Preparation method of polycarboxylic acids high efficiency water reducer

A high-efficiency water-reducing agent and polycarboxylic acid-based technology, applied in the field of chemical preparation, can solve the problems that cannot meet the needs of the development of high-performance concrete, and achieve the effects of increased water-reducing rate, simplified production process, and long release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

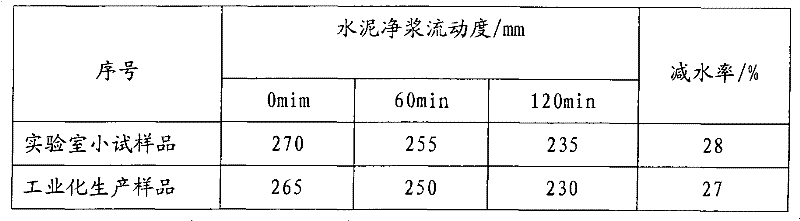

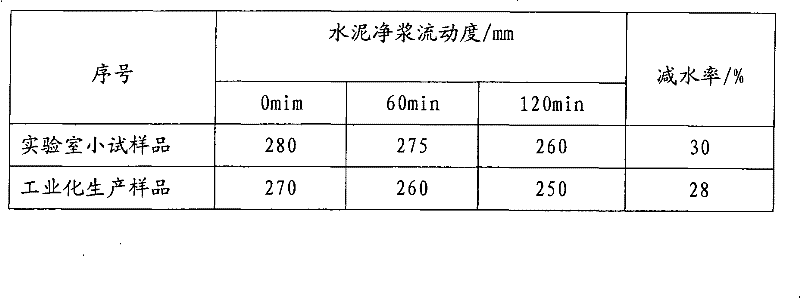

Embodiment 1

[0017] Preparation of polycarboxylic acid water reducing agent:

[0018] The first step, the esterification reaction: Take 300g (0.1mol) of MPEG (molecular weight 3000) and put it into a 1000ml four-necked flask equipped with a breakpoint thermometer, condenser, and stirrer. When the reaction temperature reaches about 70℃, add resistance Polymerizing agent hydroquinone and hydroquinone monomethyl ether each 0.4g, stir well, then add 57.6g (0.8mol) of acrylic acid, continue to heat up to 90℃, add 4.29g of catalyst concentrated sulfuric acid, and pass nitrogen as The water-carrying agent is reacted at 120°C for 10 hours to obtain the esterified macromonomer, namely methoxy polyethylene glycol monomethyl ether acrylate.

[0019] The second step, polymerization reaction: add a proper amount of distilled water into a 1000ml four-necked flask equipped with a breakpoint thermometer, a condenser, and a stirrer, and then pass in nitrogen. At 85°C, use a constant flow pump to dropwise add 66...

Embodiment 2

[0022] The industrial production of the esterified macromonomer of the present invention is as follows:

[0023] (1) Detection of main raw materials: determination of MPEG hydroxyl value, determination of acrylic acid purity

[0024] (2) The operation of production equipment: including the calibration of thermometers, temperature control equipment, and the sealing of pipelines and reactors.

[0025] (3) Weigh 990kg of methoxy polyethylene glycol monomethyl ether (MPEG) and put it into the reactor. When the temperature rises to about 70℃, add the inhibitor hydroquinone and hydroquinone monomethyl ether. 2.64kg, stir evenly, and add 190.1kg of acrylic acid.

[0026] (4) When the temperature is raised to 90°C, add 14.16kg of concentrated sulfuric acid as a catalyst, and pass in nitrogen as a water-carrying agent. After reacting at 120°C for 10 hours, an esterified macromonomer, methoxy polyethylene glycol monomethyl ether acrylic acid, is obtained. ester.

[0027] (5) The prepared esteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com