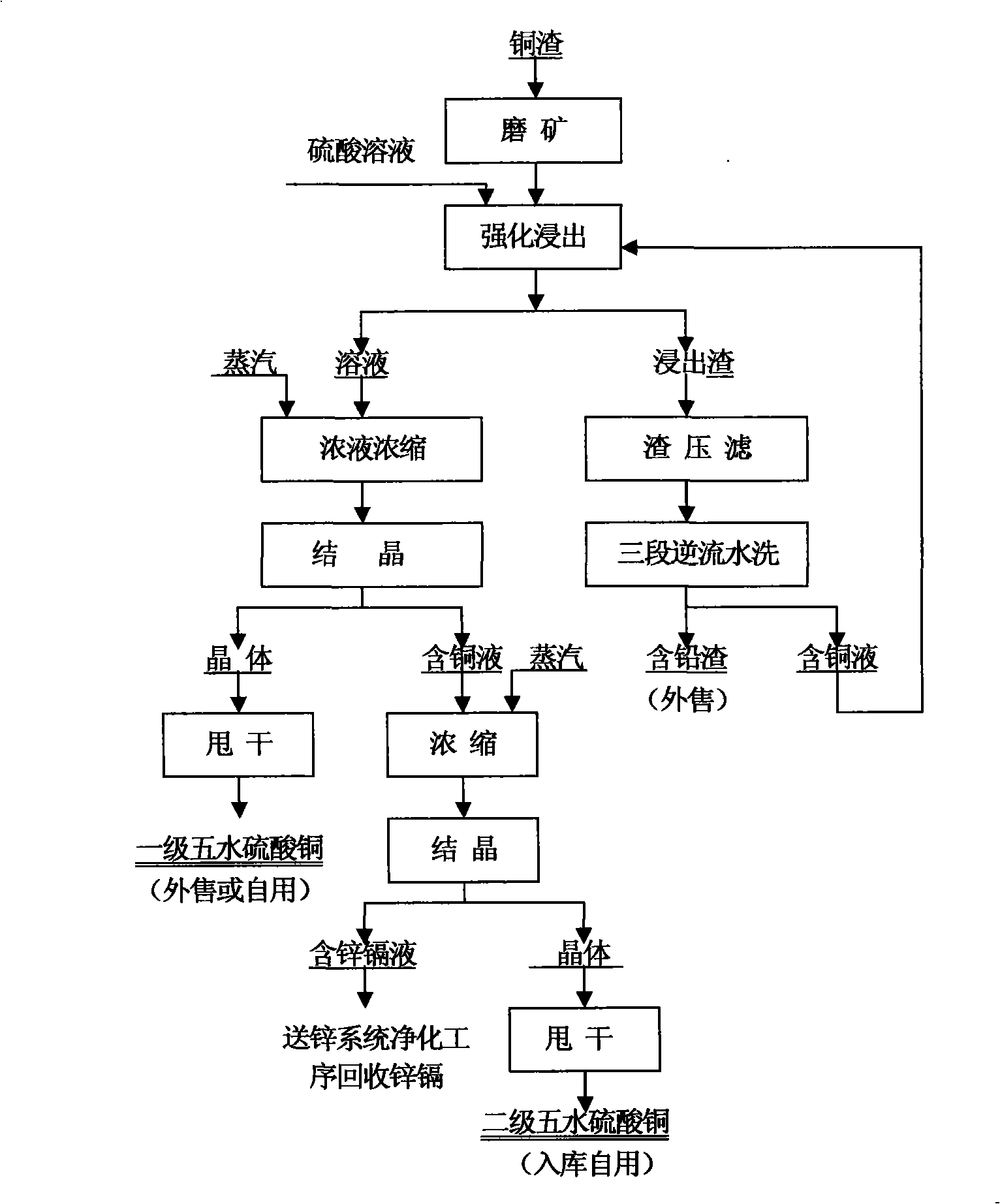

Process method for producing copper sulfate by intensified leaching of copper-containing materials

A technology that strengthens leaching and process methods, and is applied in the field of comprehensive recycling of non-ferrous metal smelting slag, which can solve the problems of large environmental pollution, high energy consumption, and short process, and achieve low environmental pollution, increased leaching rate, and short production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

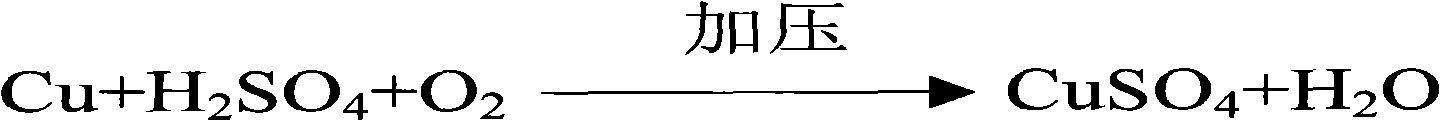

Method used

Image

Examples

Embodiment 1

[0028] Example 1: 42.35% copper, 4.98% zinc, 1.1% iron, 130kg dry weight, 42.69% copper slag was added to 1m 3 In the autoclave, feed more than 90% pure oxygen, the initial acid concentration is 160g / L, the liquid-solid ratio is 4:1, the leaching pressure is 1.0Mpa, the leaching temperature is 150°C, the rotation speed is 350r / min, and the leaching time is 3h. Get Cu 2+ 640L of leaching solution of 69g / L, 57.55kg of leaching residue, of which the leaching residue contains 5.34% Cu, 1.93% Zn, 1.74% iron, and the leaching rate of copper reaches 94.42%.

[0029] Add 20g / L polyacrylamide flocculant when the leachate is soaked at 60°C, clarification time is 3h, clarification and centrifugal filtration, concentration to remove calcium and magnesium, concentration time is 5-7h, after concentration, the specific gravity of the liquid is controlled to 1.42 and crystallization begins, the crystallization filtration temperature is 75°C, once Crystalline copper sulfate pentahydrate 110.8...

Embodiment 2

[0031] Example 2: 46.35% copper, 4.68% zinc, 1.23% iron, 120kg dry weight, 41.34% copper slag was added to 1m 3 In the autoclave, feed more than 90% pure oxygen, the initial acid concentration is 200g / L, the liquid-solid ratio is 3:1, the pressure is 1.1Mpa, the leaching temperature is 100°C, the rotating speed is 350r / min, and the leaching time is 3h, the obtained Cu 2+ 540L of leaching solution of 74.36g / L, 45.72kg of leaching residue, of which the leaching residue contains 1.74% Cu, 0.44% Zn, 0.73% iron, and the leaching rate of copper reaches 98.40%.

[0032] Add 5g / L polyacrylamide flocculant when the leachate is soaked at 70°C, clarification time is 1h, clarification and centrifugal filtration, concentration to remove calcium and magnesium, concentration time is 5-7h, after concentration, the specific gravity of the liquid is controlled to 1.45 and crystallization begins, the crystallization filtration temperature is 80°C, once Crystalline copper sulfate pentahydrate 11...

Embodiment 3

[0034] Example 3: 36.85% copper, 5.44% zinc, 1.34% iron, 140kg dry weight, 47.69% copper slag were added to 1m 3 In the autoclave, feed more than 90% pure oxygen, the initial acid concentration is 180g / L, the liquid-solid ratio is 7:1, the pressure is 1.2Mpa, the leaching temperature is 80°C, the rotating speed is 300r / min, and the leaching time is 2.5h. Get Cu 2+ 550L of 75g / L leachate, 55.44kg of leaching residue, of which the leaching residue contains 3.44% Cu, 0.64% Zn, 0.98% iron, and the copper leaching rate reaches 96.30%.

[0035] Add 10g / L3 when the leach solution is soaked at 80°C #Flocculant, clarification time 2h, clarification and centrifugal filtration, concentration and removal of calcium and magnesium, concentration time 5-7h, after concentration, the specific gravity of the liquid is controlled to 1.30 and crystallization begins, the crystallization and filtration temperature is 85°C, the first crystallization of copper sulfate pentahydrate is 111.04kg, coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com