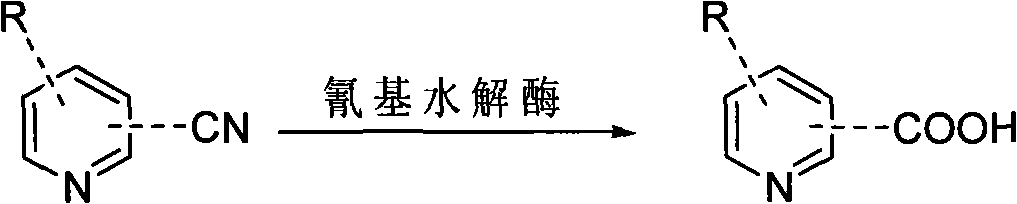

Method for producing nicotinic acid and derivative by catalysis of enzyme

A technology of derivatives and nicotinic acid, which is applied in the field of nicotinic acid prepared by hydrolyzing nicotinic acid with cyanohydrolase, can solve the problems of low yield, easy corrosion of equipment, complicated process, etc., and achieve convenient purification, low equipment requirements, and three wastes discharge low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

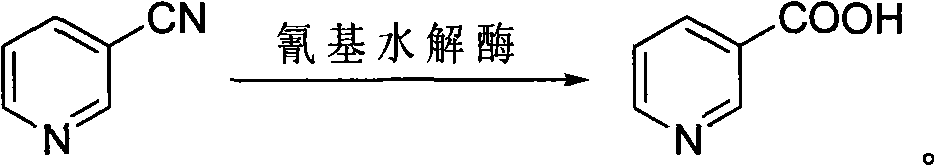

[0023] It is suitable for the screening of 3-cyanopyridine cyanohydrolase.

[0024] The substrate (3-cyanopyridine) was formulated into a 10 g / L dimethyl sulfoxide solution. A total of 40 cyanohydrolase enzymes NIT101 to NIT140 were dissolved in phosphate buffer to prepare a solution with a concentration of 10g / L, the pH of the buffer was 8.0, and the concentration of buffer salt was 100mmol / L.

[0025] Take 40 parts of the substrate solution and place them in a parallel reaction vessel, each 20 μL, and add 160 μL of phosphate buffer to each substrate solution, the pH of the buffer is 8.0, and the buffer salt concentration is 100 mmol / L. Place the parallel reaction container on a shaker and shake it evenly, then add 20 μL of NIT101~NIT140 enzyme solution separately and mark them. Shake in a shaker overnight at room temperature. Then 10 μL of each sample was sampled, and 10 μL of acetonitrile was added to quench the reaction, and the reaction was detected by HPLC and LC-MS. The res...

Embodiment 2

[0028] Dissolve 10 mg of 3-cyanopyridine in 1 mL of dimethyl sulfoxide, add 9 mL of phosphate buffer solution with a pH of 5.5 and a concentration of 100 mmol / L, mix well, add 10 mg of cyanohydrolase NIT104, and stir slowly at room temperature overnight The conversion rate of 3-cyanopyridine was determined to be 100% by HPLC and LC-MS. The water and dimethyl sulfoxide were distilled off under reduced pressure, and the remaining solid was added with 1 mL of ethanol, stirred for 1 hour, filtered to remove the buffer salt, the filtrate was evaporated to dry the ethanol, and recrystallized with water to obtain 8 mg of niacin.

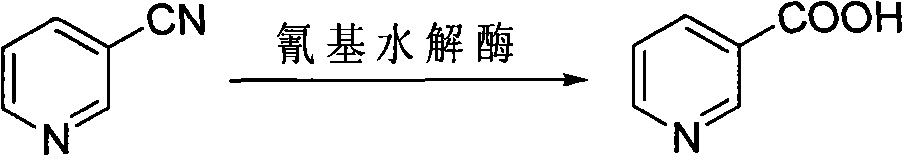

Embodiment 3

[0030] Dissolve 10 mg of 3-cyanopyridine in 1 mL of acetone, add 8 mL of a phosphate buffer with a pH of 7.0 and a concentration of 10 mmol / L, and mix them. Weigh 1 mg of cyanohydrolase NIT129 and dissolve it in 1 mL of the above-mentioned phosphate buffer, add this enzyme solution to the above-mentioned reaction solution, and react at 35°C for 16h. The conversion rate of 3-cyanopyridine was determined to be 100% by HPLC and LC-MS. The solvent was evaporated under reduced pressure, and 1 mL of ethanol was added to the remaining solid, stirred for 1 hour, filtered to remove inorganic salts, and the filtrate was evaporated to dry ethanol and recrystallized with water to obtain 8 mg of niacin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com