Method for electrochemically disinfecting gas diffusion electrode system

A disinfection method and diffusion electrode technology are applied in the fields of electrochemical water treatment and disinfection using a gas diffusion electrode system, and electrochemical water treatment and disinfection. Achieve the effect of good treatment effect, wide application range and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

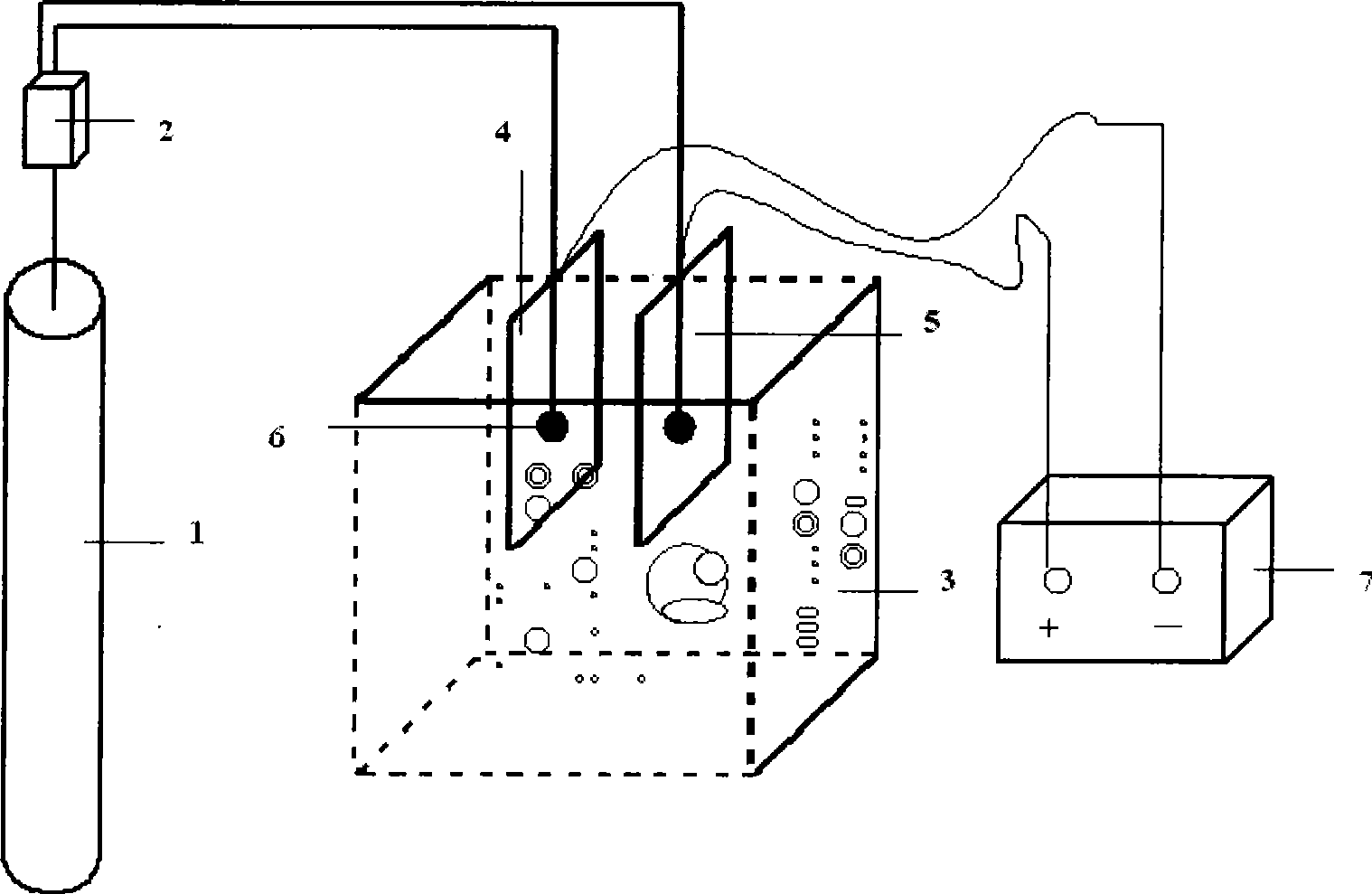

Image

Examples

Embodiment 1

[0025] Embodiment 1 carries out electrochemical disinfection with the composite gas diffusion electrode not containing pore-forming agent and catalyst as cathode

[0026] The present invention is to the total number of bacteria containing 10 6 The water distribution of CFU / mL is electrolyzed under the action of a composite gas diffusion cathode without pore-forming agents and catalysts, and the current density is controlled at 6.6mA / cm 2 , the oxygen flow rate reacted at 30L / h, samples were taken at different times, and the total number of bacteria was detected after 24 hours of cultivation by the standard plate method. It can be seen from the table below that when the energy consumption is equal to 0.62W·h / L, the sterilization efficiency is only 63.27%.

[0027] time (min) Energy Consumption(W·h / L) Bactericidal efficiency (%) 5 0.10 7.14 10 0.21 19.39 15 0.31 28.57 20 0.41 37.76 25 0.52 50.00 30 0.62 63.27

Embodiment 2

[0028] Example 2 contains pore-forming agent NH 4 HCO 3 Composite gas diffusion electrode as cathode for electrochemical disinfection

[0029] The present invention is to the total number of bacteria containing 10 6 The CFU / mL water distribution is electrolyzed under the action of a composite gas diffusion electrode with a pore-forming agent content of 30%. Other conditions are the same as application example 1. It can be seen from the table below that when the energy consumption is equal to 0.63W·h / L, the sterilization efficiency reaches more than 77%.

[0030] time (min) Energy Consumption(W·h / L) Bactericidal efficiency (%) 5 0.10 25.00 10 0.21 39.58 15 0.31 50.00 20 0.42 58.33 25 0.52 66.67 30 0.63 77.92

[0031] Under the action of a composite diffusion electrode with a pore-forming agent content of 40%, other reaction conditions are the same as above, and the electrolysis is carried out to obtain the following resu...

Embodiment 3

[0038] Embodiment 3 carries out electrochemical disinfection with the composite gas diffusion electrode containing catalyst Pt as cathode

[0039] The present invention electrolyzes the distribution water containing 106 CFU / mL of total bacteria under the action of a composite gas diffusion electrode with a catalyst Pt content of 2‰. Other conditions are the same as application example 1. It can be seen from the table below that when the energy consumption is equal to 0.58W·h / L, the sterilization efficiency reaches more than 79%.

[0040] time (min) Energy Consumption(W·h / L) Bactericidal efficiency (%) 5 0.10 14.63 10 0.20 32.93 15 0.29 48.78 20 0.39 58.54 25 049 67.07 30 0.58 79.27

[0041] Under the action of a composite diffusion electrode with a catalyst Pt content of 3‰, other reaction conditions were the same as above, and the electrolysis was carried out to obtain the following results:

[0042] time (min)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com