Method for recovering medium-concentration and low-concentration vanadium in industrial sewage resulted from stone coal vanadium extraction

A technology of industrial wastewater and recovery method is applied in the field of recovery of low-concentration vanadium in industrial wastewater of vanadium extraction from stone coal, and achieves the effects of alleviating environmental pollution, reducing concentration, and reducing the concentration of vanadium.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

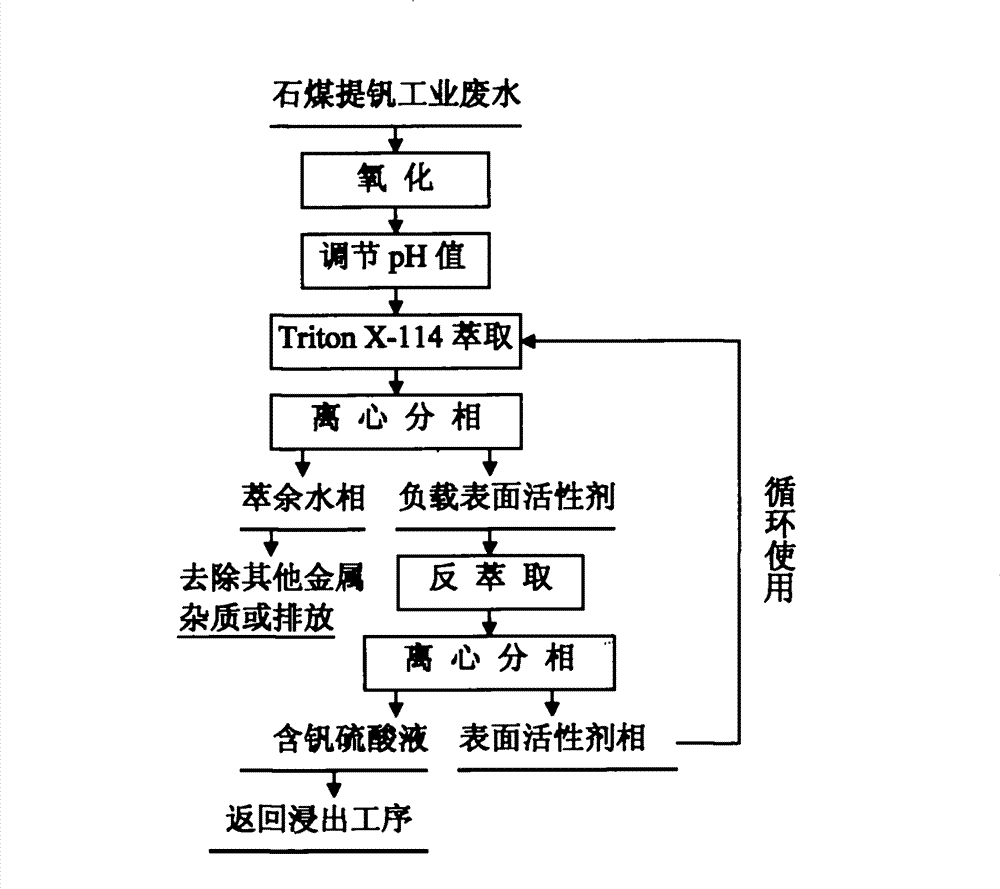

Method used

Image

Examples

example 1

[0028] Take 100ml of waste water for extracting vanadium from stone coal with a vanadium ion concentration of 1mg / L, add 0.05mg of sodium chlorate to oxidize the low-valent vanadium in the solution to pentavalent vanadium. Adjust the pH value of the solution to 3.0 with ammonia water with a mass fraction of 18-25%, add 3ml TritonX-114, place it in a 45°C water bath and heat for 10min to fully dissolve it. Centrifuge the phases in a centrifuge for 10 minutes while it is hot, and the vanadium ions are enriched in the micellar phase of the surfactant. Add 5ml of sulfuric acid solution with a mass fraction of 10% to the surfactant micelles that come out after phase separation, and heat to 45°C in a water bath again to fully dissolve it. The phases were separated by centrifugation for 10 min while hot. The recovery rate of vanadium was 91.6%. The vanadium-containing enrichment solution obtained by stripping can be returned to the vanadium extraction and leaching process of stone ...

example 2

[0030] Get 100ml of vanadium-extracting wastewater from stone coal containing 5mg / L of vanadium, add 0.17mg of sodium chlorate to oxidize the low-valent vanadium in the solution to pentavalent vanadium. Adjust the pH value of the solution to 3.0 with a mass fraction of 18-25%, add 4ml TritonX-114, place in a 50°C water bath and heat for 15min to fully dissolve it. Centrifuge the phases in a centrifuge for 15 minutes while hot, and the vanadium ions are enriched in the micellar phase of the surfactant. Add 5ml of sulfuric acid solution with a mass fraction of 10% to the surfactant micelles after phase separation, and heat to 50°C in a water bath again to fully dissolve it. The phases were separated by centrifugation for 15 min while hot. The recovery rate of vanadium was 82.1%. The vanadium-containing enrichment solution obtained by stripping can be returned to the vanadium extraction and leaching process of stone coal, and the separated surfactant can be recycled.

example 3

[0032] Take 100ml of vanadium-extracting wastewater from stone coal containing 10mg / L of vanadium, add 0.40mg of sodium hypochlorite to oxidize the low-valent vanadium in the solution to pentavalent vanadium. Adjust the pH value of the solution to 3.5 by using ammonia water with a mass fraction of 18-25%, add 5ml TritonX-114, place it in a water bath at 60°C and heat it for 20min to fully dissolve it. Centrifuge the phases in a centrifuge for 15 minutes while hot, and the vanadium ions are enriched in the micellar phase of the surfactant. Add 5ml of sulfuric acid solution with a mass fraction of 10% to the surfactant micelles after phase separation, and heat to 60° C. in a water bath again to fully dissolve it. The phases were separated by centrifugation for 15 min while hot. The recovery rate of vanadium is 76.1.3%. The vanadium-containing enrichment solution obtained by stripping can be returned to the vanadium extraction and leaching process of stone coal, and the separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com