Sulfurized gallium and barium monocrystal as well as growing method and infrared nonlinear optical device thereof

A nonlinear optics, single crystal technology, applied in nonlinear optics, single crystal growth, crystal growth and other directions, can solve the problem of non-linear optical performance test of barium gallium sulfide single crystal, no single crystal of barium gallium sulfide. Single crystal and other problems, to achieve the effect of high hardness, good mechanical properties, not easy to break and deliquescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

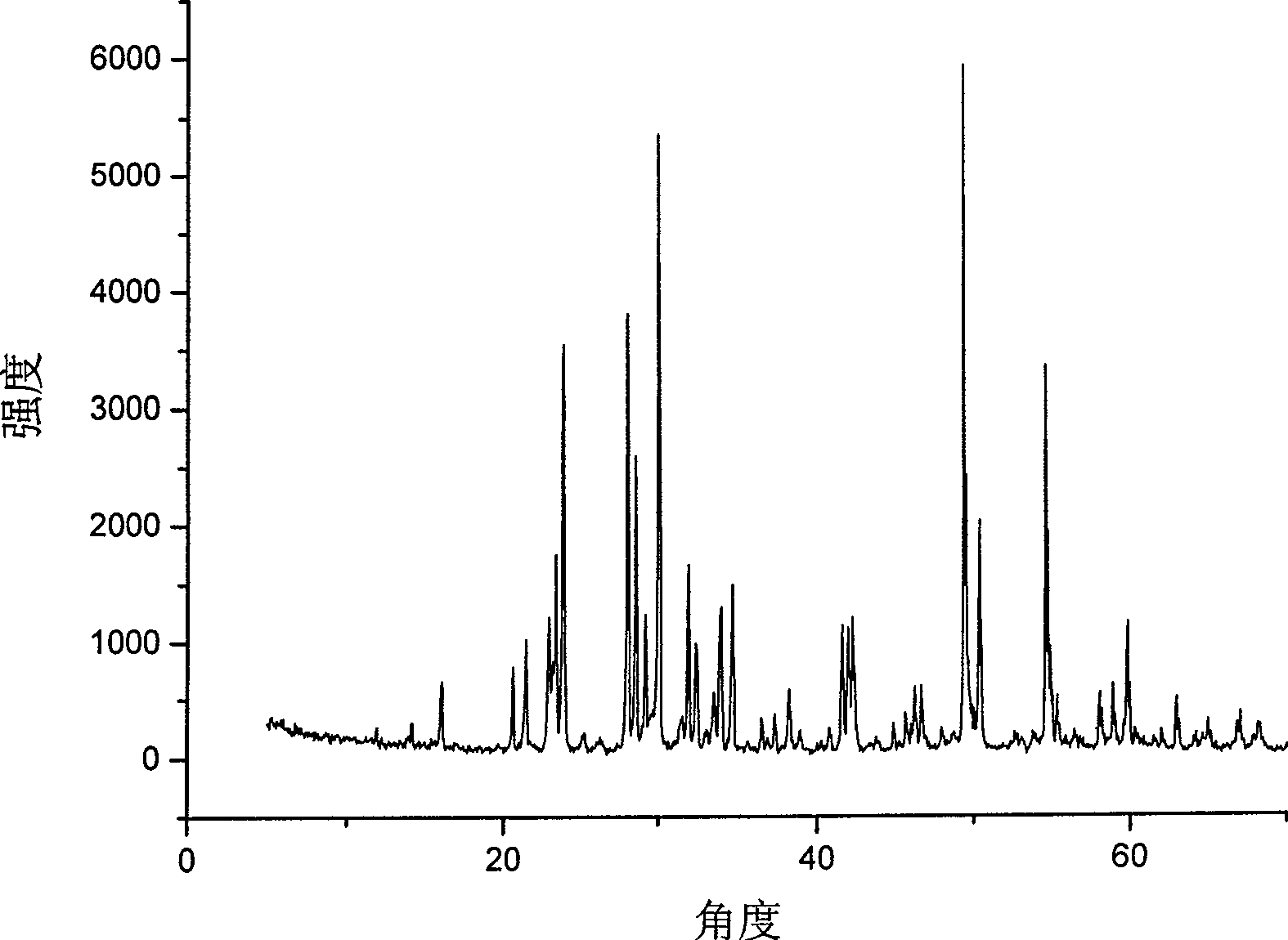

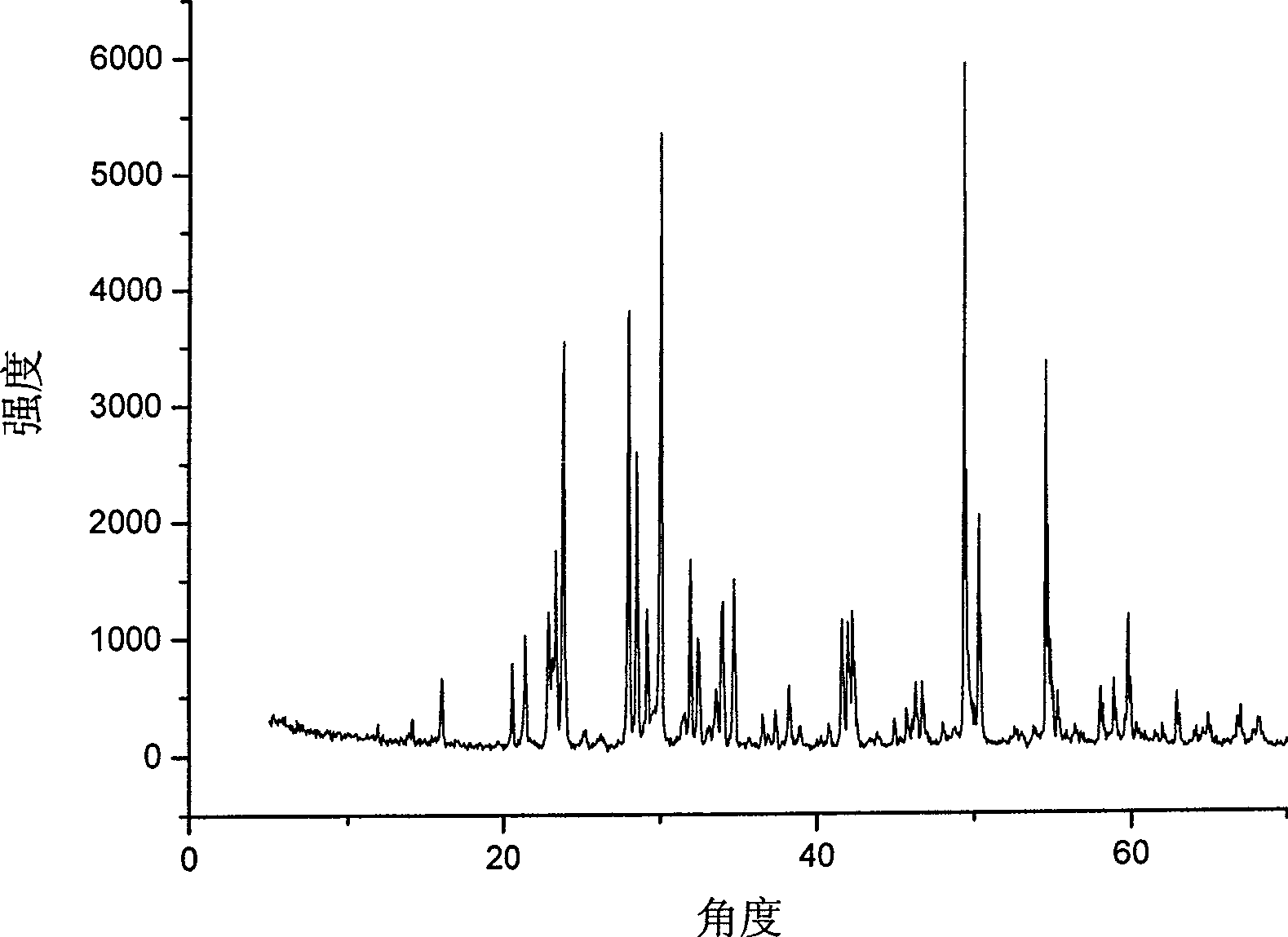

[0022] Synthesis of compound BaGa by high temperature solid phase reaction 4 S 7

[0023] Raw material used: BaS 0.8470g (0.005mol)

[0024] Ga 1.3945g (0.02mol)

[0025] S 0.9620g (0.03mol)

[0026] The chemical reaction equation is:

[0027] BaS+4Ga+6S=BaGa 4 S 7

[0028] The specific operation steps are as follows: After weighing the above-mentioned raw materials according to the above-mentioned dosage, put them in a mortar and mix them evenly and carefully grind them, then put them into a graphite crucible of Φ12×40mm, press them tightly with a medicine spoon, and put them in quartz In the ampoule, after 4-6 hours of vacuuming, when the internal pressure of the quartz ampoule is about 0.1Pa, seal the tube with a hydrogen-oxygen flame and place it in a muffle furnace to slowly raise the temperature to 300°C and heat at a constant temperature for 5 hours, and then to 500 Heat at a constant temperature for 5 hours, then heat to 700°C and heat at a constant tem...

Embodiment 2

[0029] Example 2 Synthesis of compound BaGa by high temperature solid phase reaction 4 S 7

[0030] Raw material used: BaS 0.8470g (0.005mol)

[0031] Ga 2 S 3 2.3564g (0.01mol)

[0032]The chemical reaction equation is:

[0033] BaS+2 Ga 2 S 3 =BaGa 4 S 7

[0034] The specific operation steps are as follows: After weighing the above-mentioned raw materials according to the above-mentioned dosage, put them in a mortar and mix them evenly and carefully grind them, then put them into a Φ12×40mm graphite crucible, press them tightly with a medicine spoon and put them in the quartz In the ampoule, after 4-6 hours of vacuuming, when the internal pressure of the quartz ampoule is about 0.1Pa, seal the tube with a hydrogen-oxygen flame and place it in a muffle furnace to slowly raise the temperature to 700°C and heat at a constant temperature for 20 hours, and then heat to 900 Sinter at a constant temperature for 48 hours at ℃, take out the crucible after cooling, and the sam...

Embodiment 3

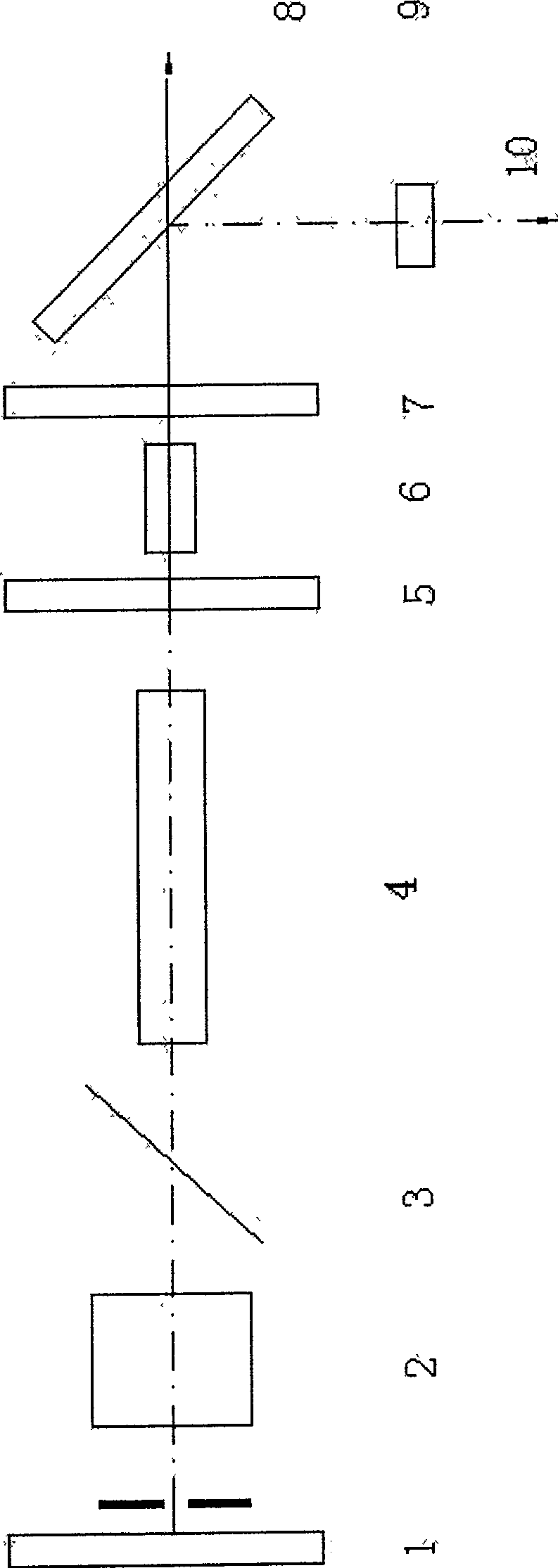

[0035] Example 3 Using molten salt method to grow crystal BaGa 4 S 7

[0036] The crystal growth device is a self-made resistance wire heating furnace, and the temperature control equipment is a 908PHK20 programmable automatic temperature controller.

[0037] Raw material used: BaS 0.8470g (0.005mol)

[0038] Ga 1.3945g (0.02mol)

[0039] S 0.9620g (0.03mol)

[0040] The specific operation steps are as follows: After weighing the above-mentioned raw materials according to the above-mentioned dosage, mix them evenly, then put them into a graphite crucible of Φ12×60mm, press them tightly with a medicine spoon and cover them, and put them in a quartz ampoule for 4-6 hours. After vacuuming, when the internal pressure of the quartz ampoule is about 0.1Pa, seal the tube with a hydrogen-oxygen flame and place it in a growth furnace to slowly raise the temperature to 300°C and heat it at a constant temperature for 5 hours, then to 500°C and heat it at a constant tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com