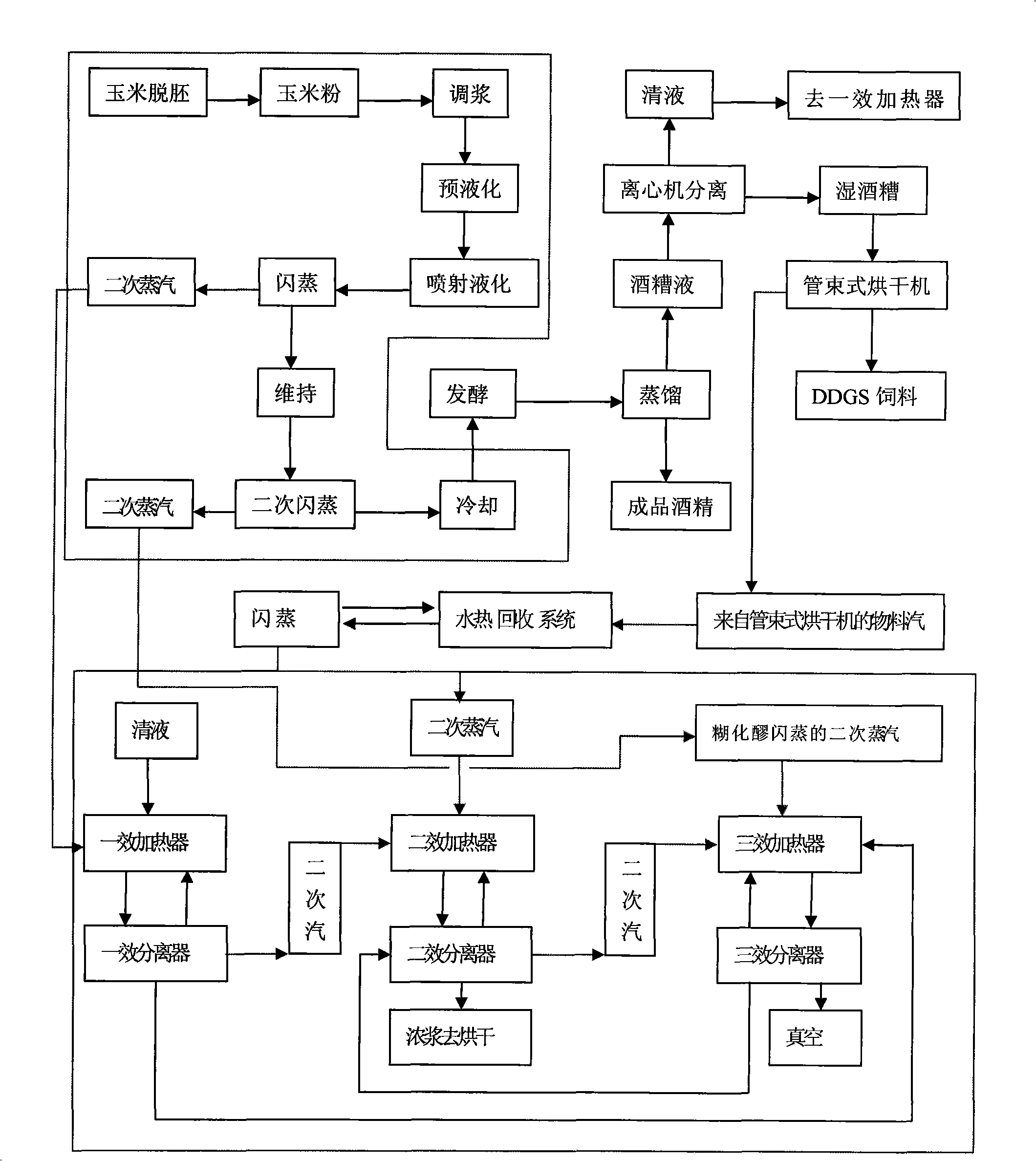

Technology for coupling the liquefaction process of corn alcohol and the concentration process of vinasse clear liquid

A clear liquid and process technology, which is applied in the coupling field of corn alcohol production liquefaction process and distiller's grain clear liquid concentration process, can solve the problems of high investment and operating costs of evaporation concentration, high raw material consumption, low gelatinization rate, etc., and achieve soluble solids Concentration increases, reducing the amount of distiller's grain wastewater, and facilitates the effect of evaporation and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

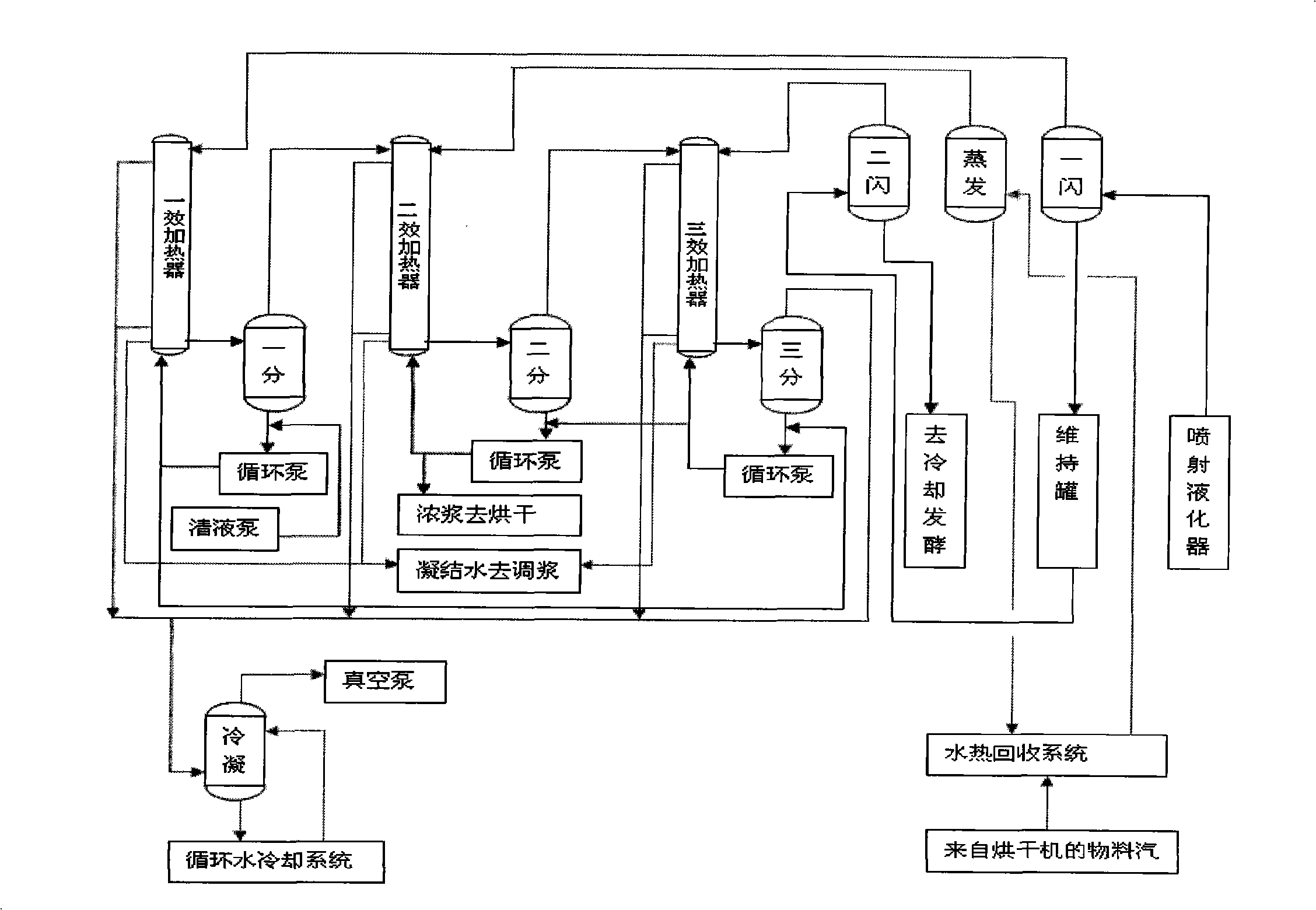

[0026]In the coupling technology of the corn alcohol production liquefaction process and distiller's grains clear liquid concentration process in this embodiment, the heater is connected to the flash tank through a pipeline, and the flashed secondary steam provides a heat source for the clear liquid evaporation and concentration through the pipeline, and at the same time, the vacuum pump is used for cleaning After the vacuum is provided by the liquid concentration system, the vacuum is passed to the flash tank through the pipeline to provide vacuum for flash evaporation. The coupling process of this embodiment includes the following steps:

[0027] (1) Degerming the corn and pulverizing it into corn flour, the consumption of corn raw material is 12.7 tons / hour;

[0028] (2) Slurry the corn flour, pre-liquefy it and then spray it to get liquefied mash. The temperature of the sprayed liquefaction is 115℃~135℃ and the pressure is 0.1~0.15MPa; during the process of spraying liquef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com