High-temperature stable medium material for multilayer ceramic capacitors and preparation method thereof

A technology of capacitor dielectric and multilayer ceramics, which is applied in the direction of fixed capacitor dielectric, laminated capacitor, fixed capacitor parts, etc., can solve the problem of reducing the dielectric properties of dielectric materials, and achieve wide temperature stability range and high dielectric strength Constant, the effect of excellent temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Ingredients basis: (1-x)BaTiO 3 -xBiScO 3 +a(CaF 2 +4LiF), x=0.05, a is 1 mol% of the molar number of the main component.

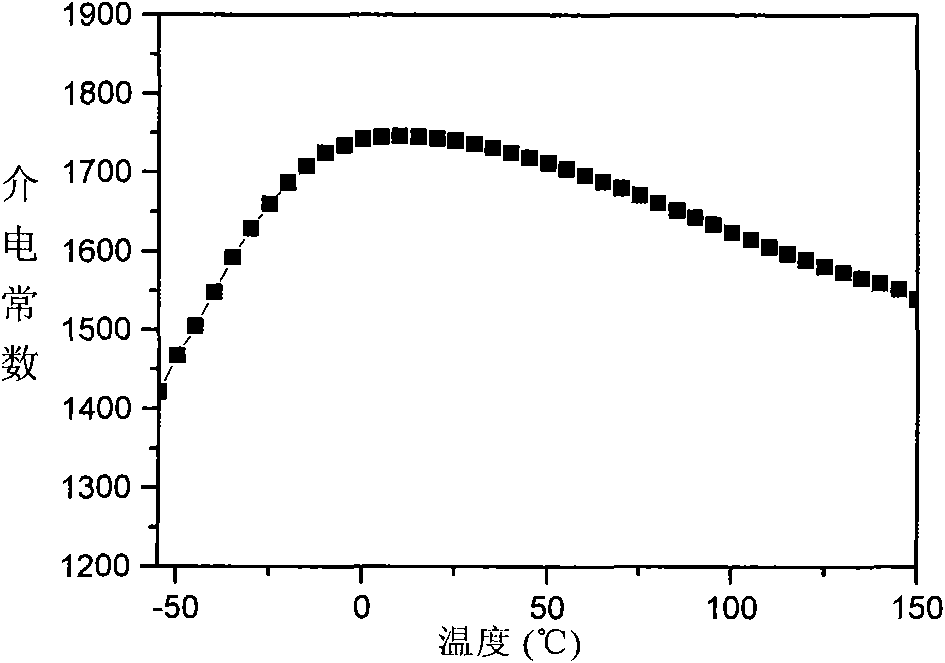

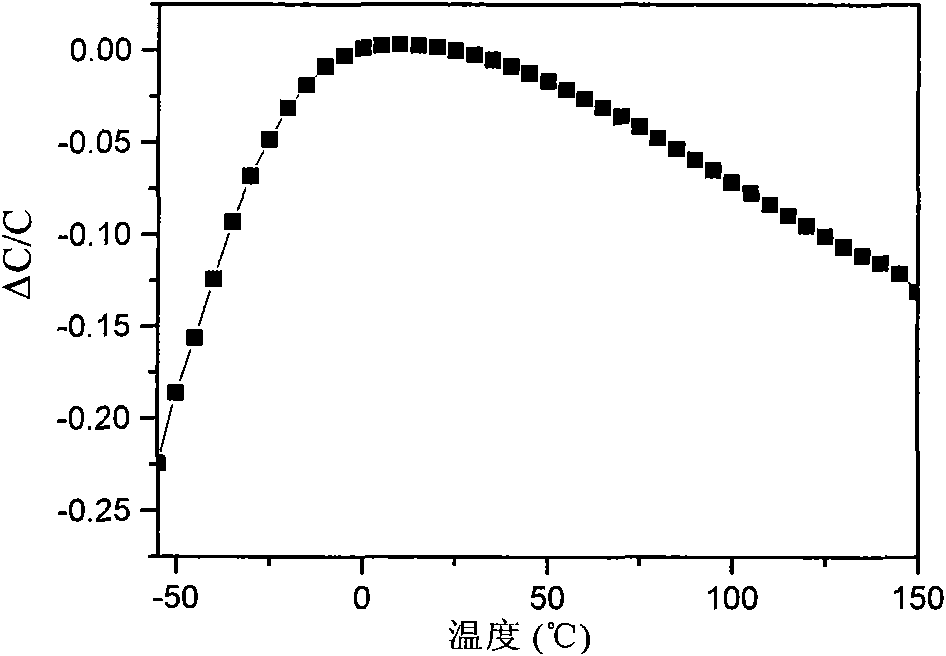

[0028] The materials were mixed and ball milled according to the above preparation method, then dried, sieved, granulated into uniform granules with a concentration of 0.25wt% PVA as a binder, and pressed under a pressure of 200MPa to make discs with a diameter of 12mm with a thickness of 1mm. The discs were calcined at 650 °C to remove the PVA binder, and then 2 o 3 In a sealed corundum crucible, sinter at a temperature of 1200°C, the sintering time is 2 hours, and the heating rate is 5°C / min. The fired ceramic discs were surface polished, silver-fired, and their dielectric properties were measured. The dielectric properties of the obtained ceramic samples are shown in Table 1. figure 1Be the characteristic curve that the dielectric constant of embodiment 1 sample changes with temperature; figure 2 It is the curve of the rate of change of...

Embodiment 2

[0032] Ingredients basis: (1-x)BaTiO 3 -xBiScO 3 +a(CaF 2 +4LiF), x=0.10, a is 3 mol% of the molar number of the main component.

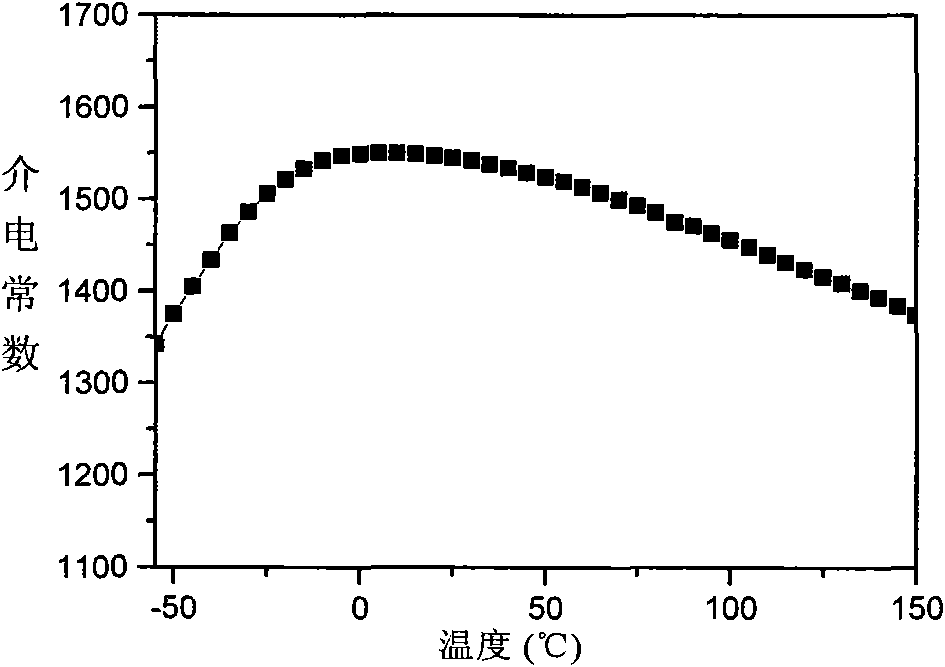

[0033] The materials were mixed and ball milled according to the above-mentioned preparation method, then dried, sieved, granulated into uniform particles with a concentration of 0.25wt% PVA as a binder, and pressed under a pressure of 200MPa to make discs with a diameter of 12mm with a thickness of 1mm. The discs were calcined at 650 °C to remove the PVA binder, and then 2 o 3 In a sealed corundum crucible, sinter at a temperature of 1160°C, the sintering time is 2 hours, and the heating rate is 5°C / min. The fired ceramic discs were surface polished, silver-fired, and their dielectric properties were measured. The dielectric properties parameters of the obtained ceramic samples are shown in Table 2. image 3 Be the characteristic curve that the dielectric constant of embodiment 2 sample changes with temperature; Figure 4 It is the curve o...

Embodiment 3

[0036] Ingredients basis: (1-x)BaTiO 3 -xBiScO 3 +a(CaF 2 +4LiF), x=0.10, a is 5 mol% of the molar number of the main component.

[0037] The materials were mixed and ball milled according to the above-mentioned preparation method, then dried, sieved, granulated into uniform particles with a concentration of 0.25wt% PVA as a binder, and pressed under a pressure of 200MPa to make discs with a diameter of 12mm with a thickness of 1mm. The discs were calcined at 650 °C to remove the PVA binder, and then 2 o 3 In a sealed corundum crucible, sinter at a temperature of 1160°C, the sintering time is 2 hours, and the heating rate is 5°C / min. The fired ceramic discs were surface polished, silver-fired, and their dielectric properties were measured. The dielectric performance parameters of the obtained ceramic samples are shown in Table 3. Figure 5 Be the characteristic curve that the dielectric constant of embodiment 3 sample changes with temperature; Figure 6 It is the curve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com