Method for preparing unsaturated and conjugated diolefin-nitrile copolymer

The technology of conjugated diene nitrile copolymer and conjugated diene is applied in the field of preparation of unsaturated conjugated diene nitrile copolymer, can solve problems such as long vulcanization time of rubber, and achieve good processing performance and fast vulcanization speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

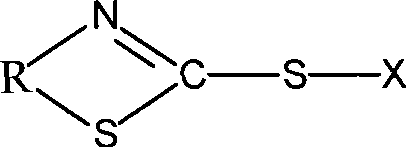

Method used

Image

Examples

Embodiment 1

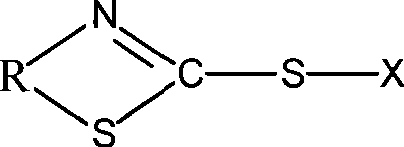

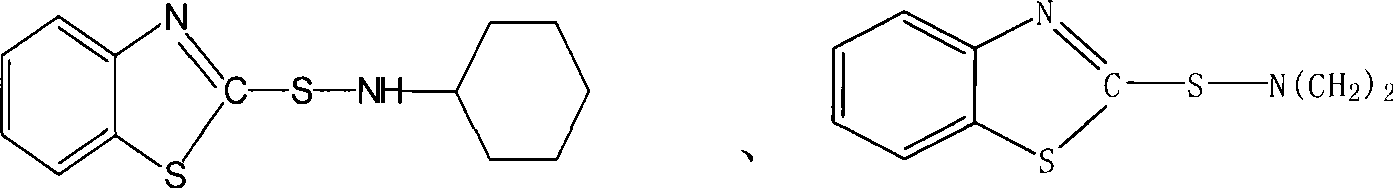

[0028] The polymerization reaction was carried out in a 30L autoclave. The added amount of each monomer adjuvant is based on 100 parts of total monomer weight (the same below). At the beginning of the polymerization reaction, add 300 parts of desalinated water, 2.0 parts of sodium dodecylbenzene sulfonate soap, 0.005 parts of white block, 0.001 parts of EDTA-Fe, 0.001 parts of EDTA-4Na salt, and 30 parts of monomer acrylonitrile. Add 0.2 parts of t-dodecyl mercaptan and 0.3 parts of 2-mercaptobenzothiazole to the polymerization kettle. After vacuuming, replace with nitrogen three times, then add 70 parts of monomer butadiene and 0.03 parts of sodium dithionite as the deoxidizer, When the temperature of the polymerization kettle reaches 12°C, add 0.06 parts of initiator dicumyl peroxide to start the polymerization reaction. When the polymerization conversion rate finally reaches 90%, add 0.2 part of terminator hydroxylamine sulfate, stir for half an hour to cool down and discharge....

Embodiment 2

[0030]The polymerization reaction was carried out in a 30L autoclave. At the beginning of the polymerization reaction, add 300 parts of desalinated water, 3.0 parts of sodium dodecylbenzene sulfonate soap, 0.005 parts of white block, 0.001 parts of EDTA-Fe, 0.001 parts of EDTA-4Na salt, 28 parts of monomer methyl Acrylonitrile, 0.4 parts of 1,1,3,3-tetramethyl-1-butanethiol and 0.2 parts of 2-mercaptobenzothiazole were added to the polymerization vessel, after vacuuming, replaced with nitrogen three times, and then added 72 parts Monomer butadiene, 0.03 parts of oxygen scavenger sodium hydrosulfite, when the temperature of the polymerization kettle reaches 12 ℃, add 0.08 parts of initiator dicumyl peroxide, start the polymerization reaction, and measure every 4 hours during the polymerization process For the primary dry matter, when the polymerization conversion rate reaches 30%, add the molecular weight regulator 0.05 parts 1,1,3,3-tetramethyl-1-butanethiol and 0.15 parts 2-merca...

Embodiment 3

[0032] The polymerization reaction was carried out in a 30L autoclave. At the beginning of the polymerization reaction, 500 parts of desalted water, 3.0 parts of potassium oleate soap, 0.03 parts of triethanolamine, 32 parts of monomer acrylonitrile, 0.4 parts of t-dodecyl mercaptan and 0.25 parts of tert-butyl-2-benzo Thiazole sulfenamide was added to the polymerization vessel, after vacuuming, replaced with nitrogen three times, and then 68 parts of monomer 1,3 pentadiene and 0.05 parts of sodium dithionite were added. When the temperature of the polymerization vessel reached 30°C, Add 0.05 parts of the initiator potassium persulfate solution to start the polymerization reaction. During the polymerization process, the dry matter is measured every 4 hours. When the polymerization conversion rate reaches 55%, add the molecular weight regulator 0.05 parts t-dodecyl mercaptan and 0.2 parts t-butyl-2-benzothiazole sulfenamide. Continue the reaction until the final conversion rate rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com