Surface-texturing n-type ZnO-based transparent conductive film and preparation method thereof

A technology of transparent conductive film and surface texture, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of damage, complex processing procedures, and difficulty in large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

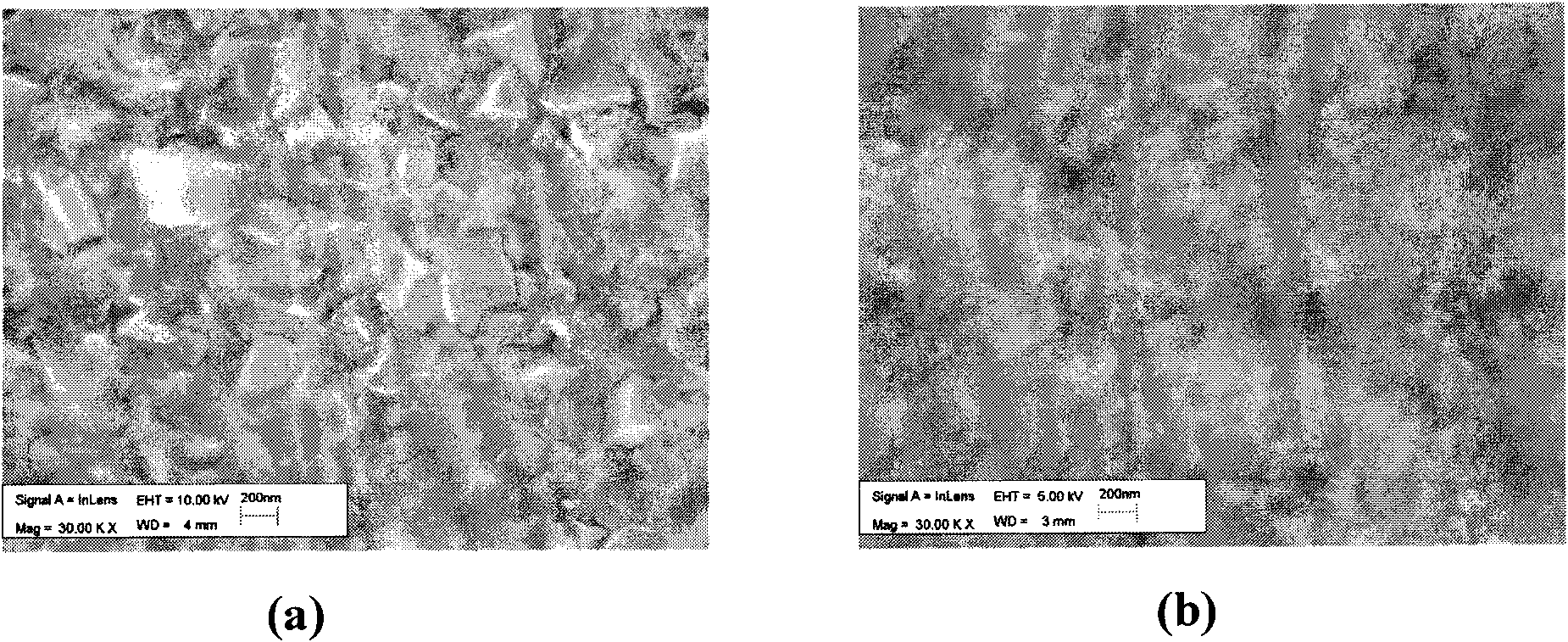

[0034] ZnO-based doping compound (ZnO:Al) is used as the target material, the doping ratio of Al is 2.0mol%, and ordinary glass is used as the substrate, and the background vacuum is pumped to 2.0×10 -4 Pa, with high-purity argon as the working gas, and a small amount of O 2 and H 2 Gas (O 2 and H 2 accounted for 5% and 2% of the total gas flow respectively), the working pressure was maintained at 1.2Pa, the substrate temperature was 150°C, the distance between the target and the substrate was set at 7cm, DC magnetron sputtering was adopted, and the sputtering power was 80W. The deposition time is 40min. The surface morphology of the prepared film samples is as follows figure 1 (a) shown. The results show that the AZO film prepared by the invention has good crystallization, large grain size, and obvious grain boundaries between grains.

Embodiment 2

[0036] ZnO-based doping compound (ZnO:Al) is used as the target material, the doping ratio of Al is 2.0mol%, and ordinary glass is used as the substrate, and the background vacuum is pumped to 2.0×10 -4 Pa, using high-purity argon as the working gas, the working pressure is maintained at 1.2Pa, the substrate temperature is 150°C, the distance between the target and the substrate is set at 7cm, DC magnetron sputtering is used, the sputtering power is 80W, the deposition time for 40min. Using pure Ar gas as the working gas, under the same process conditions, the surface morphology of the obtained film is as follows: figure 1 (b). Obviously, there is no 2 and H 2 When the gas is fed, the grain boundaries of the AZO film are relatively disordered, and the grain size is small; while in Example 1, a small amount of O 2 and H 2 After being degassed, Al atoms are effectively incorporated into the ZnO lattice instead of at the grain boundaries, the grains grow significantly, and t...

Embodiment 3

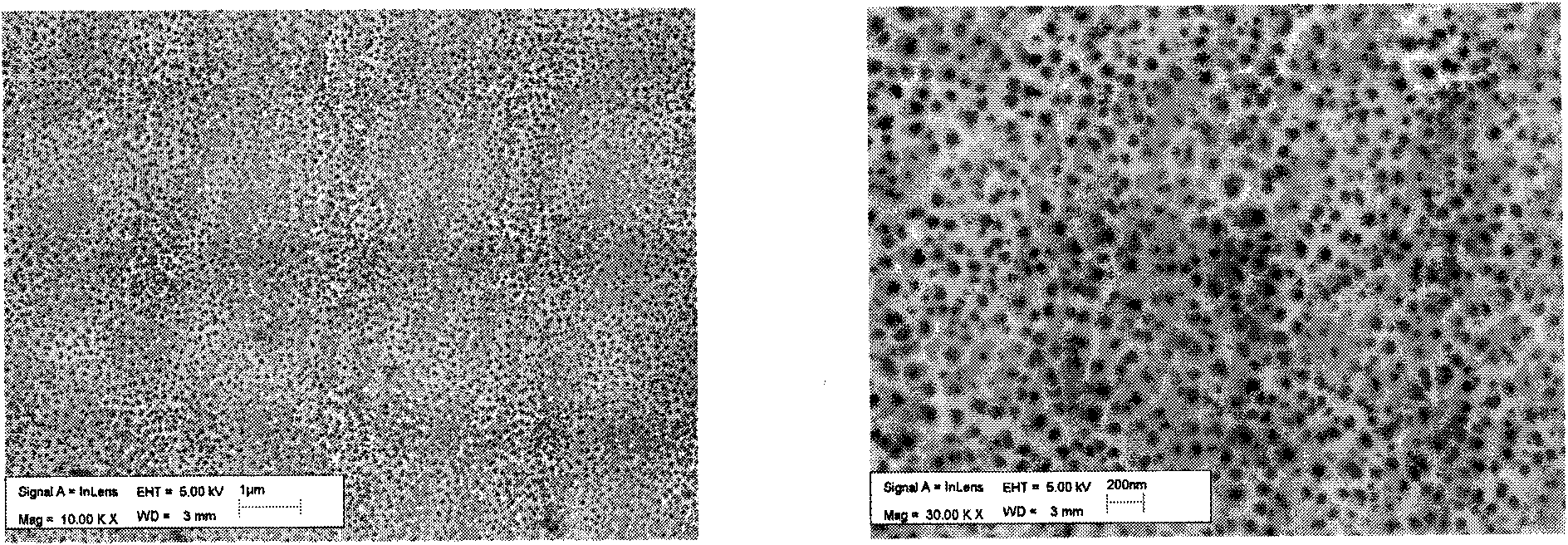

[0038] ZnO-based doping compound (ZnO:Al) is used as the target material, the doping ratio of Al is 2.0mol%, and ordinary glass is used as the substrate, and the background vacuum is pumped to 2.0×10 -4 Pa, with high-purity argon as the working gas, and a small amount of O 2 and H 2 Gas (O 2 and H 2 accounted for 5% and 2% of the total gas flow respectively), the working pressure was maintained at 1.2Pa, the substrate temperature was 90°C, the distance between the target and the substrate was set at 7cm, DC magnetron sputtering was adopted, and the sputtering power was 80W. The deposition time is 40min. Next, adjust O 2 and H 2 Gas volume (O 2 and H 2 accounted for 0.05% and 5.0% of the total gas flow respectively), the working pressure was maintained at 0.3Pa, the substrate temperature was room temperature, the distance between the target and the substrate was set at 5cm, DC magnetron sputtering was adopted, and the sputtering power was 140W. The time is 10 minutes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com