Ordered mesoporous carbon-sulphur nano composite positive pole material and preparation method thereof

A nano-composite, cathode material technology, applied in electrode manufacturing, battery electrodes, active material electrodes, etc., can solve the problems of poor cycle performance and low conductivity, and achieve good high electricity, high sulfur utilization, and good cycle retention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Melt 10.0g phenol in a water bath at 40-42°C in a long-necked flask, add 2.13g 20wt% NaOH aqueous solution under stirring, continue stirring for 10min, then add 17.7g formalin (37wt% formaldehyde) dropwise below 50°C 70-75 It was further stirred for 1 h at °C. Cool to room temperature, adjust the pH to about 7.0 with hydrochloric acid, and dry under vacuum at 50°C to remove water. The product was dissolved in ethanol to prepare a 20 wt.% solution to obtain a phenolic resin prepolymer for use.

[0028] At 40°C, 8g F127(EO 106 PO 70 EO 106 ) and 5.0g of 0.2M hydrochloric acid solution were dissolved in 40g of absolute ethanol, stirred to obtain a clear solution, adding .25.0g mass percent concentration of 20wt.% phenolic resin prepolymer and 10.4g tetraethyl orthosilicate (TEOS), Stir for 5 hours to make TEOS hydrolyze and polycondense initially. The solution was transferred to a watch glass, left to volatilize at room temperature for 5-10 hours, and then heated in a...

Embodiment 2

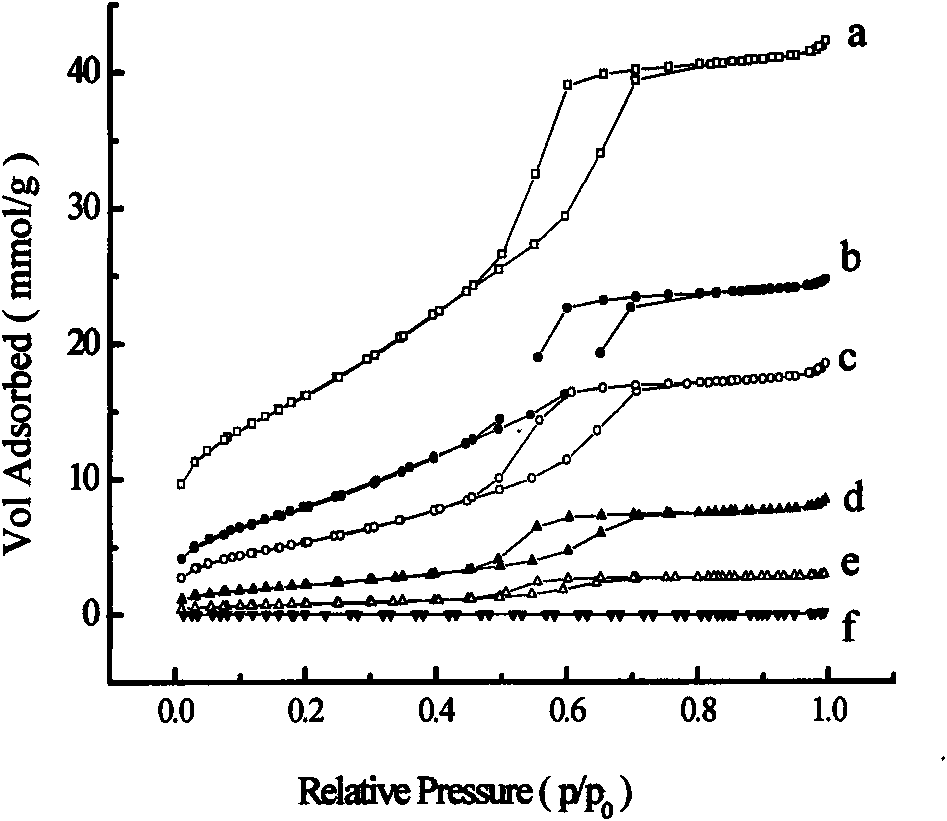

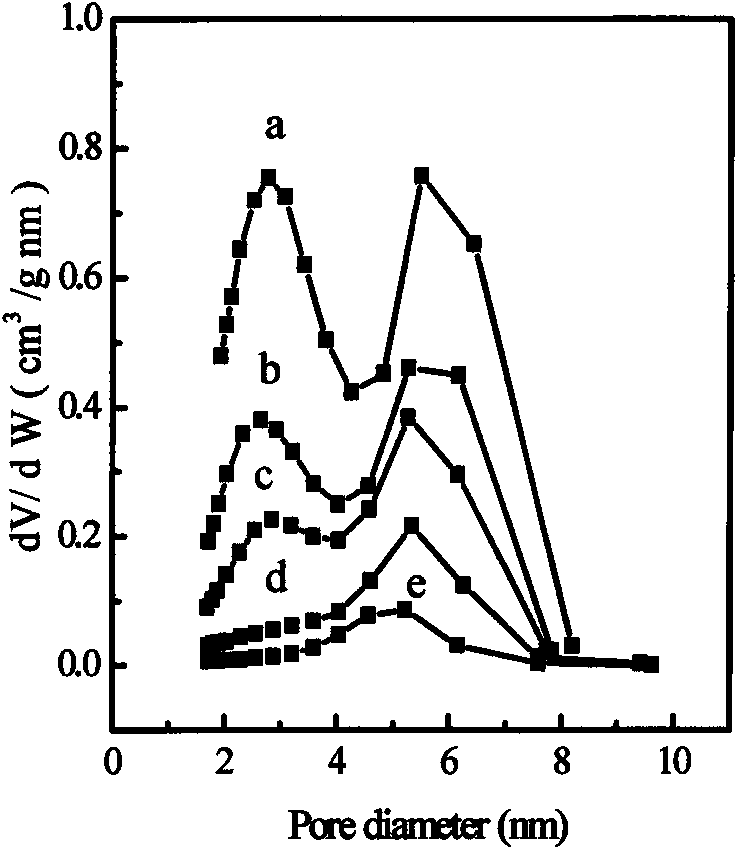

[0030] After grinding and mixing 0.40 g of the ordered mesoporous carbon prepared in Example 1 and 0.10 g of sublimed sulfur, they were put into a closed container and heat-treated at 150° C. for 12 hours to obtain 0.50 g of ordered mesoporous carbon with a sulfur content of 20wt.%. Sulfur nanocomposites.

Embodiment 3

[0032] After grinding and mixing 0.325g of the ordered mesoporous carbon prepared in Example 1 and 0.175g of sublimed sulfur, put it into a closed container, heat treatment at 150°C for 12h, and obtain 0.50g of ordered mesoporous carbon with a sulfur content of 35wt.%- Sulfur nanocomposites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com