Carbon aerogel composite pair electrode used for dye-sensitized solar cell and preparation method thereof

A technology of solar cells and carbon aerogels, applied in capacitor electrodes, electrical components, photosensitive equipment, etc., can solve the problems of restricting large-scale applications, high cost, unfavorable flexible counter electrodes, etc., and achieve low cost, high conductivity, Solve the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

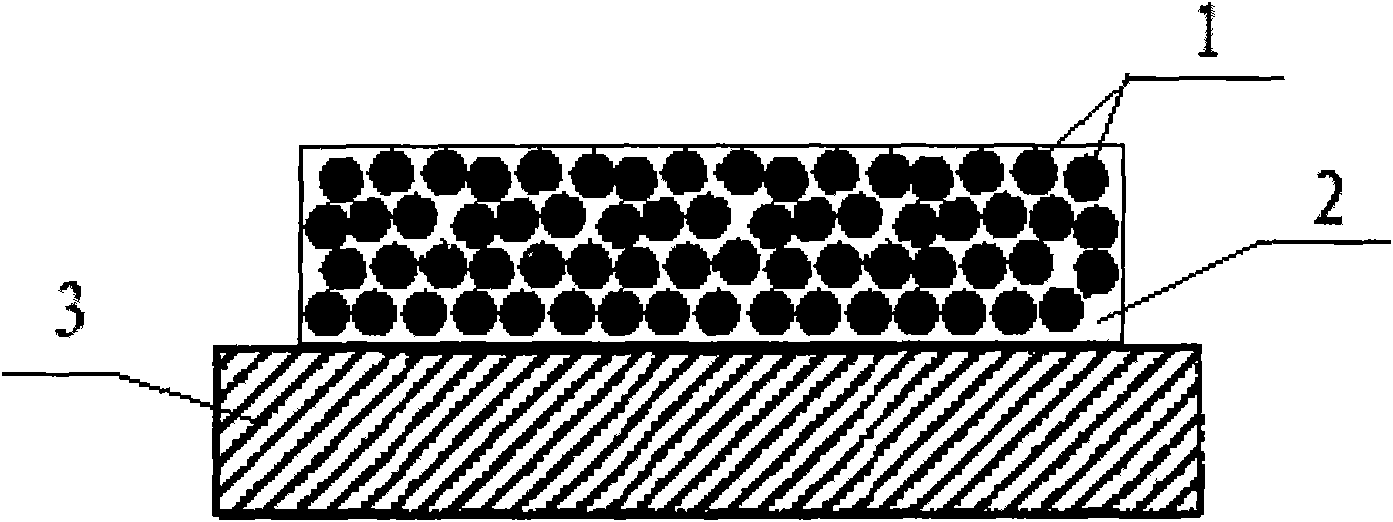

[0018] Example 1: Cut the ITO glass into pieces with a size of 1cm×1.5cm, then use detergent, distilled water, absolute ethanol, and isopropanol to ultrasonically clean it for 15 minutes, and then perform oxygen plasma treatment on it for 5 minutes. , the power is 20 ~ 50W, the main function of the treatment is to reduce the average roughness and peak-valley roughness of the conductive glass surface film, so as to improve its flatness; and to increase the surface energy of the conductive glass and reduce its contact angle , so that the wettability and adsorption performance of the conductive film surface of the conductive glass can be improved. The carbon airgel and polydioxyethylthiophene / polystyrene sulfonic acid aqueous solution (PEDOT:PSS, Bayer, Baytron 4083) were formulated into suspensions with different concentrations (mass percentage concentration between 5% and 40%) ), the prepared suspension is spin-coated on the conductive glass at a rotation speed of 500-3000 rpm ...

Embodiment 2

[0019] Embodiment 2: stainless steel sheet (or nickel sheet) is cut into the sheet of 1cm * 1.5cm size, cleans up with dehydrated alcohol, stand-by; Aqueous acid solution (PEDOT:PSS) is prepared into suspensions of different concentrations (concentrations are between 5% and 40%), and the prepared suspension is spin-coated on the conductive surface at a rotation speed of 500-3000 rpm on a homogenizer. On the glass surface, the spin-coating time was 30s, and after spin-coating, it was baked in an oven at 150° C. for 30 minutes, and a counter electrode with catalytic activity was obtained after drying.

Embodiment 3

[0020] Embodiment 3: stainless steel sheet (or nickel sheet) is cut into the sheet of 1cm * 1.5cm size, cleans up with dehydrated alcohol, stand-by; With mass ratio be the ratio of 9: 1 with polytetrafluoroethylene Mix the aqueous suspension of ethylene (60% by mass fraction), add 5% absolute ethanol, ultrasonicate for 15 minutes, let it mix well, and then apply it evenly on the above-mentioned treated stainless steel sheet with a glass rod. Dry it in a vacuum drying oven at about 45°C for 24-48 hours to make it dry enough. After drying, use a tablet press to press the stainless steel sheet with a pressure of 20MPa to make the material more evenly attached to the sheet and obtain a flexible carbon with catalytic activity. Airgel composite counter electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com