Compound coagulant made from fly ash and preparation method and application thereof

A technology of fly ash and coagulant, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems that have not been reported in the literature, and achieve the effects of low cost, shortened time and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1), Roasting:

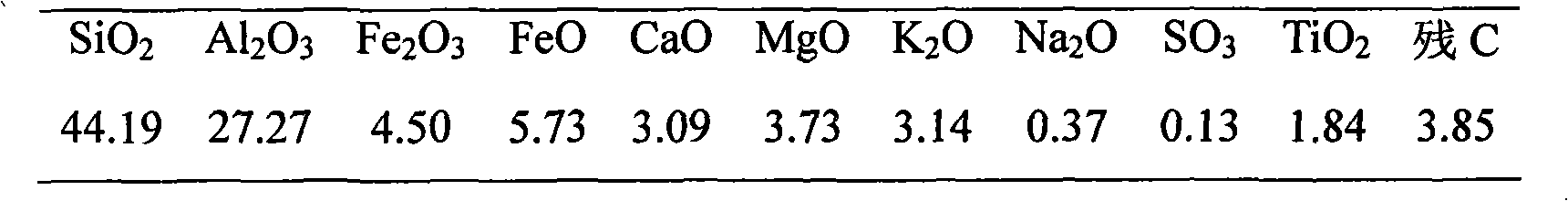

[0029] The fly ash from the power plant of Panzhihua Iron and Steel Company was used as the raw material, and its chemical composition is shown in Table 1.

[0030] Chemical composition / wt% of raw material fly ash of table 1

[0031]

[0032] Soda powder and fly ash with a mass content of 55% were evenly mixed, and 300 g of the mixture was placed in a SX2-10-13 high-temperature muffle furnace for roasting. Raise the temperature from room temperature to 850°C at a constant rate of 10°C / min, and keep the temperature for 30min at this calcination temperature.

[0033] (2), activation

[0034] After cooling in the furnace, crush it with a jaw crusher, and then mechanically activate it with an ND2-1L planetary ball mill. The rotation speed of the ball mill is 220rpm, the ratio of material to ball is 1:3, and the mechanical activation time is 2.5h.

[0035] After sieving, take the part with a particle size below 0.074mm as the leaching raw material for ...

Embodiment 2

[0043] (1), Roasting:

[0044] The fly ash from the power plant of Panzhihua Iron and Steel Company is used as raw material, and its chemical composition is shown in Table 1 in Example 1. Soda powder and fly ash with a mass content of 55% were evenly mixed, and 300 g of the mixture was placed in a SX2-10-13 high-temperature muffle furnace for roasting. Raise the temperature from room temperature to 850°C at a constant rate of 10°C / min, and keep the temperature for 30min at this calcination temperature.

[0045] (2), activation

[0046] After cooling in the furnace, crush it with a jaw crusher, and then mechanically activate it with an ND2-1L planetary ball mill. The rotation speed of the ball mill is 220rpm, the ratio of material to ball is 1:3, and the mechanical activation time is 2.5h.

[0047] After sieving, take the part with a particle size below 0.074mm as the leaching raw material for the next two steps.

[0048] (3), pickling

[0049] The leaching is carried out i...

Embodiment 3

[0055] (1), Roasting:

[0056] The fly ash from the power plant of Panzhihua Iron and Steel Company is used as raw material, and its chemical composition is shown in Table 1 in Example 1.

[0057] Soda powder and fly ash with a mass content of 55% were evenly mixed, and 300 g of the mixture was placed in a SX2-10-13 high-temperature muffle furnace for roasting. Raise the temperature from room temperature to 850°C at a constant rate of 10°C / min, and keep the temperature for 30min at this calcination temperature.

[0058] (2), activation

[0059] After cooling in the furnace, crush it with a jaw crusher, and then mechanically activate it with an ND2-1L planetary ball mill. The speed of the ball mill is 220rpm, the ratio of material to ball is 1:3, and the mechanical activation time is 2.5h.

[0060] After sieving, take the part with a particle size below 0.074mm as the leaching raw material for the next two steps.

[0061] (3), pickling

[0062] The leaching is carried out i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com