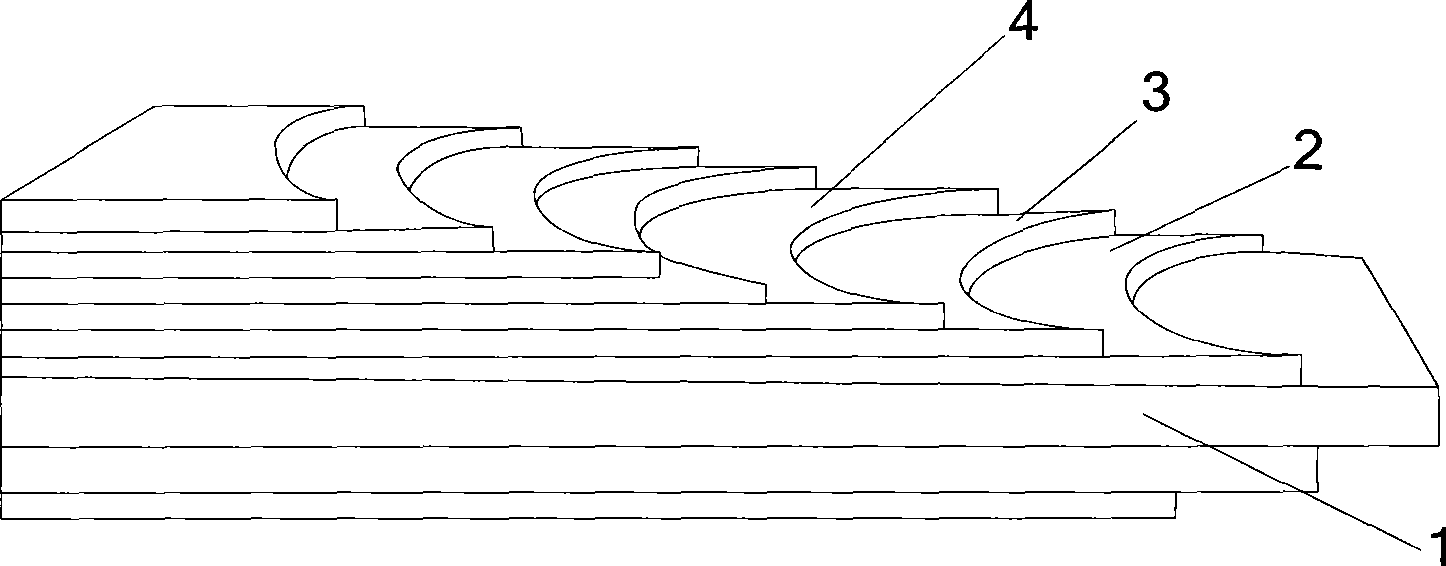

Image

Examples

Embodiment 1

[0021] This embodiment provides a method for preparing a thermosetting composite adhesive of the present invention. The prepared adhesive can be used to bond PVC and steel plates to make a composite board. The method includes:

[0022] (1) Preparation of polyester polyol:

[0023] a. Primary esterification:

[0024] Add 10-20 parts by mass of dimethyl terephthalate and 20-30 parts by mass of diethylene glycol into the polyester synthesis kettle, raise the temperature to 210-230°C, and react for 2-3 hours, completing once Esterification reaction, distilling off 3 to 7 parts by mass of methanol;

[0025] b. Secondary esterification:

[0026] Add 5 to 10 parts by mass of dimer acid, 10 to 20 parts by mass of isophthalic acid, 5 to 10 parts by mass of azelaic acid and 20 to 30 parts by mass of 1,3 butanediol to the above step a In the polyester synthesis kettle used for the primary esterification reaction, the temperature is raised to 210-230°C, and the reaction is carried out ...

Embodiment 2

[0040] This embodiment provides a method for preparing a thermosetting composite adhesive, and the prepared composite adhesive is used for bonding PVC and steel plates for compounding. The method includes:

[0041] (1) Preparation of polyester polyol:

[0042] The formula of each raw material is as follows:

[0043] Raw material ratio (parts by mass)

[0044] Dimethyl terephthalate 15

[0045] Diethylene glycol 25

[0046] Dimer acid 6

[0047] Isophthalic acid 14

[0048] Azelaic acid 5

[0049] 1,3 Butanediol 35

[0050] Preparation:

[0051] a. Primary esterification:

[0052] Add 15Kg of dimethyl terephthalate and 25Kg of diethylene glycol into the polyester synthesis kettle, raise the temperature to 225-230°C, react for 3 hours, distill off 5kg of methanol, and complete an esterification reaction;

[0053] b. Secondary esterification:

[0054] The dimer acid of 6Kg, the isophthalic acid of 14Kg, the azelaic acid of 5Kg and 35Kg of 1,3 butanediol are joined in th...

Embodiment 3

[0071] This embodiment provides a method for preparing a thermosetting composite adhesive, and the prepared composite adhesive is used for bonding PVC and steel plates for compounding. The method includes:

[0072] (1) Preparation of polyester polyol: refer to application example 1

[0073] The formula of each raw material is as follows:

[0074] Raw material ratio (parts by mass)

[0075] Dimethyl terephthalate 10

[0076] Diethylene glycol 30

[0077] Dimer acid 10

[0078] Isophthalic acid 10

[0079] Azelaic acid 10

[0080] 1,3 Butanediol 30

[0081] Preparation:

[0082] a. Primary esterification:

[0083] Add 10Kg of dimethyl terephthalate and 30Kg of diethylene glycol into the polyester synthesis kettle, raise the temperature to 225-230°C, react for 3 hours to complete an esterification reaction, and distill 3kg of methanol;

[0084] b. Secondary esterification:

[0085] Add 10Kg of dimer acid, 10Kg of isophthalic acid, 10Kg of azelaic acid and 30Kg of 1,3-bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com