Dielectric ceramic and capacitor

A dielectric and capacitor technology, which is applied in the direction of fixed capacitor dielectric, fixed capacitor parts, ceramics, etc., can solve the problems of inability to meet the performance of bypass capacitors, low storage capacity, and low relative dielectric constant of dielectric ceramics, etc. problem, to achieve the effect of small temperature change rate, suppression of noise generation, and reduction of spontaneous polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

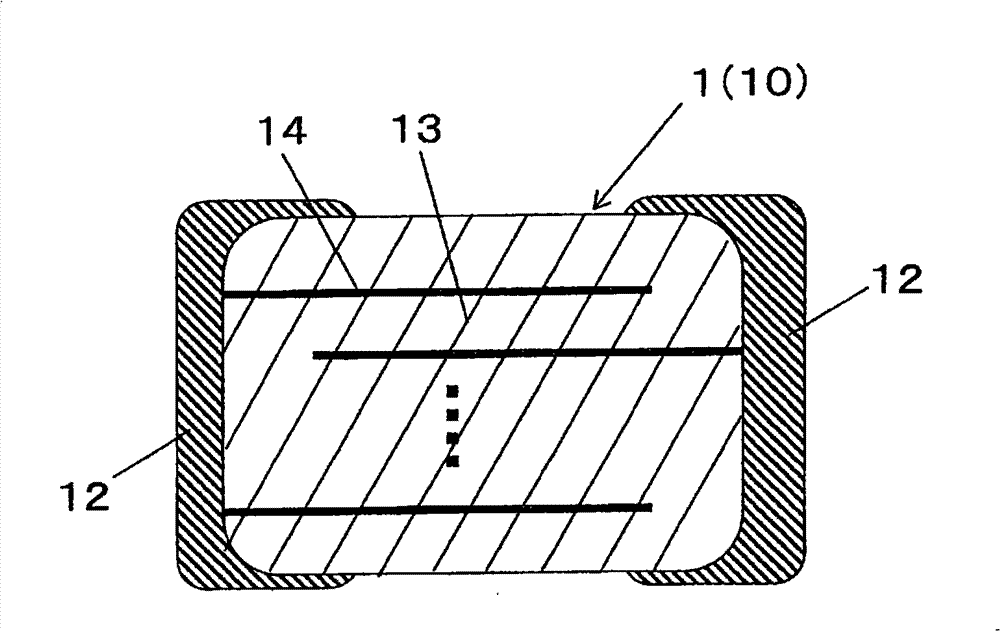

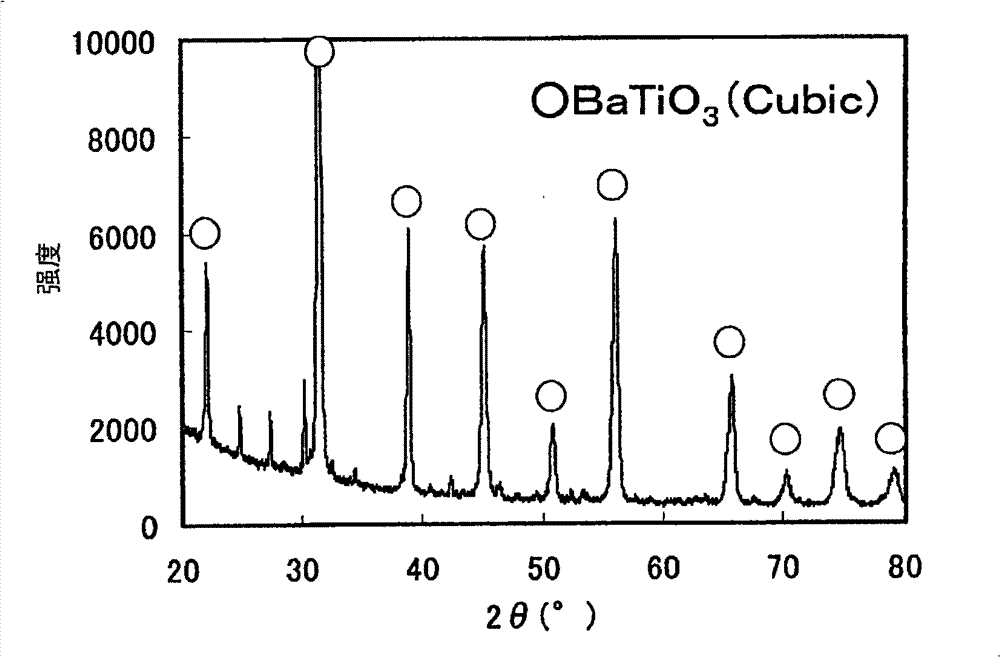

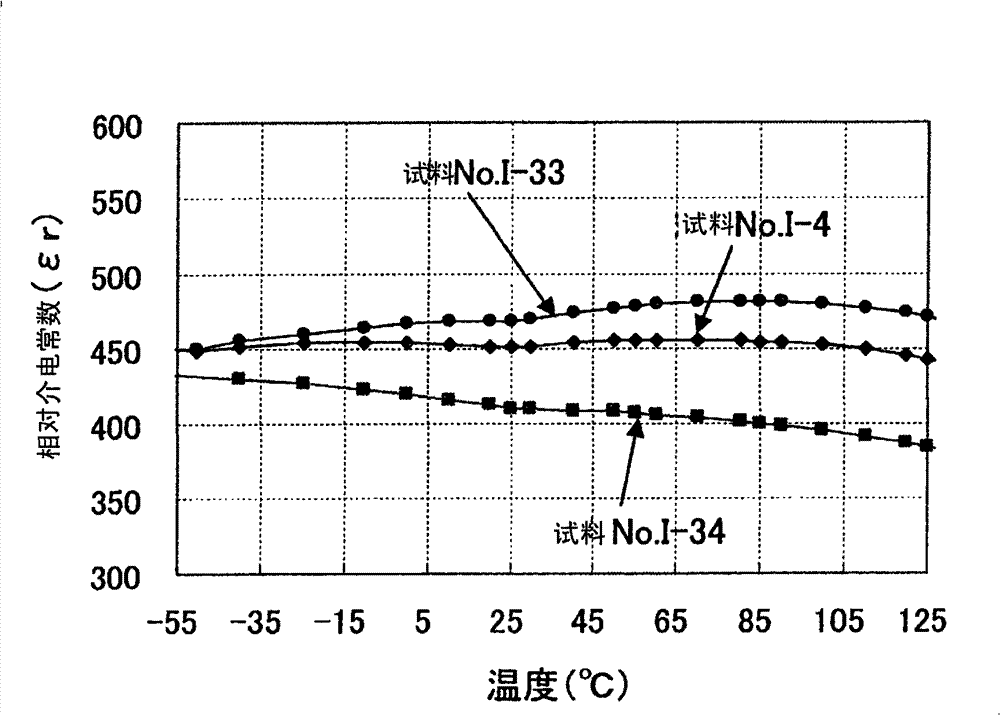

[0033] Hereinafter, the dielectric ceramic and the capacitor according to the first embodiment of the present invention will be described in detail with reference to the drawings. figure 1 is a schematic cross-sectional view showing the capacitor of this embodiment. The dielectric ceramic of this embodiment is mainly composed of barium titanate, which contains magnesium, yttrium, manganese, and niobium. The content thereof contains 0.01 to 0.06 moles of magnesium in terms of MgO relative to 1 mole of barium. 2 o 3 In terms of conversion, 0.0007 to 0.03 moles of yttrium are contained, and in terms of MnO conversion, 0.0002 to 0.03 moles of manganese are contained, and Nb 2 o 5 In conversion, 4.2 to 33.3 parts by mass of niobium are contained.

[0034] In addition, the dielectric ceramic of this embodiment is composed of crystal grains mainly composed of barium titanate and grain boundary phases formed between the crystal grains. The grain boundary phase is an amorphous phas...

no. 2 approach

[0065] Next, a second embodiment of the present invention will be described. The dielectric ceramic of the present embodiment contains barium titanate as the main component, and contains magnesium, yttrium, manganese, niobium, silicon and boron, and its content is 0.01 to 0.01 to 100 mg of magnesium in terms of MgO relative to 1 mole of barium. 0.06 mol to Y 2 o 3 In terms of conversion, 0.0007 to 0.03 moles of yttrium are contained, and in terms of MnO conversion, 0.0002 to 0.03 moles of manganese are contained, and Nb 2 o 5 In terms of conversion, it contains 4.2 to 33.3 parts by mass of niobium, expressed as SiO 2 In terms of conversion, it contains 0.73 to 6.3 parts by mass of silicon, expressed as B 2 o 3 In conversion, 0.31 to 2.1 parts by mass of boron is contained.

[0066] In addition, the dielectric ceramic according to this embodiment includes crystal grains mainly composed of barium titanate and grain boundary phases formed between the crystal grains, and the...

no. 3 approach

[0091] Next, a third embodiment of the present invention will be described. The dielectric ceramic of the present embodiment contains barium titanate as the main component, and contains magnesium, yttrium, manganese, niobium, silicon, and lithium, and the content thereof contains 0.01 to 0.01 to 1,000 mg of magnesium in terms of MgO relative to 1 mole of barium. 0.06 mol to Y 2 o 3 In terms of conversion, 0.0007 to 0.03 moles of yttrium are contained, and in terms of MnO conversion, 0.0002 to 0.03 moles of manganese are contained, and Nb 2 o 5 In terms of conversion, it contains 4.2 to 33.3 parts by mass of niobium, expressed as SiO 2 In terms of conversion, it contains 0.73 to 6.3 parts by mass of silicon, and Li 2 In terms of O, 0.31 to 2.1 parts by mass of lithium is contained.

[0092] In addition, the dielectric ceramic according to this embodiment includes crystal grains mainly composed of barium titanate and grain boundary phases formed between the crystal grains, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com