Conducting film and manufacturing method thereof, electronic device and manufacturing method thereof

A manufacturing method and technology of electronic devices, applied in the direction of cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, chemical instruments and methods, etc., can solve the problem of destroying single-walled carbon nanotube films, substrate restrictions, inapplicability and other problems, to achieve the effects of good conductivity, improved dispersion, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

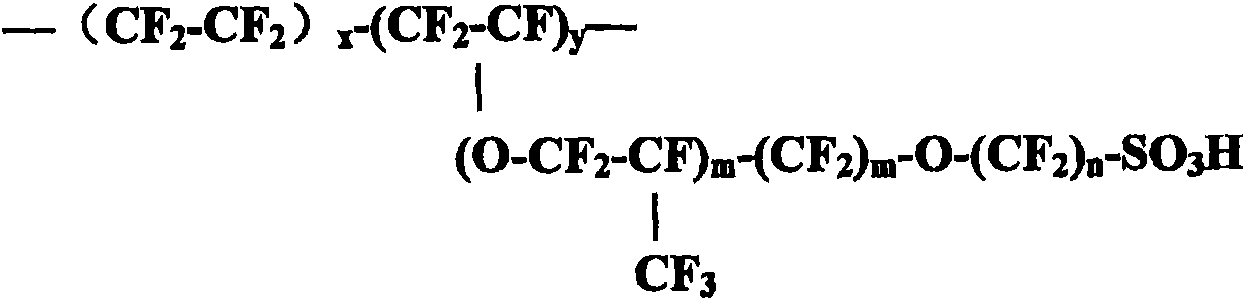

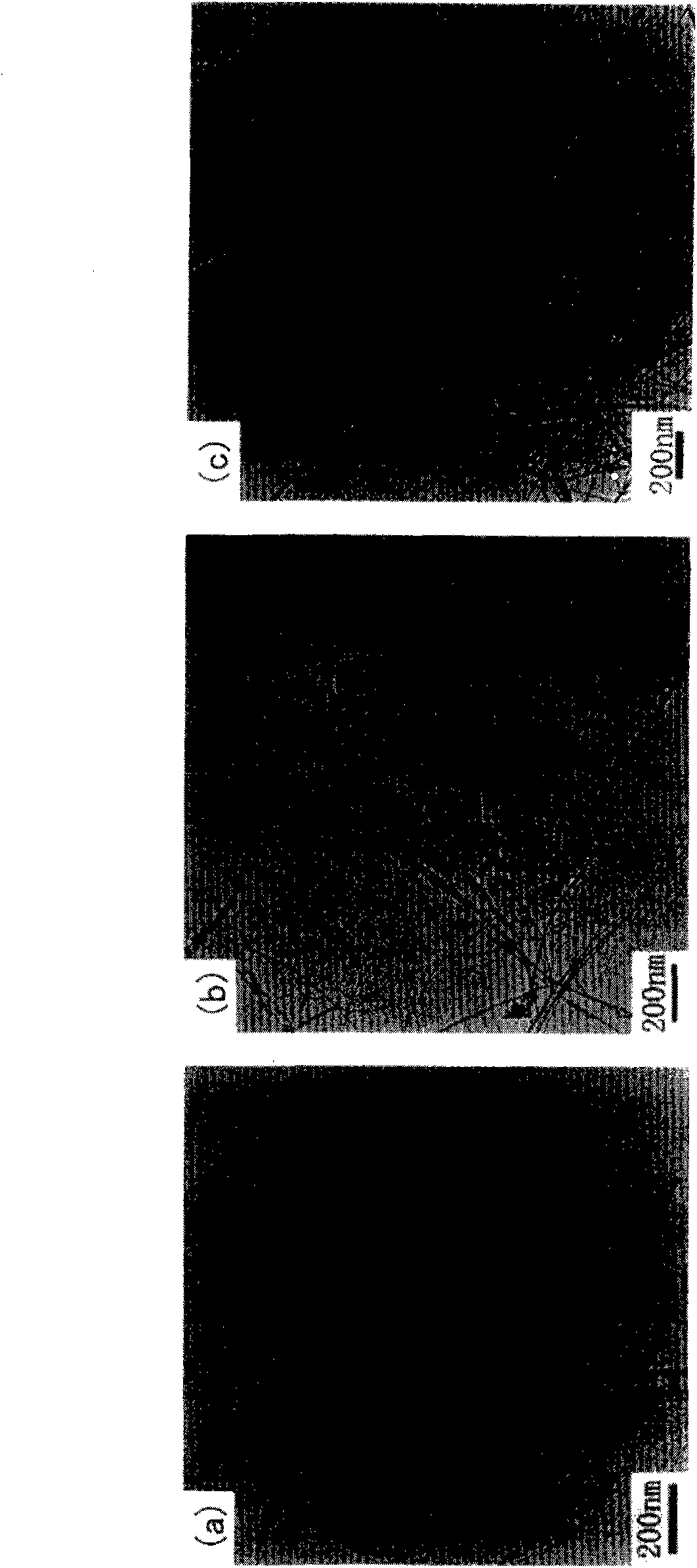

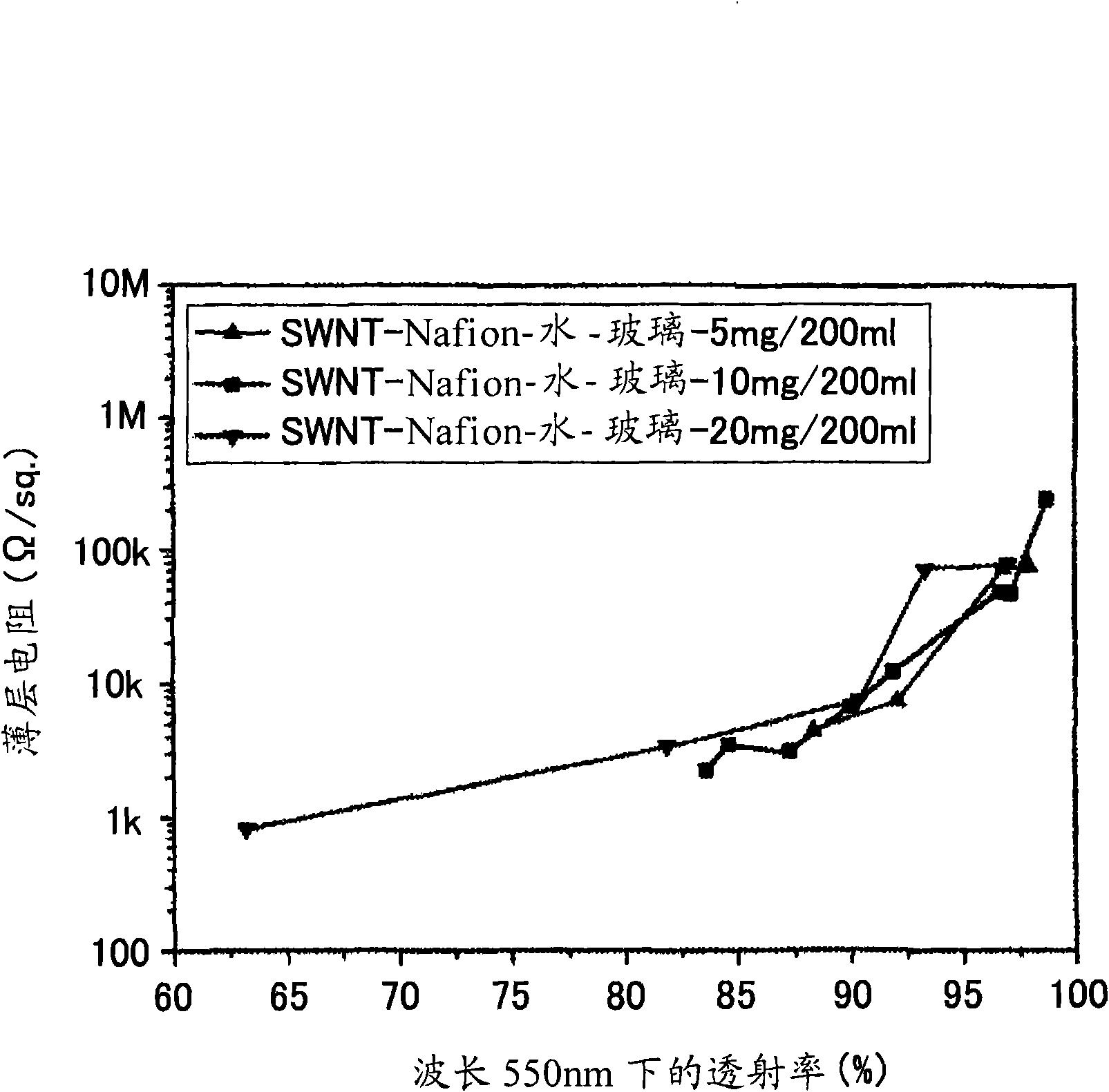

[0069] In order to form a transparent conductive film made of single-walled carbon nanotubes on glass substrates and PET substrates, a solution of dissolving Nafion in water or ethanol (hereinafter referred to as a Nafion-water solution for dissolving Nafion in water, will dissolve Nafion Single-walled carbon nanotubes were dispersed in a solution of ethanol (called Nafion-ethanol solution), and this solution was used to form a transparent conductive film made of single-walled carbon nanotubes by a vacuum filtration method. Detailed description will be given below.

[0070] As the single-walled carbon nanotube, a single-walled carbon nanotube obtained from the Chengdu Organic Institute (Chinese Academy of Sciences) was used. The single-walled carbon nanotubes are based on methane (CH 4 ) as a raw material, CoMo (cobalt molybdenum) as a catalyst, synthesized by chemical vapor deposition (CVD) at 1000 ° C. The length of the single-wall carbon nanotube is about 50 μm, and the p...

Embodiment 2

[0083] In order to form a transparent conductive film made of single-walled carbon nanotubes on glass substrates and PET substrates, in a solution obtained by dissolving Nafion in a mixed solvent of water and ethanol (hereinafter referred to as Nafion-water / ethanol solution) Single-walled carbon nanotubes are dispersed, and the solution is used to form a transparent conductive film made of single-walled carbon nanotubes by a vacuum filtration method. Detailed description will be given below.

[0084] As single-walled carbon nanotubes, Nafion, water and ethanol for diluting and dissolving Nafion, the same substances as in Example 1 were used. In addition, an experiment was performed first, and the same pretreatment (oxidation treatment and reflux treatment) as in Example 1 was performed.

[0085] In order to form a transparent conductive film formed of single-walled carbon nanotubes, a vacuum filtration method is used. First, single-walled carbon nanotubes were dispersed in N...

Embodiment 3

[0091] The conductive film formed on the PET substrate was hot-pressed at 80-150° C. under a pressure of 10 MPa for only 1 minute. exist Figure 18 Among them, the vertical axis represents the sheet resistance value after hot-pressing treatment (R(T)) and the sheet resistance value before hot-pressing treatment (R(T) initial ), the horizontal axis represents the hot-pressing temperature. The softening point of the perfluorosulfonic acid polymer used was 120°C. Even at temperatures below the softening point, the sheet resistance can be reduced by about 10% by hot pressing. If hot pressing is performed at a temperature above the softening point, the sheet resistance value can be reduced by about 20%. When the hot-pressing treatment is performed at a temperature above the softening point of the perfluorosulfonic acid-based polymer used, the improvement of the electrical conductivity is particularly remarkable.

[0092] As described above, since according to this embodiment, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com