PEG grafted polysulphone or polyether sulphone hollow fibrous membrane, preparation method and application thereof

A polyethersulfone and fiber membrane technology, applied in the intersection of material science and tissue engineering, in the field of membrane chemistry, can solve problems such as inability to deduce membrane parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

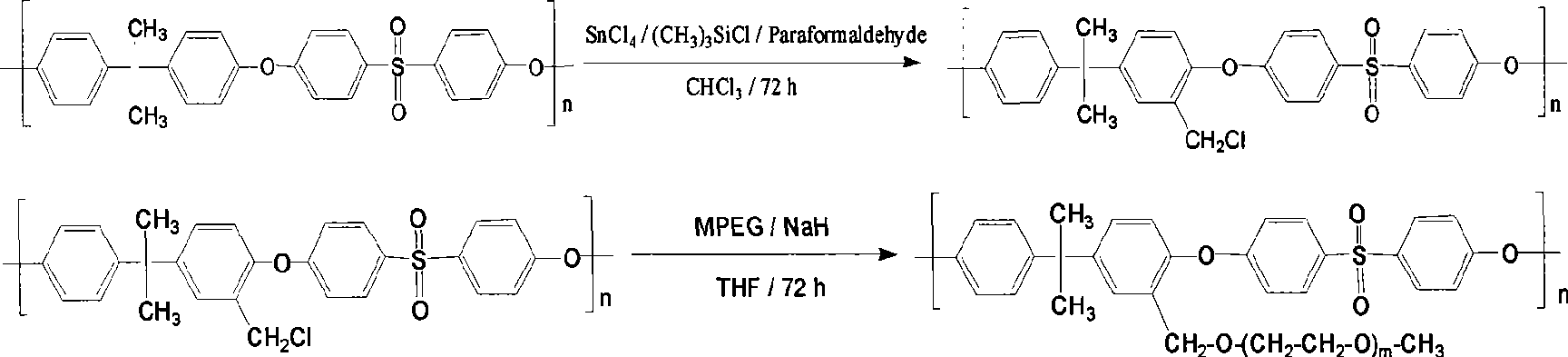

[0031] The preparation method of the PEG-grafted polysulfone or polyethersulfone hollow fiber membrane comprises the following steps:

[0032] a) After the compound represented by molecular formula I and the compound represented by molecular formula II are mixed in a ratio of 1:3 to 9, they are dissolved in a solvent with a weight ratio of 15 to 30%. The solvent is N-methylpyrrolidone and dimethylformamide , dimethylacetamide and dimethyl sulfoxide or a mixture of several;

[0033] b) stirring, dissolving for 10 to 12 hours, degassing, and obtaining the spinning stock solution;

[0034] c) Two concentric hollow fiber spinnerets are used to extrude the spinning dope through the spinnerets. The ambient temperature is 20-25°C, the relative humidity is 30-80%, and the extrusion speed is 5-20ml / min. The as-spun fibers go through 10-30cm in the environment and then solidify and form in a water bath with a temperature of 50-80°C. The line speed is 5-40m / min.

[0035] The hollow fi...

Embodiment 1

[0046] The PEG molecular weight is 350, the PEG-polysulfone graft product of graft rate 32%, mixes with polysulfone by the ratio of 1:3, and dissolves in N-methylpyrrolidone by 15% (w / v), stirs Let it dissolve completely for 12 hours and remove the air bubbles. When the room temperature is 20°C and the relative humidity is 50%, the spinning solution is extruded through two concentric hollow fiber spinnerets at a speed of 5ml / min. It is solidified and formed in water at 50°C, and the fluid linear velocity is 5.5m / min.

[0047] The inner diameter of the obtained novel hollow fiber membrane is 1000 μm, the wall thickness is 100 μm, the porosity detected by mercury porosimetry is 78%, the average pore diameter is 0.8 μm, and no albumin interception can be detected.

Embodiment 2

[0049] The PEG-polyethersulfone grafted product with a molecular weight of 750 and a grafting rate of 16% is mixed with polyethersulfone at a ratio of 1:5 and dissolved in dimethylacetamide at 20% (w / v) , stirred for 12 hours to dissolve it completely, and remove air bubbles. When room temperature is 25°C and relative humidity is 70%, the spinning solution is extruded through two concentric hollow fiber spinnerets at a speed of 12ml / min. It is solidified and formed in water at 75°C, and the fluid linear velocity is 10m / min.

[0050] The inner diameter of the obtained novel hollow fiber membrane is 700 μm, the wall thickness is 100 μm, the porosity detected by mercury porosimetry is 74%, the average pore diameter is 0.11 μm, and the albumin rejection rate is 65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com