Method for preparing silicon carbide woodceramics

A technology for wood ceramics and silicon carbide, applied in the field of preparing silicon carbide wood ceramics, can solve the problems of limited mechanical properties, low ceramic density, large structural fluctuation, etc., and achieves the effects of simple and easy process, easy availability of raw materials and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, preparation silicon carbide wood ceramics

[0021] (1) poplar wood is pulverized to 400 orders;

[0022] (2) 400 order poplar wood flour is dried to moisture content 5% (mass percentage composition);

[0023] (3) The above-mentioned poplar wood powder is hot-pressed in a metal mold with a flat vulcanizer, at a molding temperature of 155°C and a molding time of 25 minutes to obtain a density of 0.95g / cm 3 body;

[0024] (4) Carbonize the above green body at 1200°C for 2 hours to obtain a carbon green body with a density of 0.80g / cm 3 ;

[0025] (5) The above-mentioned carbon blank was subjected to liquid-phase siliconizing at a vacuum degree of 30 Pa and a temperature of 1600° C. to obtain a silicon carbide wood ceramic 1 .

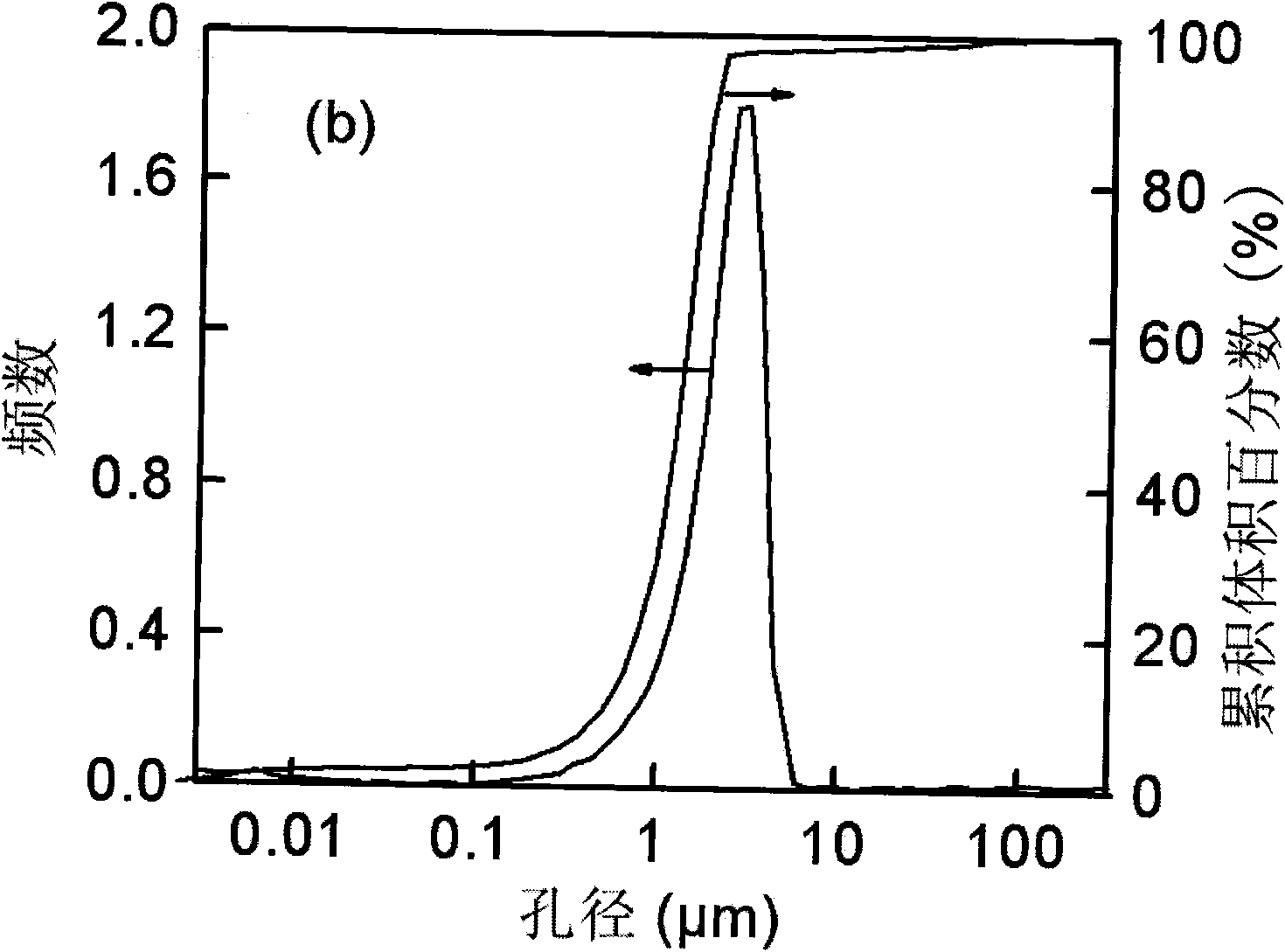

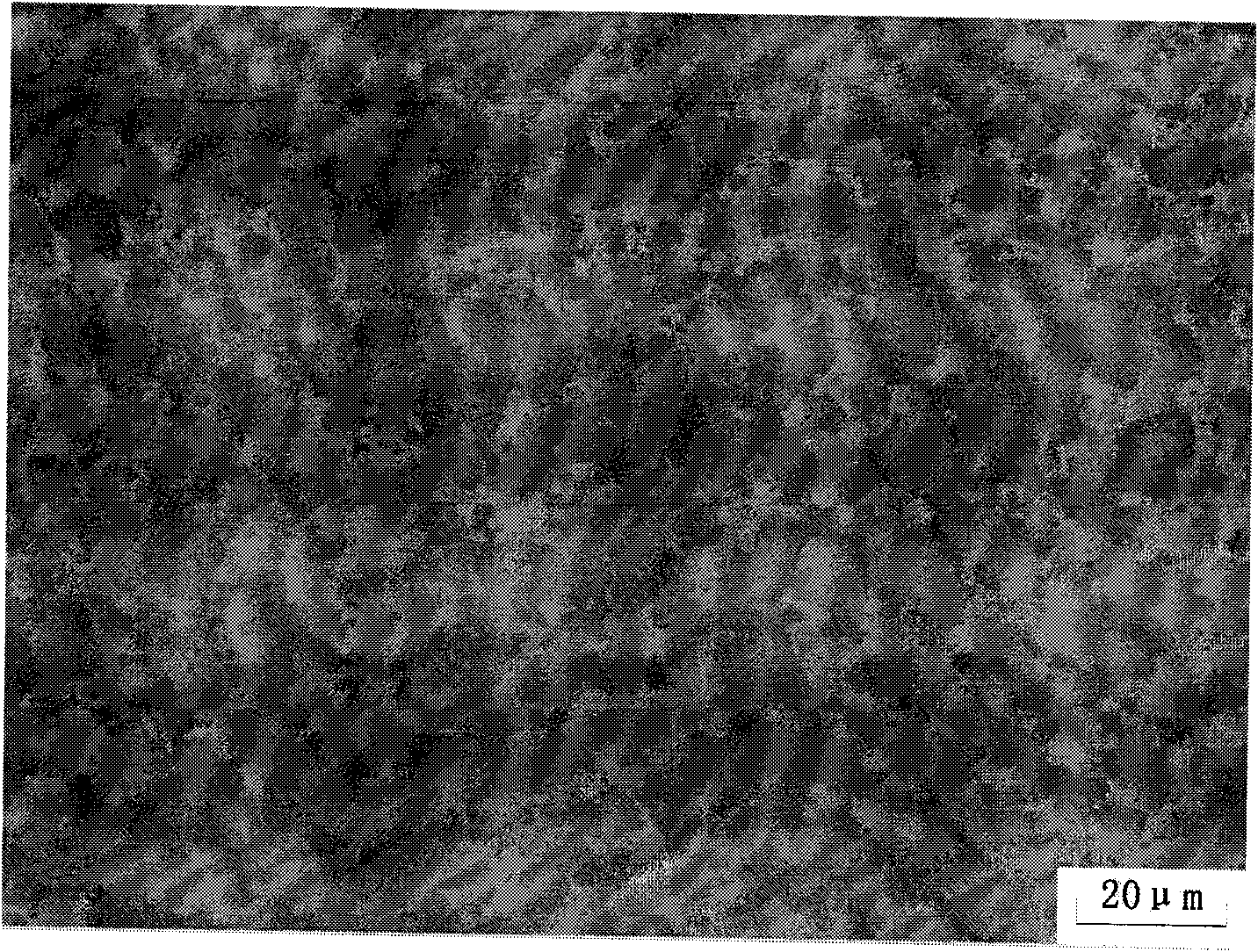

[0026] figure 1 with figure 2 They are the pore size distribution diagram of the carbon blank and the optical microstructure diagram of the silicon carbide wood-ceramic.

[0027] The prepared silicon carbide wood ceramics 1 wer...

Embodiment 2

[0029] Embodiment 2, preparation silicon carbide wood ceramics

[0030] (1) white pine wood is pulverized to 300 orders;

[0031] (2) the above-mentioned white pine wood powder is adjusted to a moisture content of 35% (mass percentage composition);

[0032] (3) The above-mentioned wood powder is made into a density of 0.90g / cm by continuous rolling method at a temperature of 185°C 3 the plate;

[0033] (4) Carbonize the above plate at 1500°C for 2 hours to obtain a carbon billet with a density of 0.76g / cm 3 ;

[0034] (5) Carry out vapor phase siliconizing on the above-mentioned carbon blank under a vacuum condition of 10 Pa and a temperature of 1750° C. to obtain a silicon carbide wood ceramic 2 .

[0035] The prepared silicon carbide wood-ceramic 2 was tested for density by the Archimedes drainage method, and the flexural strength was tested according to the national standard GB / T 6569-2006 (bending strength test method for fine ceramics), and the fracture toughness was ...

Embodiment 3

[0037] Embodiment 3, preparation silicon carbide wood ceramics

[0038] (1) poplar wood is pulverized to 800 orders;

[0039] (2) 800 order poplar wood flour is dried to moisture content 0% (mass percentage composition);

[0040] (3) The above-mentioned poplar wood powder is hot-pressed in a metal mold with a flat vulcanizer, and the molding temperature is 250°C, and the molding time is 25 minutes to obtain a density of 0.80g / cm 3 body;

[0041] (4) Carbonize the above green body at 1600°C for 2 hours to obtain a carbon green body with a density of 0.65g / cm 3 ;

[0042] (5) The above-mentioned carbon blank was subjected to liquid-phase siliconizing at a vacuum degree of 0.1 Pa and a temperature of 1450° C. to obtain silicon carbide wood ceramics 3 .

[0043]The prepared silicon carbide wood ceramics 3 were tested for density by the Archimedes drainage method, and the flexural strength was tested according to the national standard GB / T 6569-2006 (bending strength test metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com