Low-coke-ratio blast furnace ironmaking technique

A blast furnace ironmaking and coke ratio technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of high unit investment, high production cost, low single furnace output, etc., to save investment, improve productivity, and avoid the process of carbon deposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

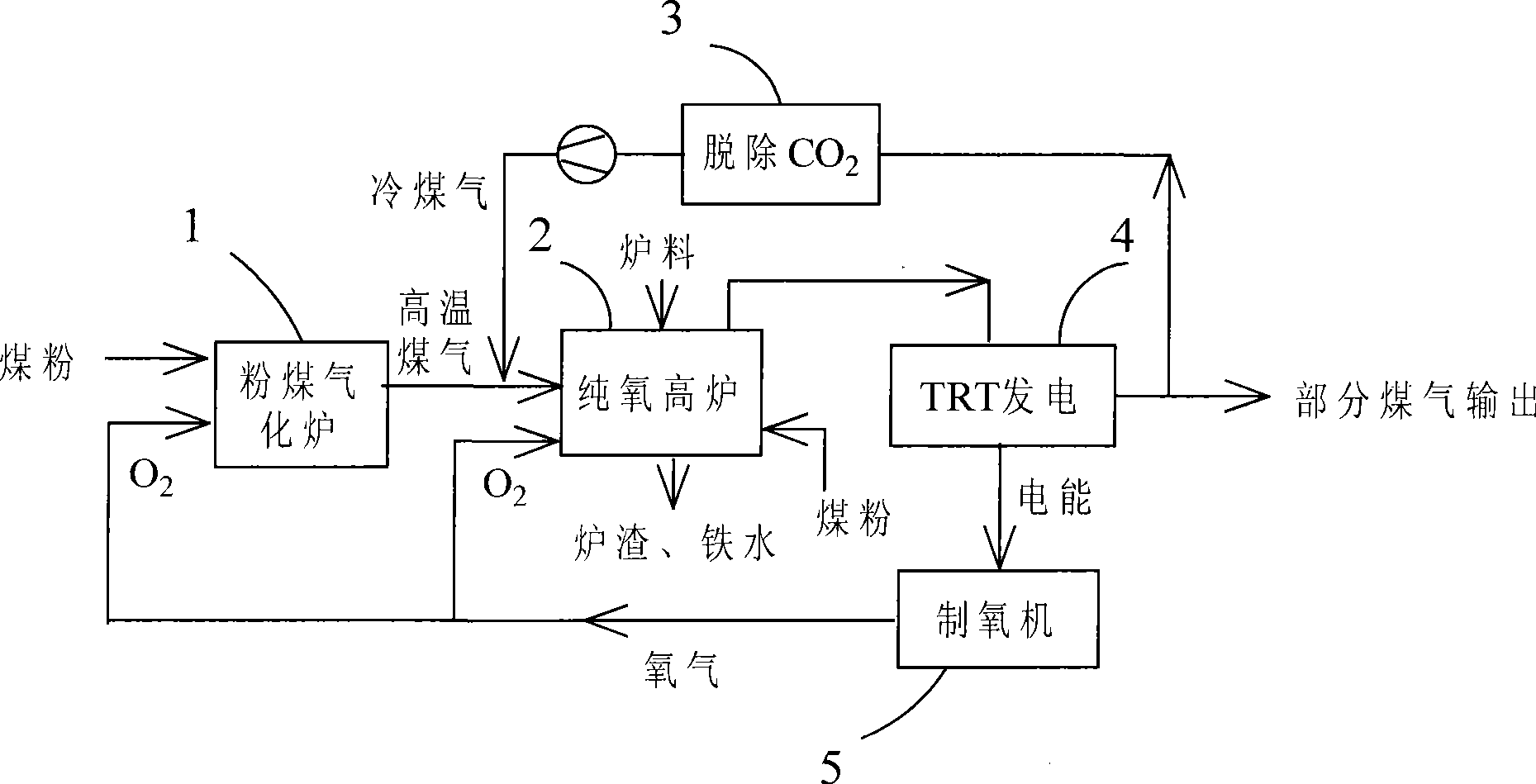

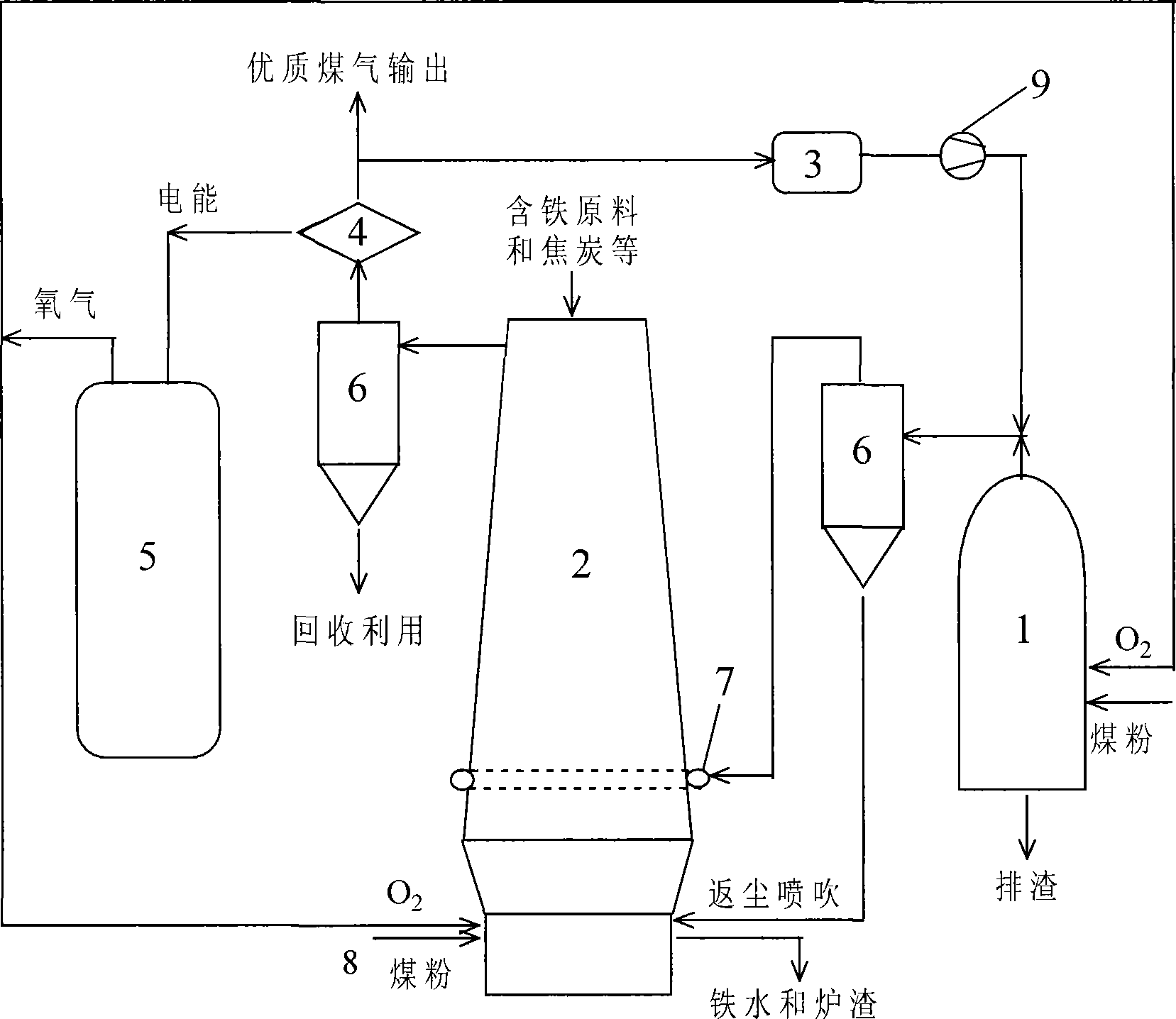

Method used

Image

Examples

Embodiment 1

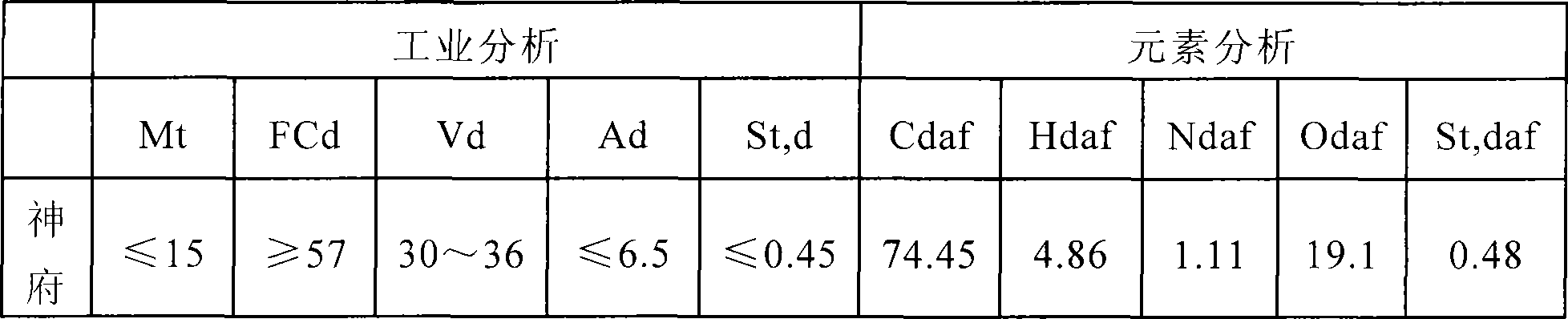

[0041] Some 2500m 3 A high-efficiency and environmentally-friendly blast furnace combining a blast furnace and a 2050t / d dry pulverized coal gasifier. The single-furnace gas output of the dry pulverized coal gasifier is 164000m 3 / h, the oxygen consumption of pulverized coal gasification is 47400m 3 / h, the coke ratio of the blast furnace is 200kg / t, the amount of pulverized coal injected by the tuyere is 100kg / t, and the amount of oxygen blown by the tuyere is 22000m 3 / h, the amount of top gas of the purifying blast furnace that is used for the quenching generation gas exchange is 180,000m 3 / h, the utilization factor of the blast furnace is 3.0t / m 3 .d, the iron output of the blast furnace is 7500t per day, and the amount of gas blown into the furnace body is 1323m3 / t iron.

[0042] The charge structure of the blast furnace is 80% of sintered ore, 10% of pellets, 10% of concentrated ore, average iron grade of 60%, slag binary basicity of 1.15, and secondary metallurgical coke w...

Embodiment 2

[0048] Some 1250m 3 A high-efficiency and environmentally friendly blast furnace combining a blast furnace and a 1050t / d dry pulverized coal gasifier. The single furnace gas output of the dry pulverized coal gasifier is 84000m 3 / h, the oxygen consumption of pulverized coal gasification is 24400m 3 / h, the coke ratio of the blast furnace is 190kg / t, the amount of pulverized coal injected at the tuyere is 100kg / t, and the amount of oxygen blown at the tuyere is 11000m 3 / h, the amount of top gas of the purifying blast furnace that is used for the quenching generation gas exchange is 95000m 3 / h, the utilization factor of the blast furnace is 3.4t / m 3 .d., the blast furnace produces 4250t of iron per day, and the amount of gas blown into the furnace body is 1322m 3 / t iron.

[0049] The charge structure of the blast furnace is 80% of sintered ore, 10% of pellets, 10% of concentrated ore, average iron grade of 60%, slag binary basicity of 1.20, and secondary metallurgical coke with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com