Novel drying agent

A desiccant, a new type of technology, applied in other chemical processes, separation of dispersed particles, prevention of condensed water formation, etc., can solve problems such as difficult to increase production and large-scale touch production, pollute the environment, rise in raw material prices, etc., to achieve a good choice Type and selective adsorption characteristics, simple process operation, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

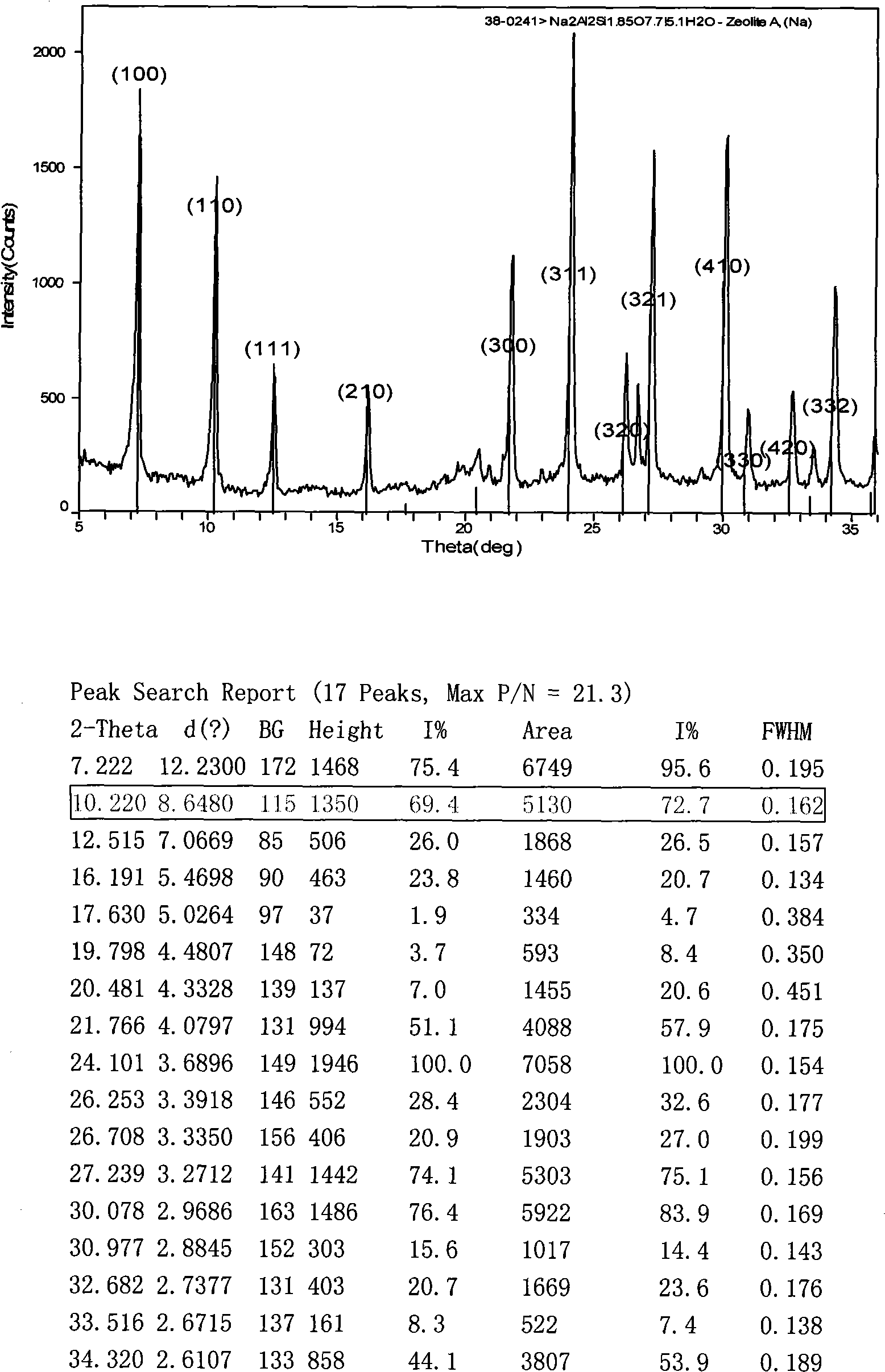

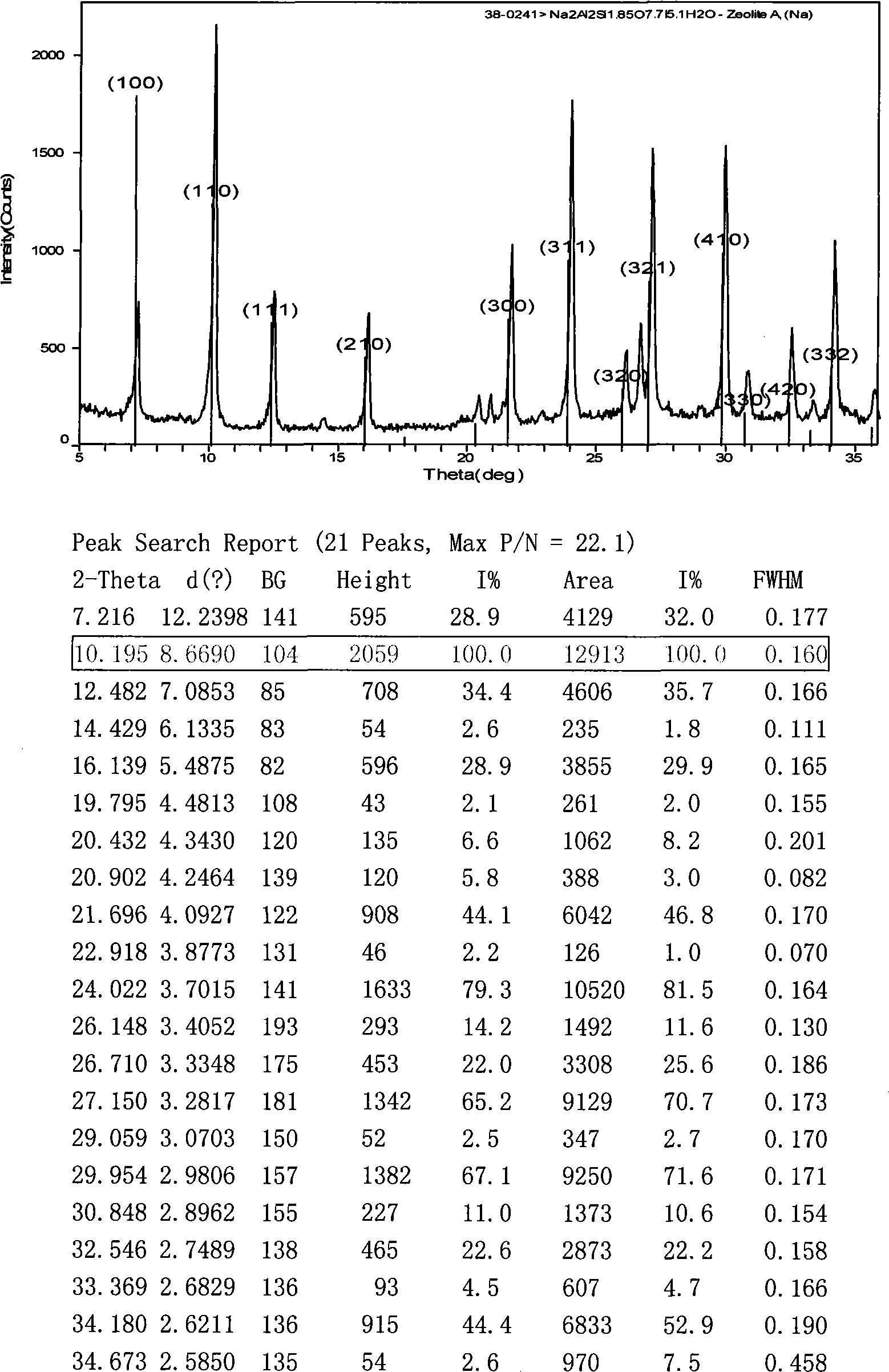

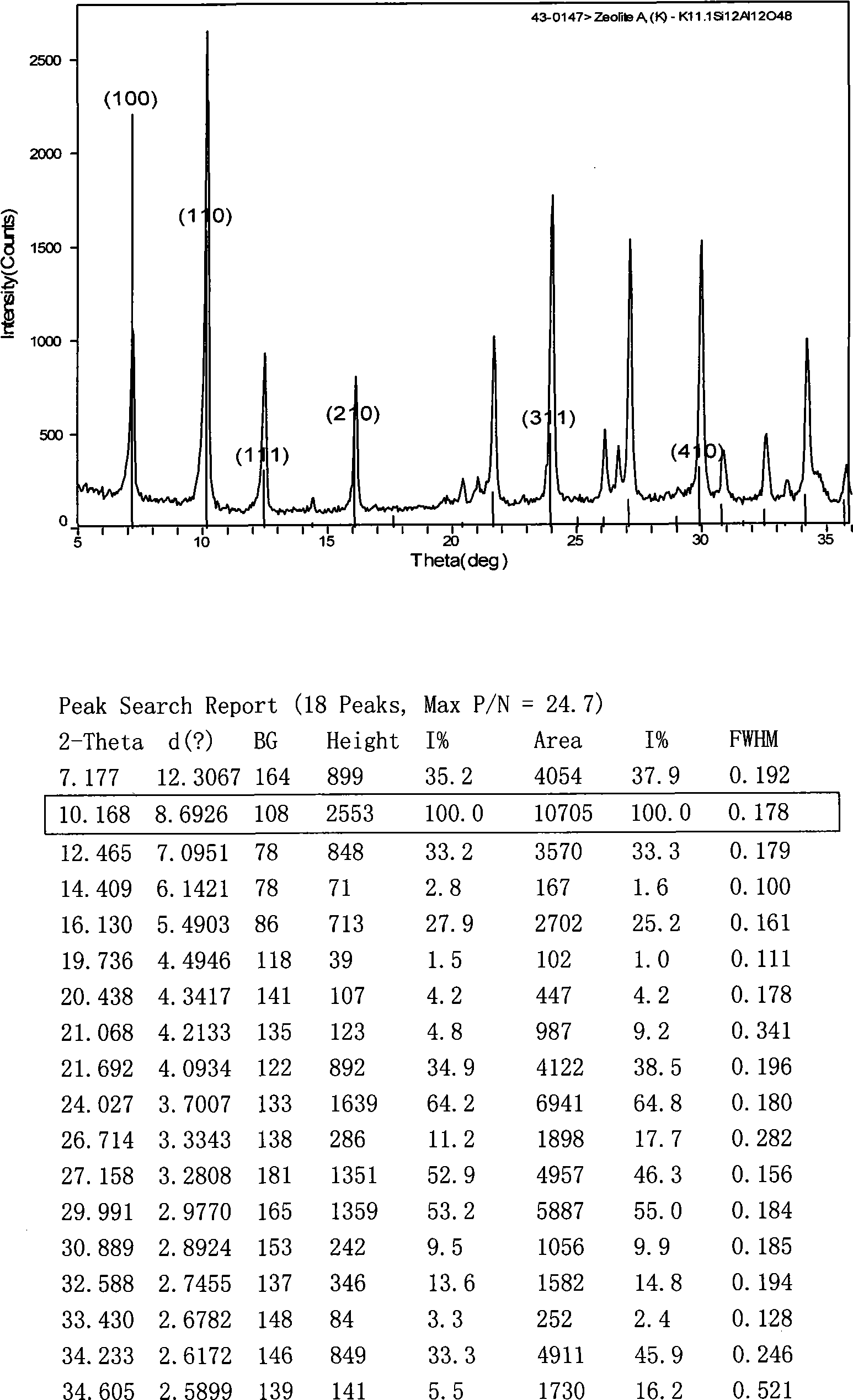

Image

Examples

Embodiment 1

[0035]With 195kgA type molecular sieve (its chemical component and weight percentage are made up of: Al 2 o 3 34.97%, SiO 2 42.82%, Na 2 O 22.21%, 105kg mixed clay (wherein each component weight percent is: attapulgite 65%, bentonite 34%), mixes with 47kg water, in mixing process, adds 16kg chemical modification agent to carry out its structure Modification and modulation, the chemical modification and modulation agent is compounded with the following components by weight percentage: 25% NaOH, 68.8% silica sol, 6.2% aluminum sol, the above-mentioned uniformly mixed mixture is molded and granulated, and finally activated by roasting at 450-550 °C 2 ~6h, after testing the water content is ≤15%, packaged and put into the warehouse, and then made into color: light yellow, white, earthy red, appearance: spherical shape with various diameters from 0.1 to 10mm or strip shape with various diameters from 0.6 to 6mm Desiccant, the indicators tested are as follows:

[0036] Static wa...

Embodiment 2~8

[0042] Embodiment 2~8 preparation method is identical with embodiment 1, and concrete raw material formula sees table 2

[0043] Table 2: Desiccant formulations of Examples 1-8

[0044]

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com