Method for preparing stimulating responsive polymer brush

A stimuli-responsive, polymer brush technology, applied in the field of preparation of stimuli-responsive polymer brushes, can solve the problems of difficult large-scale preparation, time-consuming and labor-intensive, restricting the use of polymer brushes, etc., to achieve simple operation, broad application prospects, The effect of high graft density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Substrate treatment

[0020] Boil the silicon substrate in a mixed solution of concentrated sulfuric acid and hydrogen peroxide for 1 hour. The mass ratio of concentrated sulfuric acid and hydrogen peroxide in the mixed solution is 7:3. Then place the substrate in acetone for 30 minutes and rinse it with deionized water. , drying to remove organic matter and impurities on the surface of the substrate.

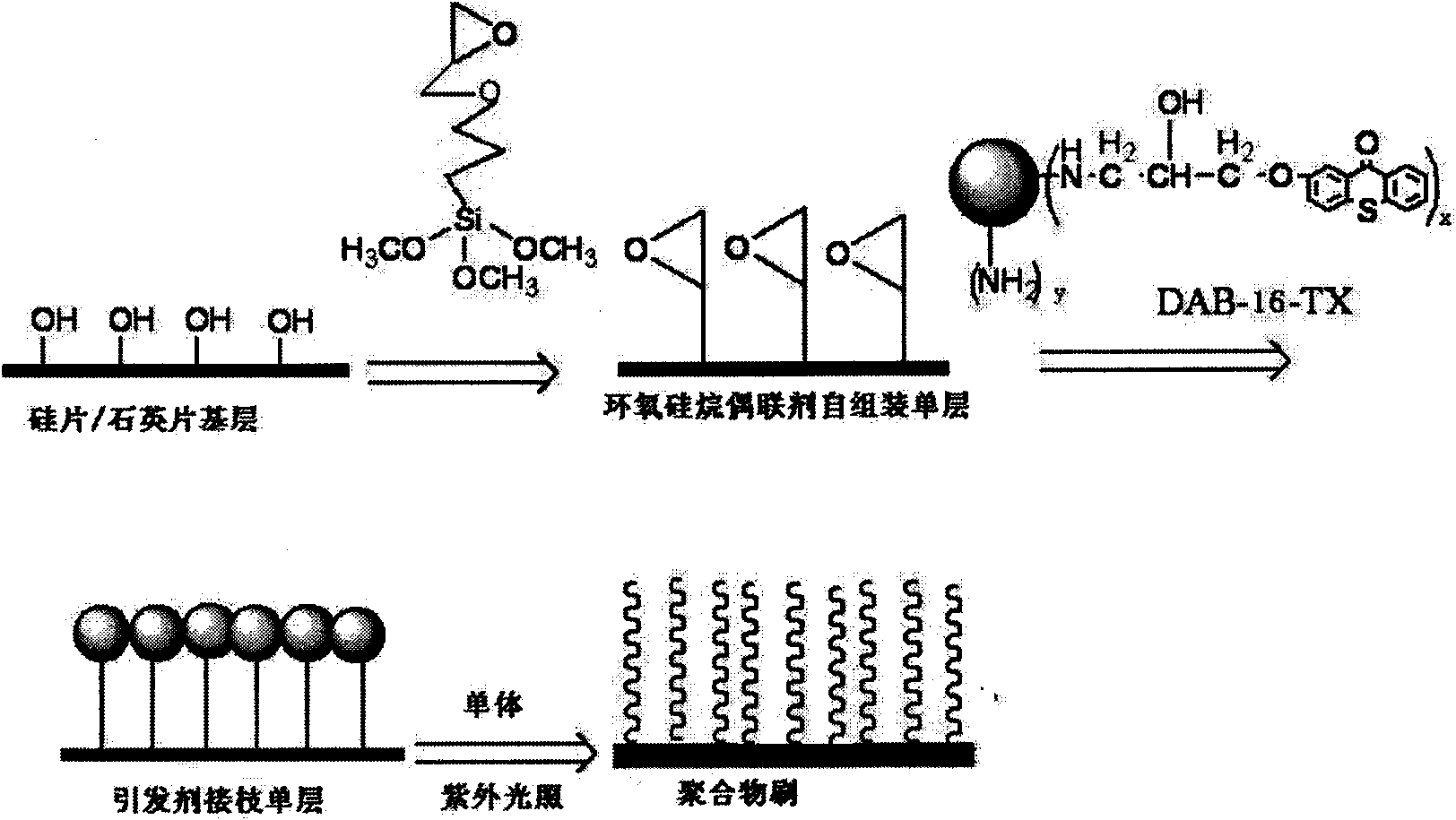

[0021] 2. Self-assembly of epoxy silane coupling agent

[0022] The cleaned and dried substrate was immersed in a 5 mM toluene solution of 3-glycidyl propoxytrimethoxysilane and allowed to stand for 12 hours. Then, the taken-out substrate was ultrasonically cleaned successively in toluene and acetone, and then dried to obtain the self-assembled substrate of epoxy silane coupling agent.

[0023] 3. Initiator DAB-16-TX grafting

[0024] Immerse the self-assembled substrate of the epoxy silane coupling agent in a chloroform solution with a photoinitiator DAB-16-TX con...

Embodiment 2

[0028] 1. Substrate treatment

[0029] Boil the silicon substrate in a mixed solution of concentrated sulfuric acid and hydrogen peroxide for 1.5 hours. The mass ratio of concentrated sulfuric acid to hydrogen peroxide in the mixed solution is 7:3. Then place the substrate in acetone for 20 minutes of ultrasonication. Rinse and dry to remove organic matter and impurities on the surface of the substrate.

[0030] 2. Self-assembly of epoxy silane coupling agent

[0031] The cleaned and dried substrate was immersed in a 5 mM toluene solution of 3-glycidyl propoxytrimethoxysilane and allowed to stand for 12 hours. Then, the taken-out substrate was ultrasonically cleaned successively in toluene and acetone, and then dried to obtain the self-assembled substrate of epoxy silane coupling agent.

[0032] 3. Initiator DAB-16-TX grafting

[0033] Immerse the self-assembled substrate of the epoxy silane coupling agent in a chloroform solution with a photoinitiator DAB-16-TX concentrati...

Embodiment 3

[0038] 1. Substrate treatment

[0039] Boil the silicon substrate in a mixed solution of concentrated sulfuric acid and hydrogen peroxide for 2 hours. The mass ratio of concentrated sulfuric acid and hydrogen peroxide in the mixed solution is 7:3. Then place the substrate in acetone for 10 minutes and rinse it with deionized water. , drying to remove organic matter and impurities on the surface of the substrate.

[0040] 2. Self-assembly of epoxy silane coupling agent

[0041] The cleaned and dried substrate was immersed in a 10 mM toluene solution of 3-glycidyl propoxytrimethoxysilane and allowed to stand for 12 h. Then, the taken-out substrate was ultrasonically cleaned successively in toluene and acetone, and then dried to obtain the self-assembled substrate of epoxy silane coupling agent.

[0042] 3. Initiator DAB-16-TX grafting

[0043] Immerse the self-assembled substrate of the epoxy silane coupling agent in a chloroform solution with a photoinitiator DAB-16-TX concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com