Method for treating wastewater in textile printing and dyeing industry

A technology for industrial wastewater and treatment methods, which is applied in the fields of textile industrial wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of large fluctuations in water quality, poor biodegradability, and toxic and harmful substances in wastewater, etc. problems, to achieve the effects of CODcr reduction, biodegradability improvement, and impact load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In an industrial area of a certain city, the wastewater from several textile printing and dyeing factories was collected for treatment. The two factories mainly process pure cotton, with an output of several million meters, without alkali recovery. The main dyes are reactive dyes, shihlin dyes, paints and a small amount of sulfur dyes. The treated water volume is 25000m 3 / day, the water quality of mixed wastewater from these two plants is shown in Table 1.

[0032] Table 1 Water quality indicators of mixed wastewater

[0033] project

Range of water quality change

average

COD Cr (mg / L)

236.67~4037.62

2500

BOD 5 (mg / L)

105.78~2050.56

650

SS(mg / L)

59~5944

600

Chroma (times)

27.78~5000

1000

pH value

12.0~14.0

13.0

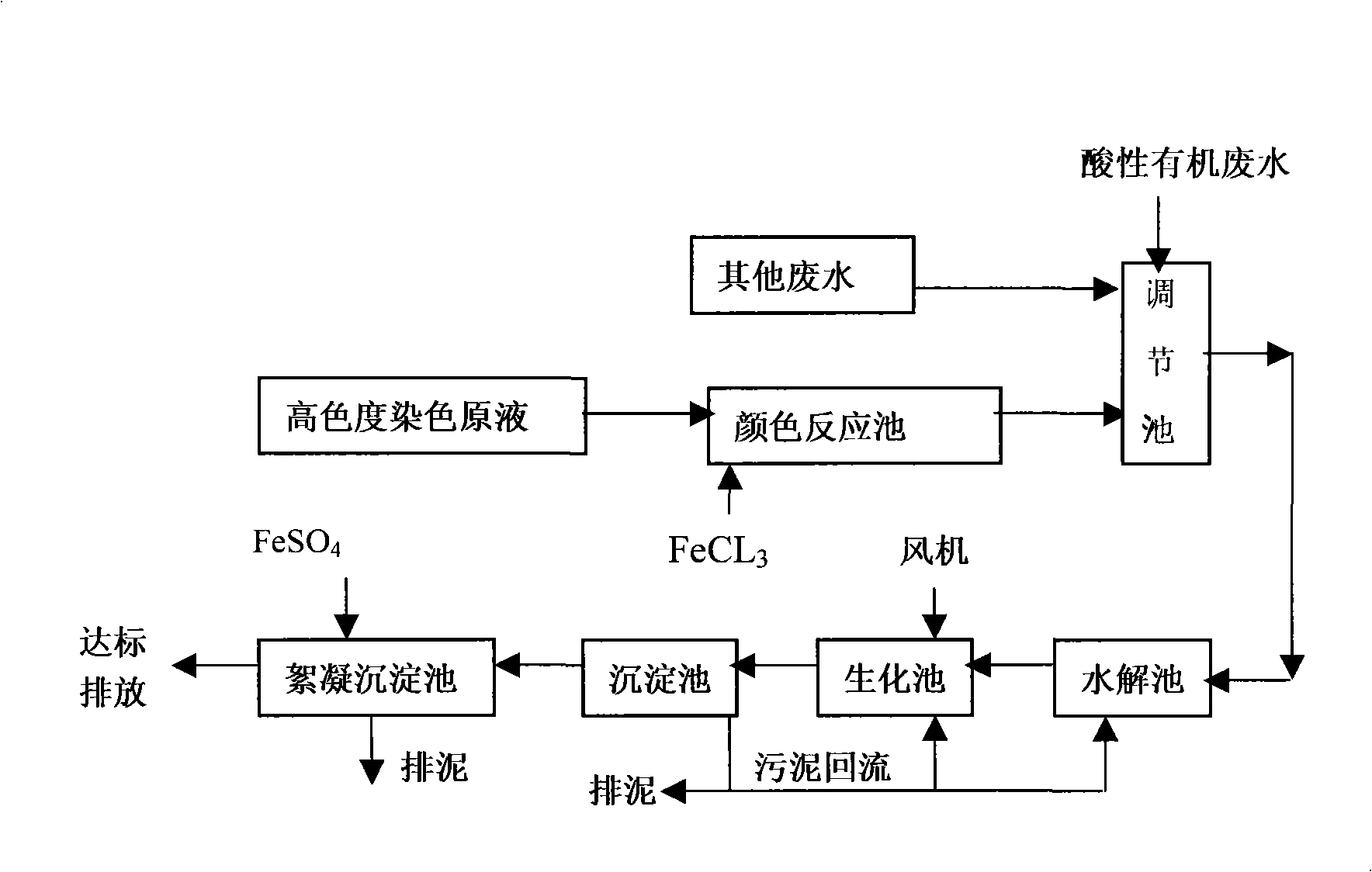

[0034] Such as figure 1 Shown, the present invention adopts following steps:

[0035] A. Pretreatment of high chroma dyeing stock s...

Embodiment 2

[0045] During the homogenization treatment, the volume ratio between the product of step A, other waste water and waste liquid and the externally introduced organic waste water is 2:1:0.05, and other process conditions are the same as in Example 1. The water quality of the effluent after treatment complies with the Class I standard in Table 3 of GB4287-92 "Discharge Standard of Water Pollutants for Textile Dyeing and Finishing Industry".

Embodiment 3

[0047] During the homogenization treatment, the volume ratio between the product of step A, other waste water and waste liquid and the externally introduced organic waste water is 5:1:0.01, and other process conditions are the same as in Example 1. The water quality of the effluent after treatment complies with the Class I standard in Table 3 of GB4287-92 "Discharge Standard of Water Pollutants for Textile Dyeing and Finishing Industry".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com