Double-sided sputtering silvered device of barrel-type quartz crystal

A quartz crystal, body type technology, applied in the field of double-sided sputtering quilt devices, can solve the problems of difficulty in manufacturing a round tube-shaped target, small loading of evaporating quilt devices, and affecting the bonding force of film layers, etc. The effect of good performance, strong binding force and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

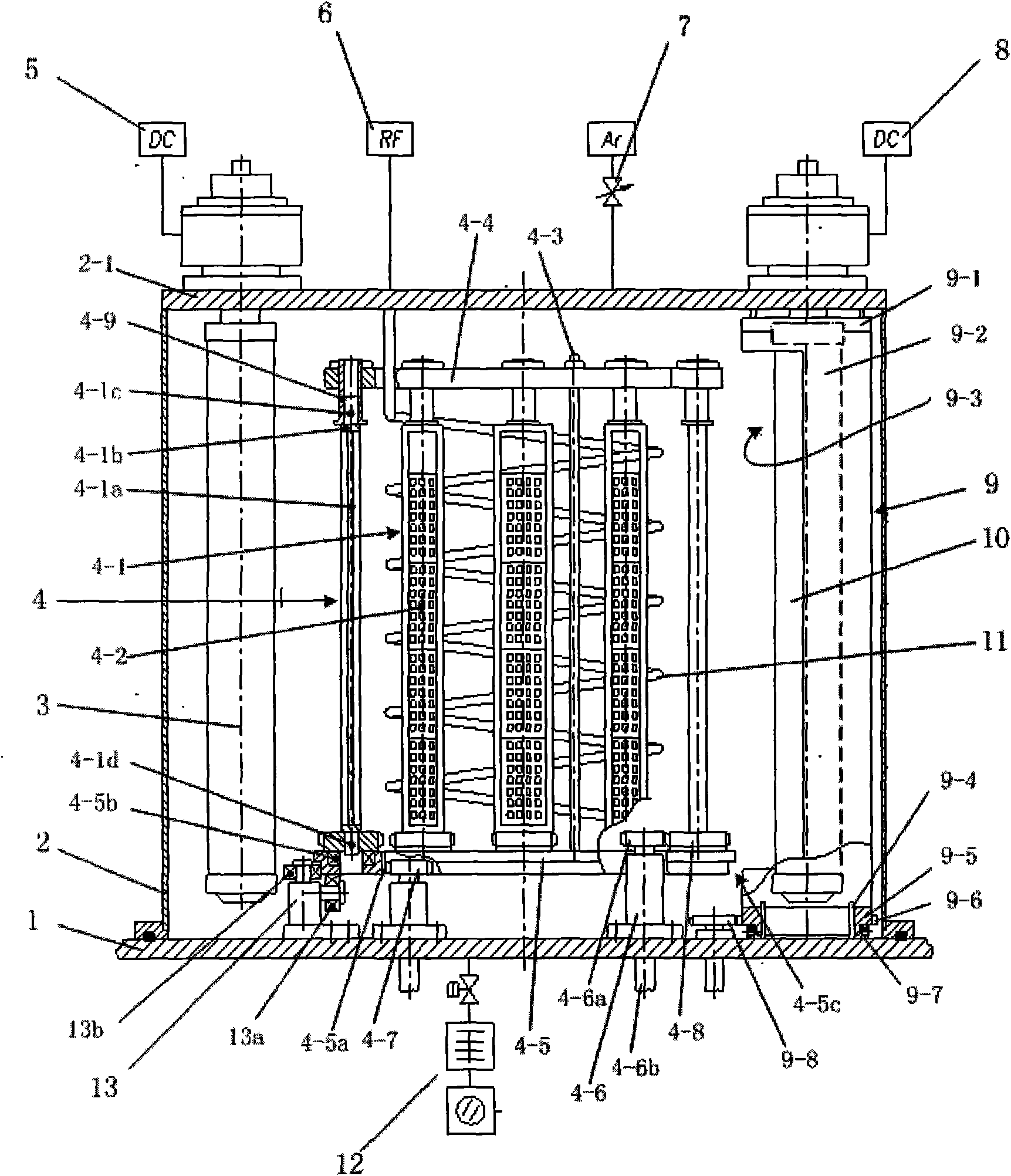

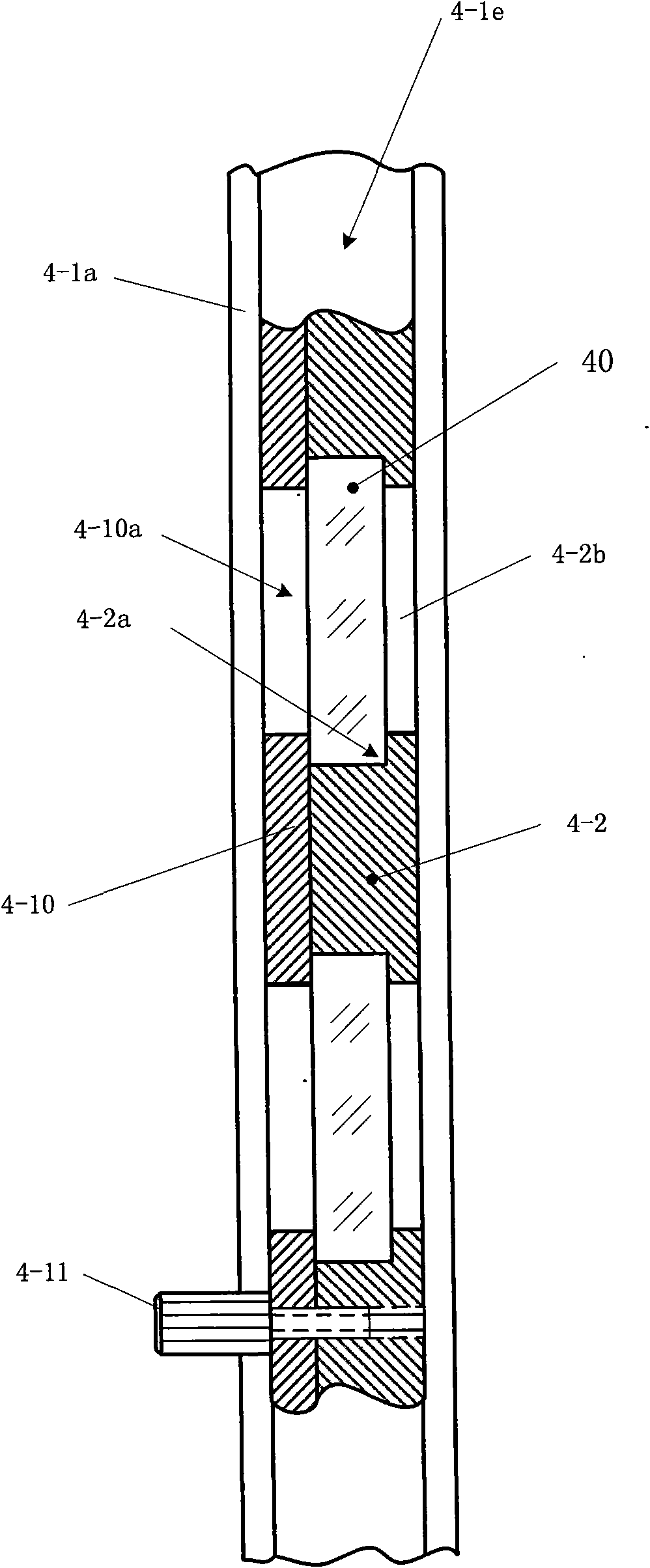

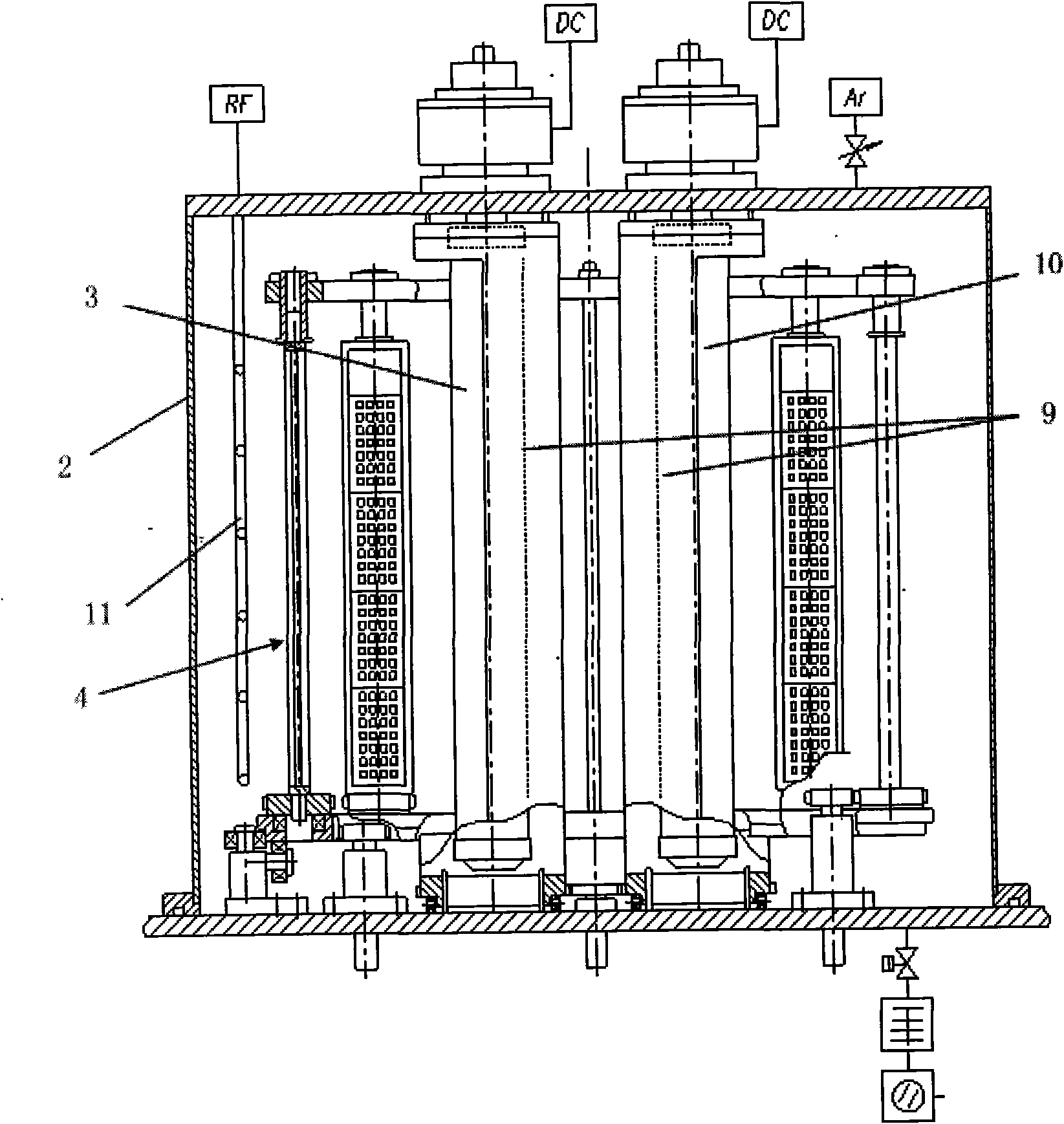

[0017] refer to figure 1 and figure 2 : the present invention comprises vacuum chamber body 2, vacuum pumping unit 12, workpiece frame 4, magnetron sputtering target 3,10, radio frequency plasma cleaner 11 and inert gas inflator 7, described vacuum pumping unit 12 and inert gas The inflators 7 are respectively connected to the vacuum cavity 2, the workpiece frame 4 is provided in the vacuum cavity 2, and the workpiece frame 4 can rotate, and the substrate frame 4-1 that can be turned over is installed on the workpiece frame 4, so The substrate holder 4-1 is provided with a slide tray 4-2, the slide tray 4-2 is provided with a quartz crystal sheet 40 and a mask sheet 4-10, and one side of the workpiece holder 4 is provided with at least Two magnetron sputtering targets 3 and 10 with barrier film covers 9, and a radio frequency plasma online cleaner 11 is arranged on the other side, wherein one magnetron sputtering target 10 is a sputtering target for coating a transition laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com