Method for improving the yield of lycopene by enhancing growth of Blakeslea trispora

A technology based on brucella and lycopene, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as difficulty in oxygen transfer, high viscosity, and difficulty in industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

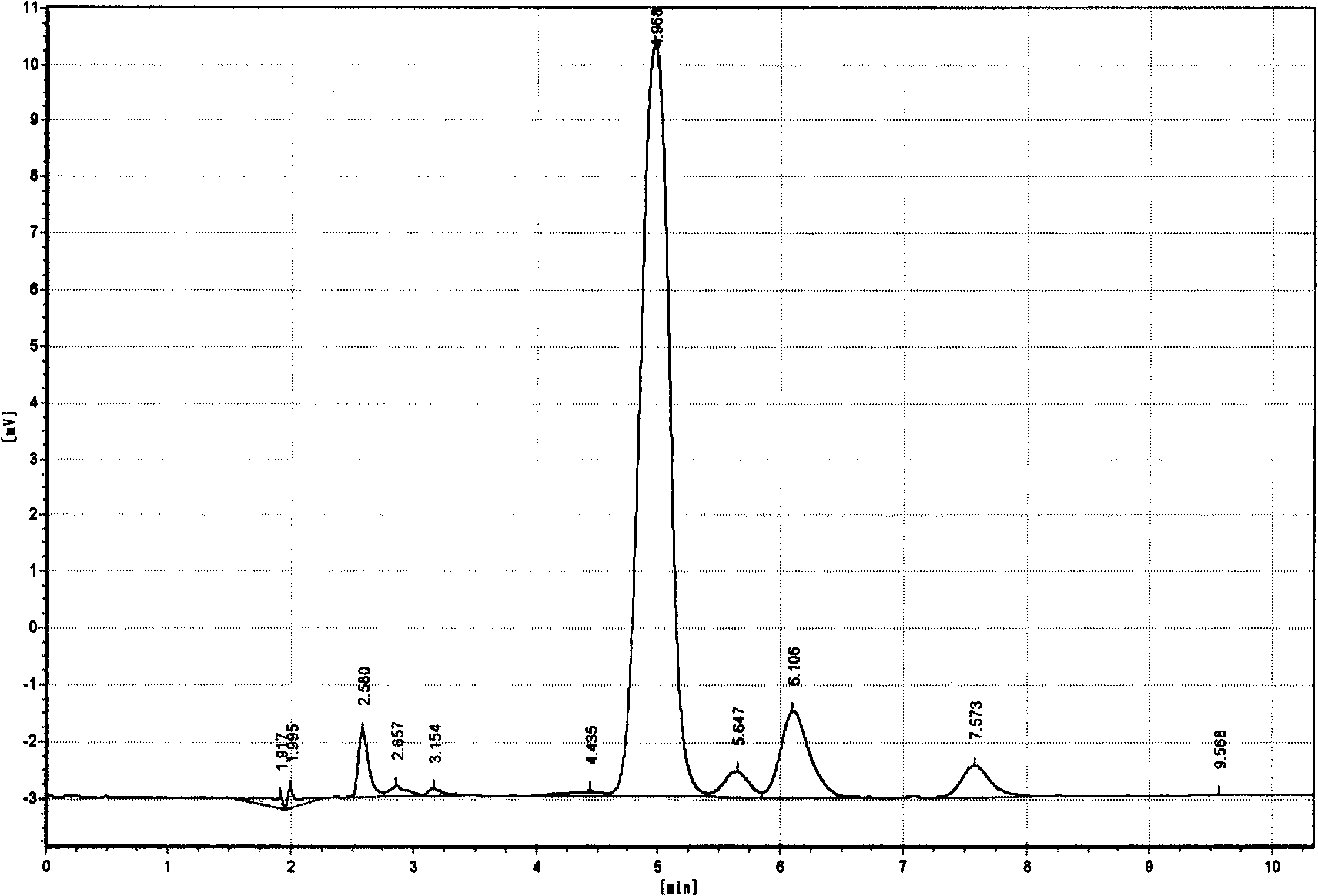

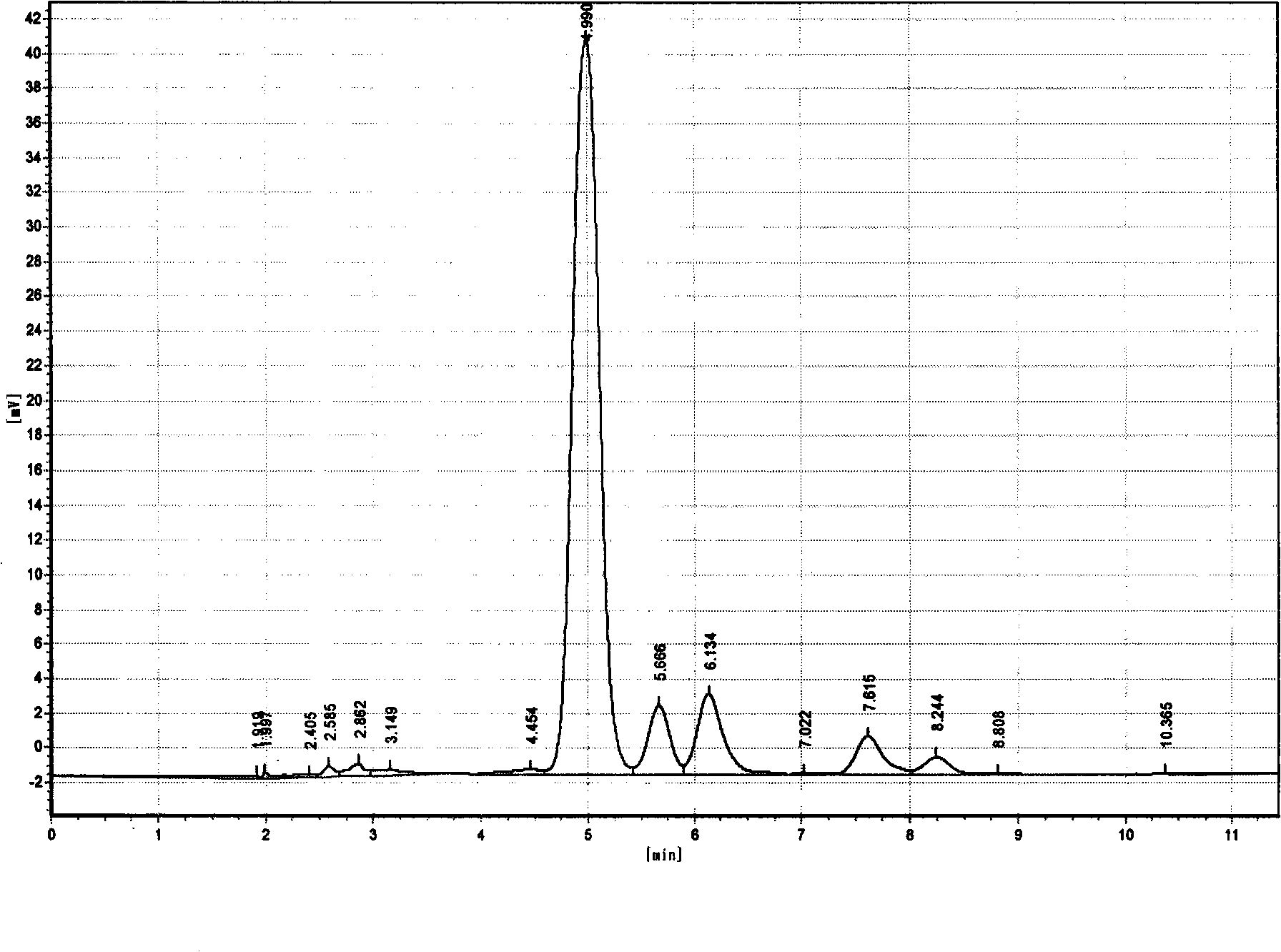

Image

Examples

Embodiment 1

[0025] Embodiment 1: ① plate culture: take 20 g of peeled potatoes, add 200 ml of deionized water to boil, filter the potatoes after cooling, add 2 g of glucose and 2 g of agar to the supernatant, dissolve and subpackage and sterilize at 115 ° C for 30 minutes to prepare PDA Medium. The spore suspensions of B. trispora (+) (-) strains were respectively spread on plates containing PDA medium, and cultured at 28° C. in the dark for 3 days and at 22° C. for 2 days. ② Activated carbon pretreatment: Filter the activated carbon through 200 mesh, 100 mesh, 60 mesh, 16 mesh, and 5 mesh sieves to screen out activated carbon with different particle sizes, soak them in hydrochloric acid with a mass percentage concentration of 0.5% for 2 hours, and suction filter , washed with deionized water until neutral, and dried at 40°C for later use. ③Preparation of seed medium: weigh 40g of starch, 20g of glucose, 50g of corn steep liquor, KH 2 PO 4 1.5g, MgSO 4 0.1g, dissolve in 1 liter of de...

Embodiment 2

[0030] Embodiment 2: ① plate culture: take 20 g of peeled potatoes, add 200 ml of deionized water to boil, filter the potatoes after cooling, add 2 g of glucose and 2 g of agar to the supernatant, dissolve and subpackage for sterilization at 115 ° C for 30 minutes to prepare PDA Medium. The spore suspension of B. trispora (+) (-) strains was spread on a plate containing PDA medium, and cultured at 28° C. in the dark for 3 days and at 22° C. for 2 days. ②Activated carbon pretreatment: Soak 100-mesh activated carbon in hydrochloric acid with a concentration of 0.7% by mass for 2 hours, filter with suction, wash with deionized water until neutral, and dry at 40°C for later use. ③Preparation of seed medium: weigh 40g of starch, 20g of glucose, 50g of corn steep liquor, KH 2 PO 4 1.5g, MgSO 4 0.1g, was dissolved in 1 liter of deionized water, heated and stirred to gelatinize until it became viscous, and the pH value was adjusted to 6.4. Dispense into 250ml Erlenmeyer flasks a...

Embodiment 3

[0035] Embodiment 3: 1. plate culture: take 20 g of peeled potatoes, add 200 ml of deionized water to boil, filter the potatoes after cooling, add 2 g of glucose and 2 g of agar to the supernatant, dissolve and subpackage for sterilization at 115 ° C for 30 minutes to prepare PDA Medium. The spore suspension of B. trispora (+) (-) strains was spread on a plate containing PDA medium, and cultured at 28° C. in the dark for 3 days and at 22° C. for 2 days. ②Activated carbon pretreatment: Soak 100-mesh activated carbon in hydrochloric acid with a concentration of 1.0% by mass for 2 hours, filter with suction, wash with deionized water until neutral, and dry at 40°C for later use. ③Preparation of seed medium: weigh 30g of starch, 15g of glucose, 45g of corn steep liquor, KH 2 PO 4 1.5g, MgSO 4 0.1g, dissolve in 1 liter of deionized water, heat and stir to gelatinize until it becomes viscous, and adjust the pH value to 6.4. Dispense into 250ml Erlenmeyer flasks and sterilize a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com