Method for producing group iii nitride semiconductor layer, group iii nitride semiconductor light-emitting device, and lamp

A technology of nitride semiconductors and light-emitting elements, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve problems such as residual damage to the light-emitting layer, load applied to the semiconductor layer, and defects in the light-emitting layer to prevent internal quantum efficiency. The reduction of the output power, the effect of reducing the leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

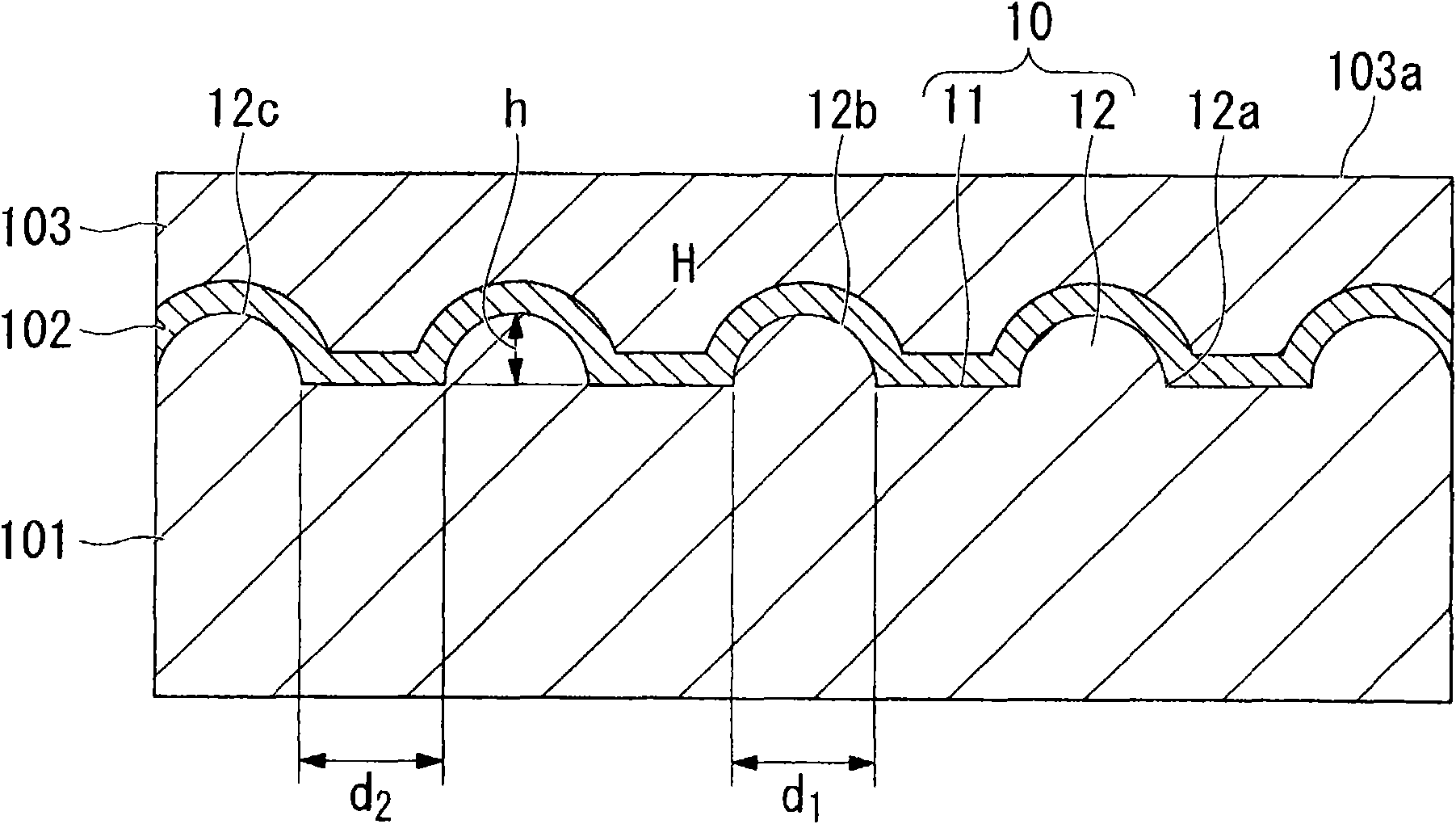

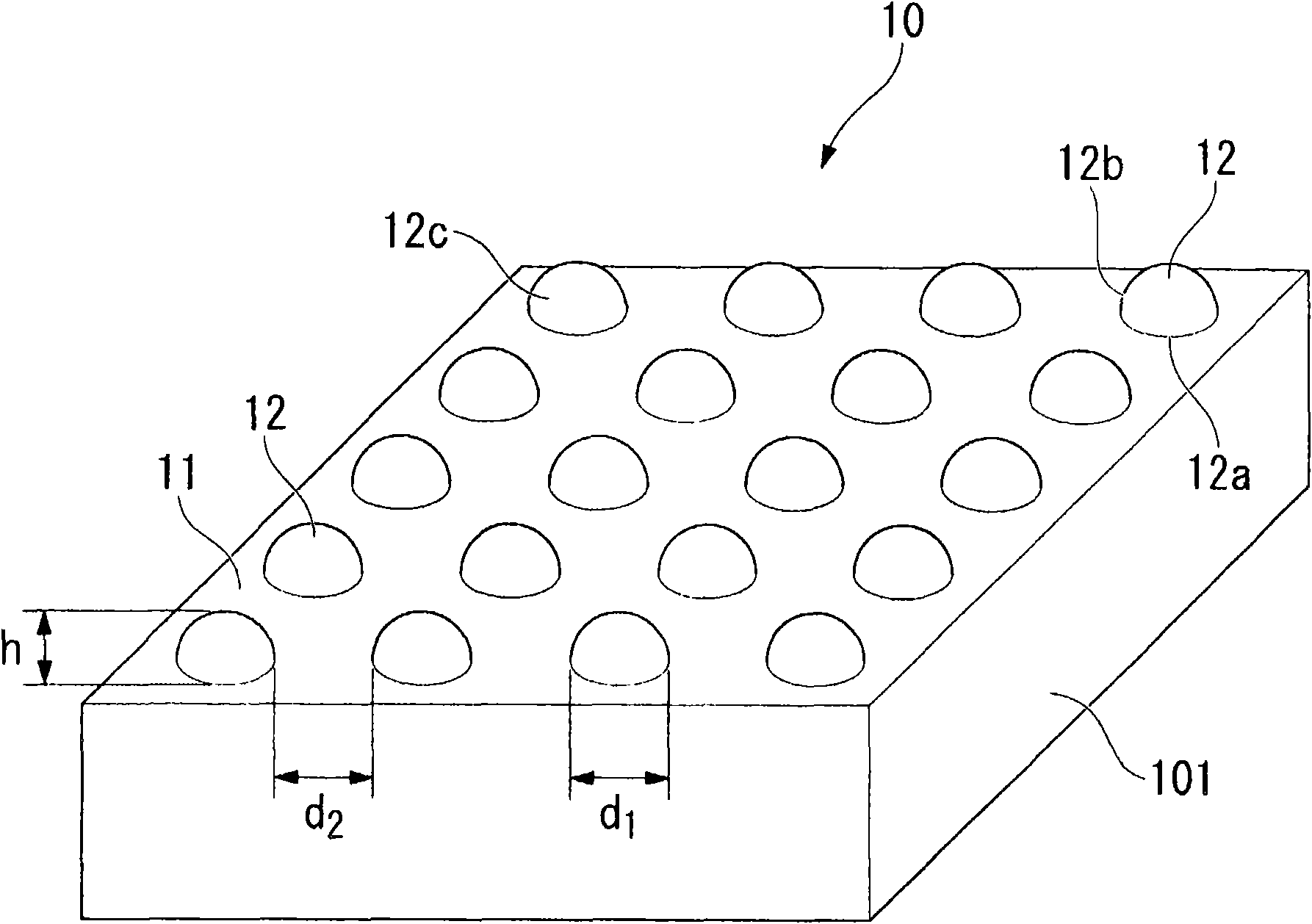

[0157] On the (0001) C plane of the sapphire substrate, the "base width", "height", "base width / 4", "interval between adjacent convex parts", "convex part width" shown in Table 1 are formed as follows. The presence or absence of multiple protrusions on the surface C surface (substrate processing process). That is, a mask was formed on a C-plane sapphire substrate with a diameter of 2 inches by a known photolithography method, and the convex portion was formed by etching the sapphire substrate by a dry etching method. In addition, as an exposure method, the step exposure method using ultraviolet rays was used. Also, using BCl in dry etching 3 with Cl 2 of the gas mixture.

[0158] Table 1

[0159]

[0160] The convex portion of Example 1 obtained in this way has a circular planar shape at the base, and a shape that gradually decreases toward the upper portion, and has a bowl-like (hemispherical) shape with sides curved outward.

Embodiment 2、 comparative example 4

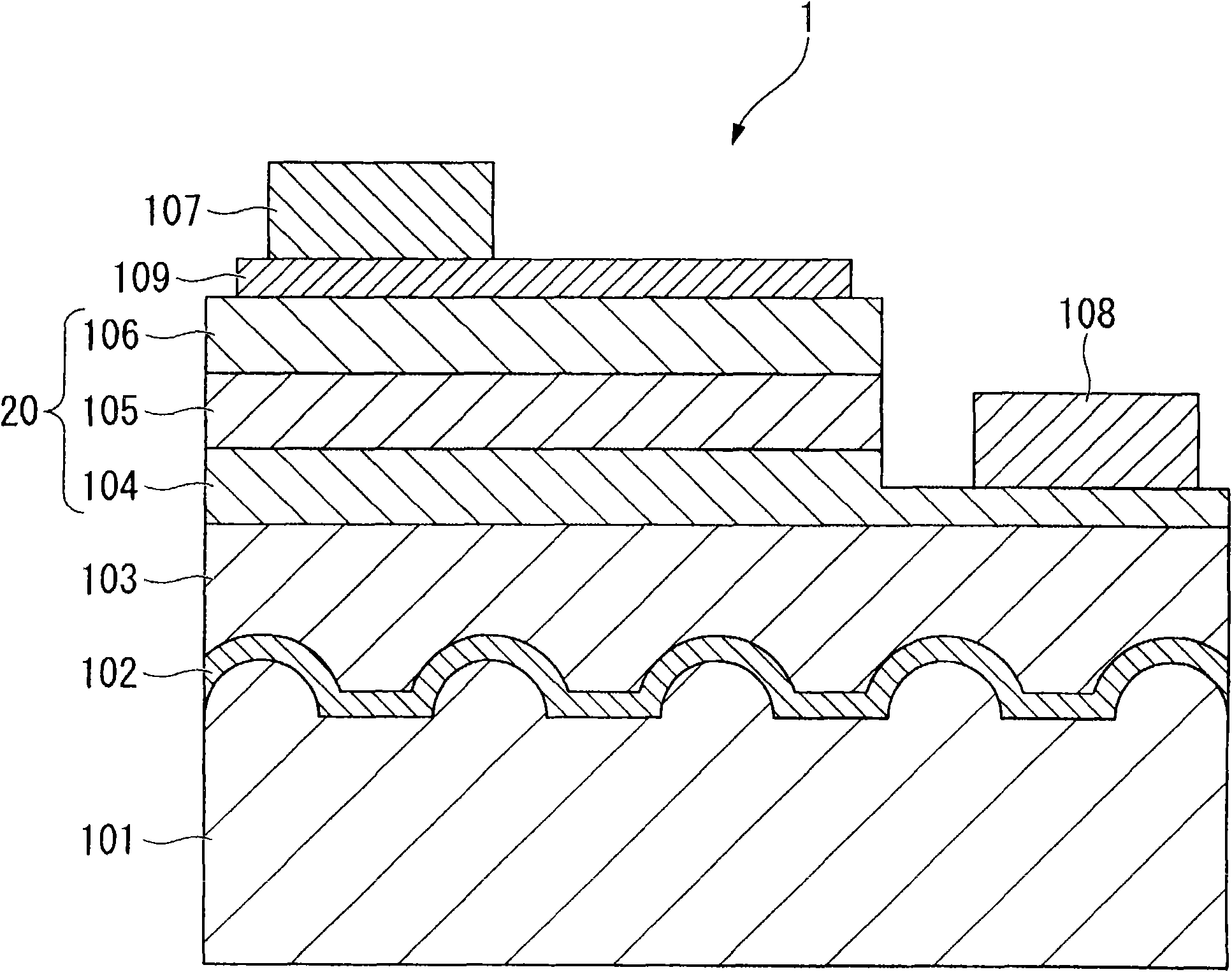

[0179] The n-type layer, the light-emitting layer, and the p-type layer forming the LED structure were stacked on the Group III nitride semiconductor layer prepared by the same method as in Example 1 and Comparative Example 3 by the method described below.

[0180] (n-type layer)

[0181] As the n-type layer, an n-contact layer and an n-cladding layer are formed. First, after growing the group III nitride semiconductor layer by the same method as in Example 1 and Comparative Example 3, the amount of ammonia was adjusted so that the ratio of group V (N) / group III (Ga) was 450, and the group III nitride semiconductor layer A 1 μm non-doped GaN layer is grown on it. Then under the same conditions, using monosilane (SiH 4 ) gas to form an n-contact layer composed of a 2 μm n-type GaN layer.

[0182] The doping amount of Si is 5×10 18 / cm 3 . After the n-contact layer was grown, the TMG valve was closed to stop the supply of TMG into the reaction furnace.

[0183] After the ...

Embodiment 3、 Embodiment 4、 comparative example 5

[0209] Embodiment 3, embodiment 4, comparative example 5, comparative example 6

[0210] In addition to the contents shown in Table 3, "base width", "height", "base width / 4", "interval between adjacent convex parts", and "presence of C surface on the surface of the convex part" were adopted and implemented. A light-emitting device was produced in the same manner as in Example 2 in the same manner as in Example 1 until the Group III nitride semiconductor layer was formed.

[0211] In addition, the convex part of Example 3, Example 4, and Comparative Example 6 has a circular planar shape of the base, a shape that gradually becomes smaller toward the upper part, and a bowl-shaped shape with sides curved outward. In addition, the protrusions of Example 3, Example 4, and Comparative Example 6 are protrusions obtained by changing the height of the protrusions by changing the etching time.

[0212] Then, a current of 20 mA was applied in the forward direction to the obtained light-e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com