Photoelectric packaging part with cavity and production method thereof

A packaging and optoelectronic technology, applied in electrical components, electric solid-state devices, semiconductor devices, etc., can solve the problems of affecting the packaging yield rate of the whole machine installation qualification rate, affecting the high-frequency performance of the circuit, reducing the material utilization rate, etc. The effect of high packaging yield, high production efficiency and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

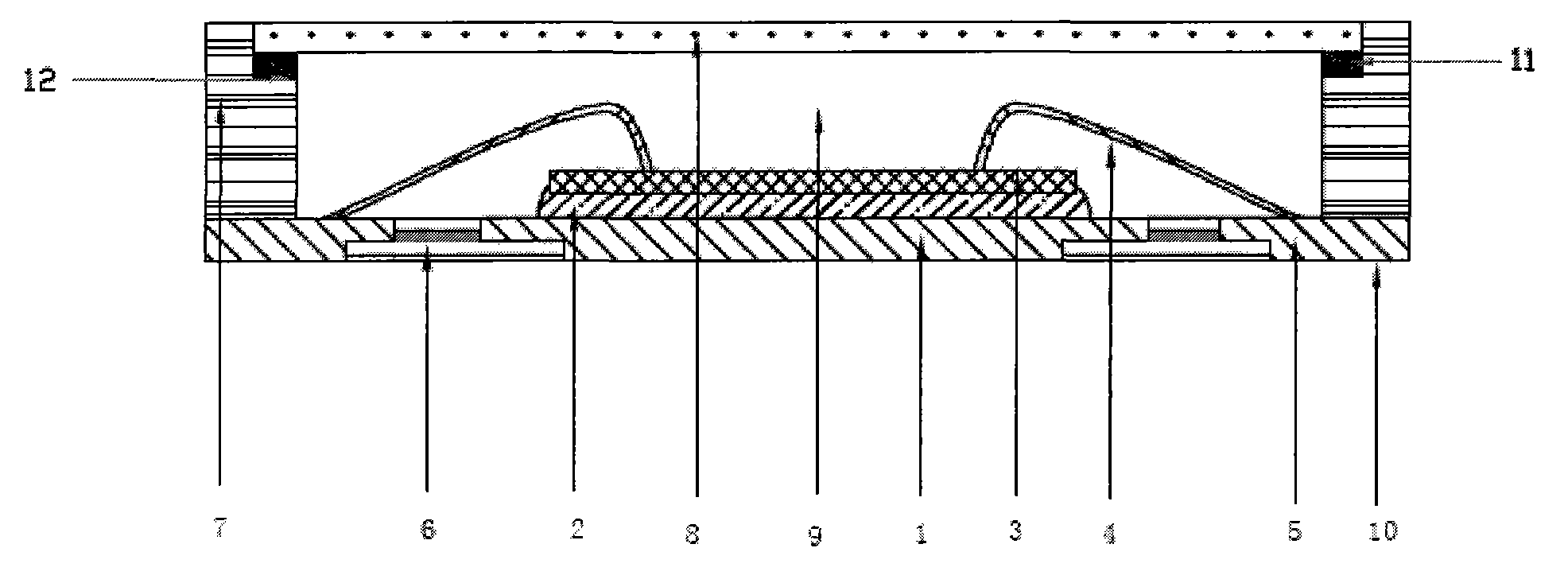

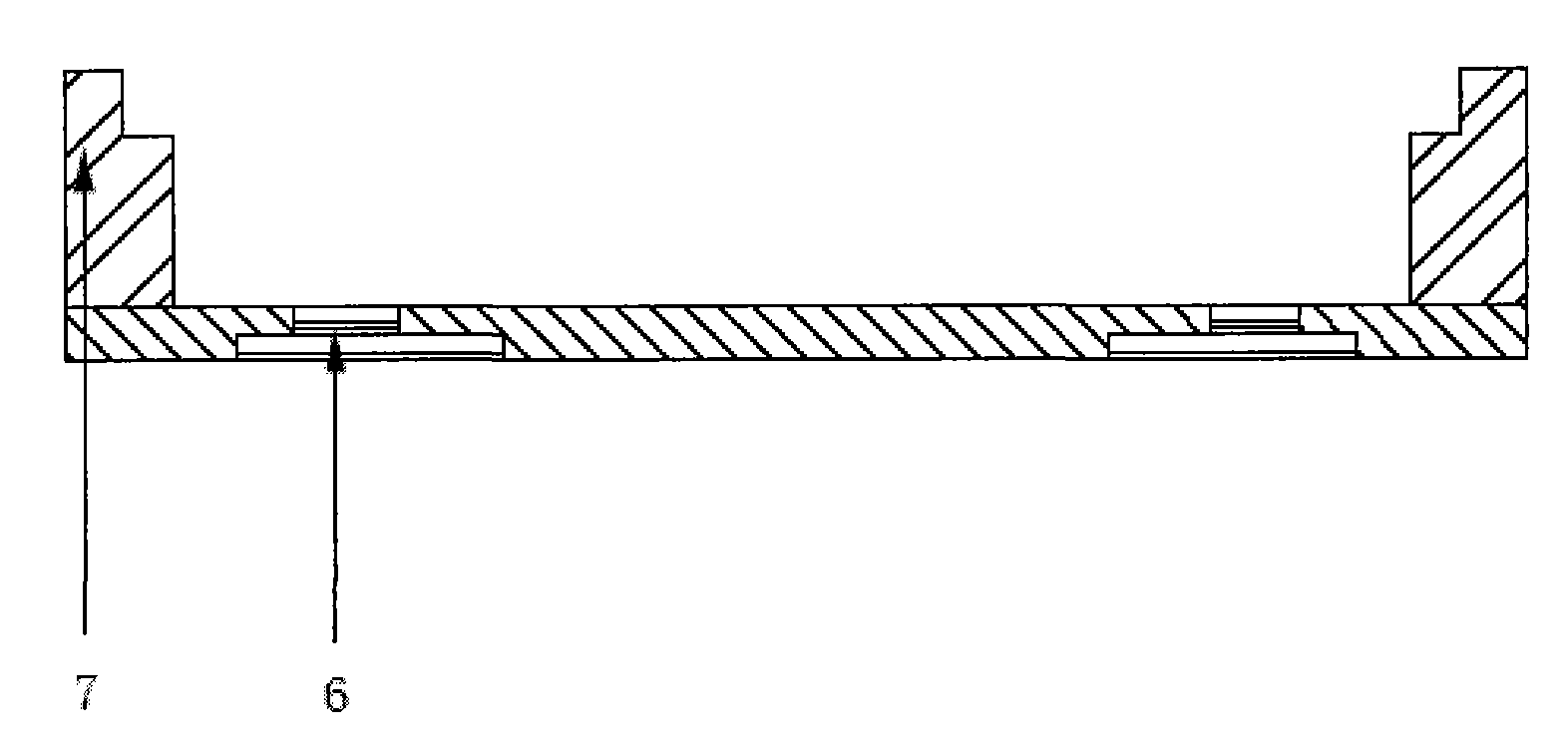

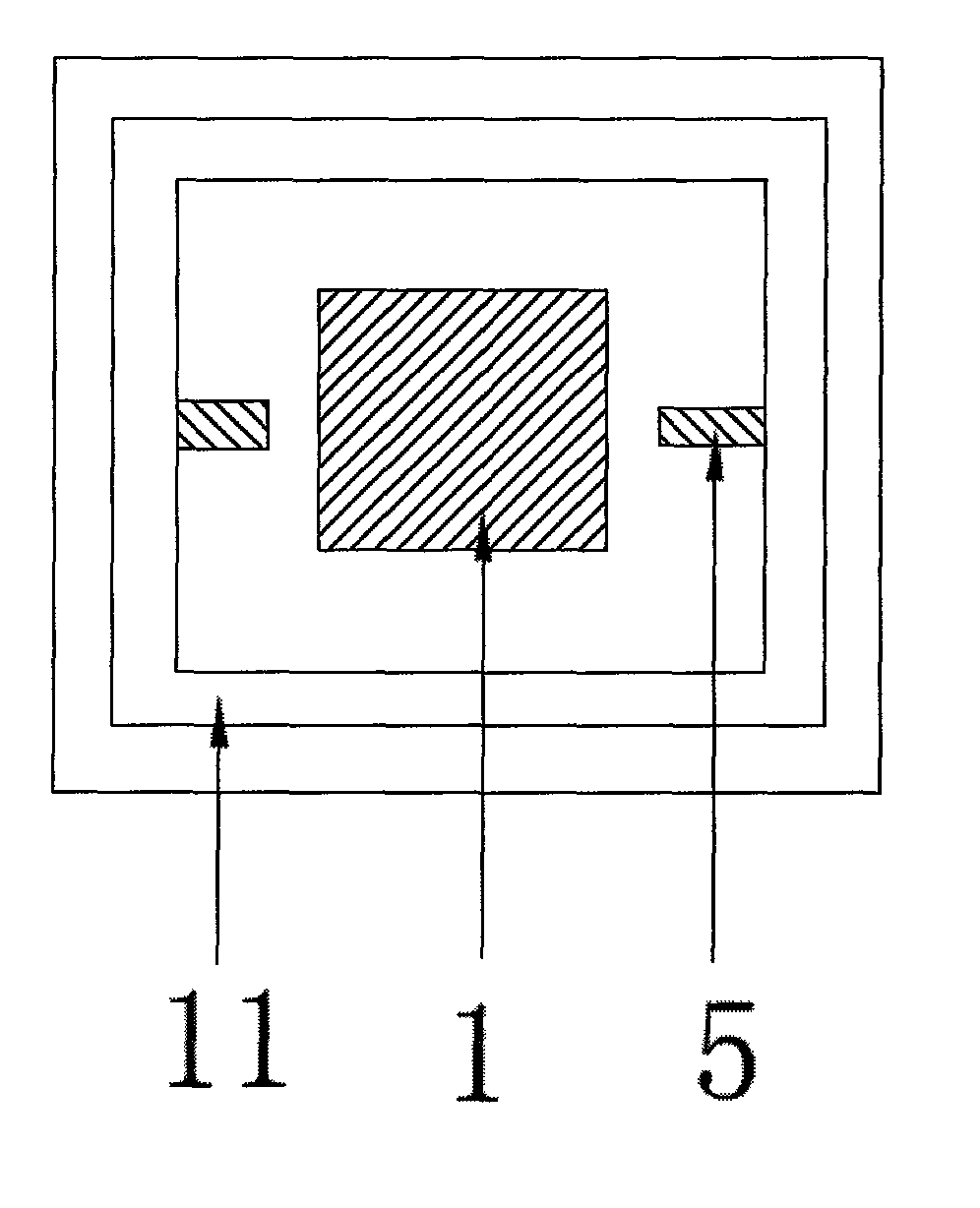

[0059] 1. Production of plastic-encapsulated outer cavity

[0060] A plastic encapsulation system is used to automatically transfer the lead frame into a plastic encapsulation mold, and a cavity with a height of 0.5 mm with a step is formed above the outer pins of the lead frame through plastic encapsulation, and the cavity covers the outer pins of the lead frame. The side of the lead frame carrier 1 and the space on the side of the pin 5 in the lead frame are connected by the plastic package 6, and the lower surface of the plastic package 6, the lead frame carrier (base island, PAD) 1 and the bottom surface of the outer pins of the lead frame are in the same position. a plane. Send the semi-finished product with the cavity ready for curing, and cure according to the conventional curing process after plastic sealing.

[0061] 2. Wafer thinning / scribing

[0062] First paste the adhesive film on the front, and then thin it on a special thinning machine to meet the process requ...

Embodiment 2

[0078] 1. Production of plastic-encapsulated outer cavity

[0079] A plastic encapsulation system is used to automatically transfer the lead frame into a plastic encapsulation mold, and a cavity with a height of 0.7 mm with a step is formed above the outer pins of the lead frame through plastic encapsulation, and the cavity covers the outer pins of the lead frame. The side of the lead frame carrier 1 and the space on the side of the pin 5 in the lead frame are connected by the plastic package 6, and the lower surface of the plastic package 6, the lead frame carrier (base island, PAD) 1 and the bottom surface of the outer pins of the lead frame are in the same position. a plane. Send the semi-finished product with the cavity ready for curing, and cure according to the conventional curing process after plastic sealing.

[0080] 2. Wafer thinning / scribing

[0081] First paste the adhesive film on the front, and then thin it on a special thinning machine to meet the process requ...

Embodiment 3

[0097] The overall process steps are the same as in Example 1 or 2, only in step 4 bonding, the time of ultrasonic wave and pressure added to the wiring rivet is 13ms, the ultrasonic frequency is 130KHZ, the output mode is current, the power is 44mw; the pressure output is 34gf ;

[0098] Step 6. The baking time during curing is as follows: heating time is 25 minutes, constant temperature time is 75 minutes, and cooling time is 35 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com