Method and apparatus of blast furnace slag quench and heat recovery

A waste heat recovery and blast furnace slag technology, which is applied in the direction of recycling technology and process efficiency improvement, can solve the problems of increasing the flow rate of cooling medium, low quality of recovered heat, contradiction between cooling speed and heat recovery effect, etc., and achieve rapid cooling , Simple structure, easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

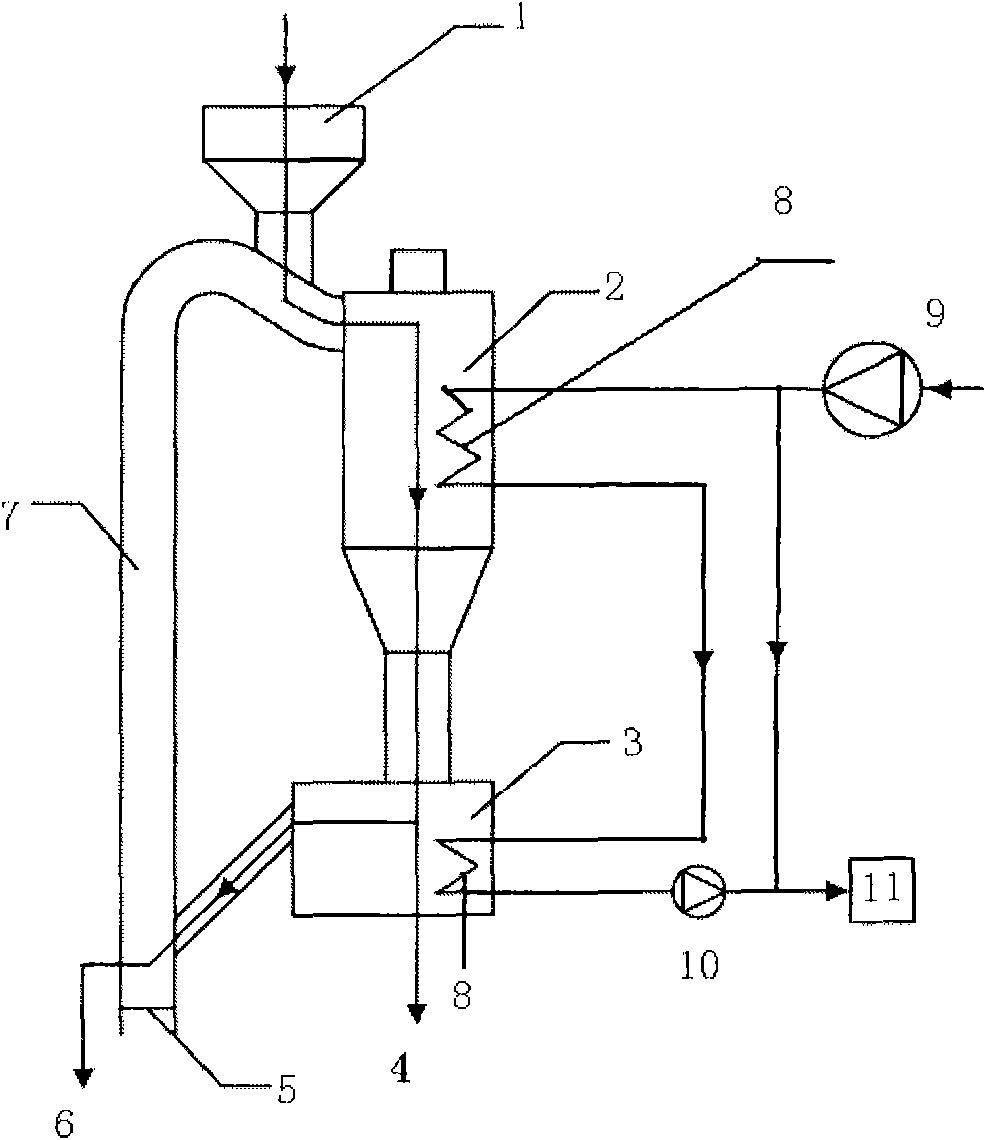

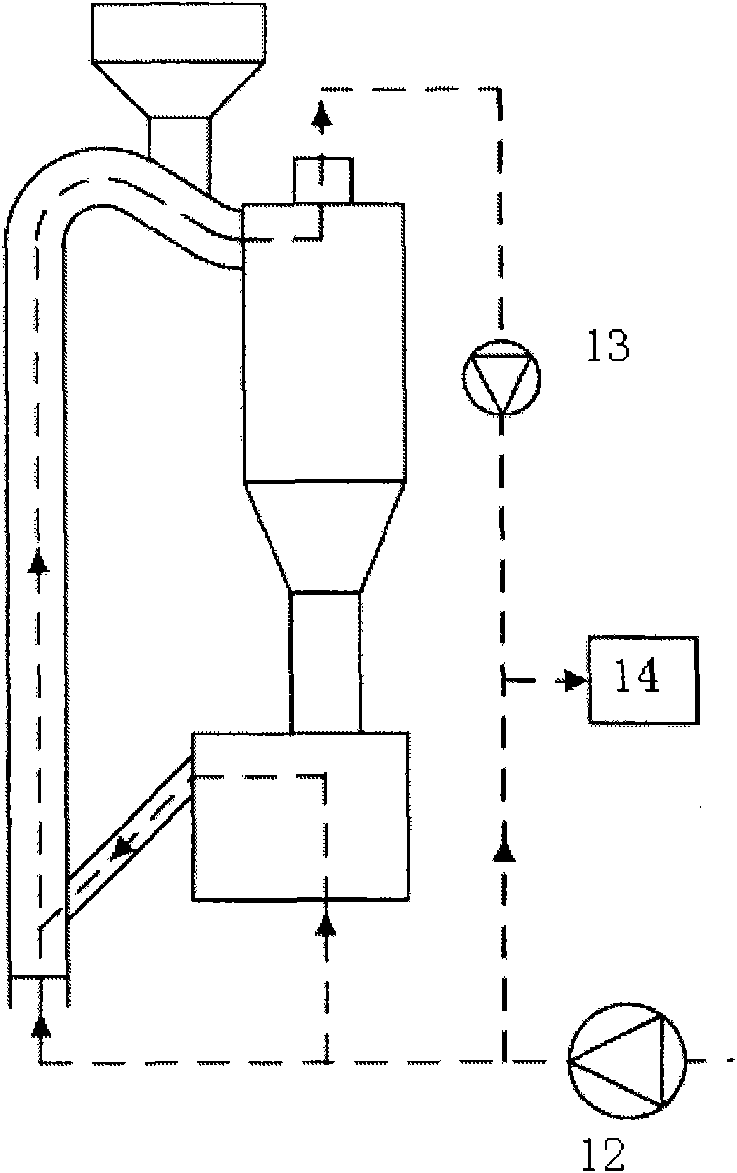

[0016] A device for rapid cooling and waste heat recovery of blast furnace slag, figure 1 For the working system and the blast furnace slag and cooling water circulation loop, the circulating fluidized bed is used to quench the blast furnace slag and recover the waste heat. The pipe connecting the riser to the separator is inclined to the direction of the separator 2 at an angle of 60° to the separator. The inclination angle is used to avoid Blast furnace slag accumulates at the slag inlet, the blast furnace slag inlet 1 is installed on the pipe connecting the riser 7 to the separator, the storage tank 3 is set under the separator 2, the storage tank 3 is set with the coarse slag discharge port 4, and the storage tank 3 Connected to the riser pipe 7, an air distribution plate 5 and a fine slag discharge port 6 are arranged at the lower end of the riser pipe 7, and a water wall 8 is arranged around the separator 2 and the storage tank 3.

[0017] The cooling water in the water wal...

Embodiment 2

[0020] The device of Example 1 is used to rapidly cool blast furnace slag and recover waste heat. The method steps are as follows. After the blast furnace slag is discharged from the blast furnace, it enters the circulating fluidized bed through the blast furnace slag inlet 1, and the fan 12 is provided by the air distribution plate of the riser 7 The fluidizing air blows the blast furnace slag into the separator 2 to achieve gas-solid separation and then enters the storage tank 3. The water-cooled wall 8 arranged outside the separator 2 works together with the fluidizing air to quickly cool the blast furnace slag After granulation, the granulated slag enters the storage tank 3. The fluidizing air provided by the fan 12 passing under the storage tank 3 makes the blast furnace slag form a bubbling bed in the storage tank 3. The water-cooled wall 8 arranged outside the storage tank 3 further cools the blast furnace slag. On the other hand, the fluidizing air stratifies the blast fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com