Polyimide precursor and photosensitive resin composition containing polyimide precursor

A technology of polyimide precursor and photosensitive resin, which is applied in the field of photosensitive resin composition and photosensitive film, and can solve problems such as control and difficult structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

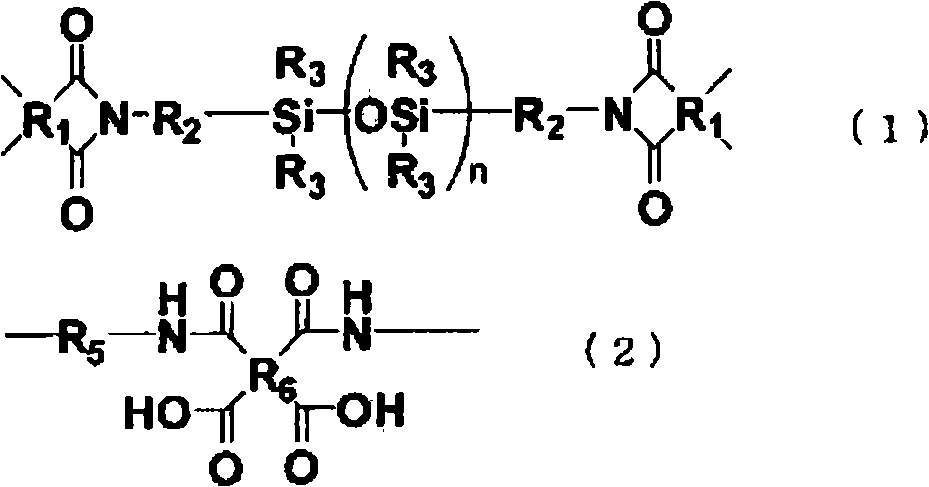

[0196] Under a nitrogen atmosphere, triglyme (71.75g), toluene (20.0g), siloxane diamine (KF-8010, 18.15mmol), and TMEG (24.21mmol) were added into a detachable flask. Heat and stir at 120°C for 1 hour. Next, install a Dean-Stark apparatus and a reflux device, and heat and stir at 180° C. for 1 hour. After removing the azeotropic solvent toluene, the mixture was cooled to 25°C, then APB-N (11.55 mmol) was added, and after stirring for 10 minutes, TMEG (5.79 mmol) was added and stirred at 25°C for 8 hours. Triglyme was added after stirring so that the density|concentration of a polymer solid content might become 25 mass %, and the triglyme solution of the polyimide precursor (1) was obtained. The weight average molecular weight and z / (x+y+z) are listed in Table 1.

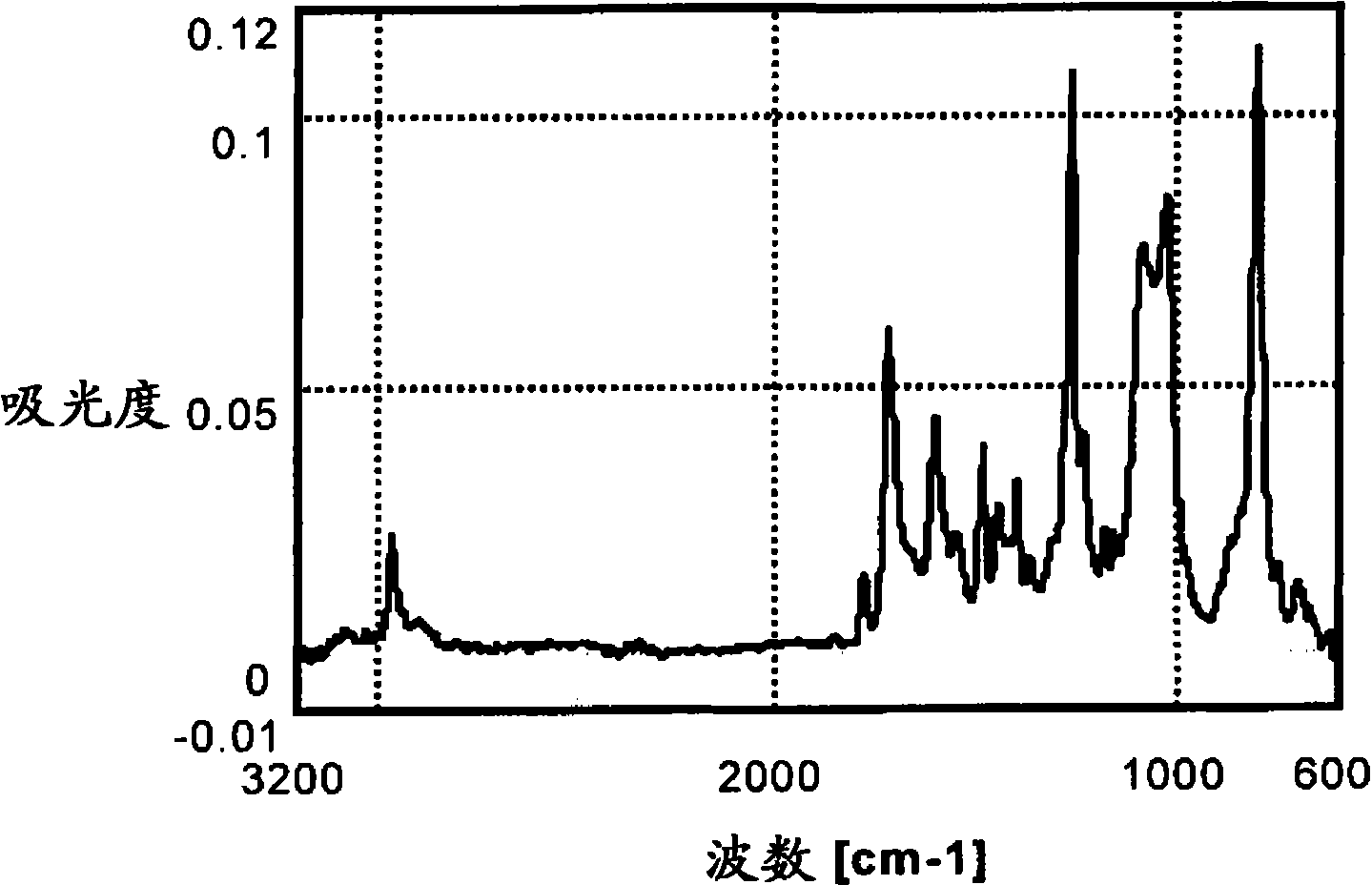

[0197] The thermal stability of the polyimide precursor (1) was evaluated by the thermal stability evaluation method mentioned above. The results of this evaluation are listed in Table 1. Moreover, NMR measureme...

Embodiment 2

[0203] Triglyme (36.8 g), toluene (20.0 g), siloxanediamine (X-22-161A, 5.73 mmol), TMEG (7.29 mmol) were added to a separable flask under nitrogen atmosphere , heated and stirred at 120° C. for 1 hour. Next, install a Dean-Stark apparatus and a reflux device, and heat and stir at 180° C. for 1 hour. After removing the azeotropic solvent toluene, the mixture was cooled to 25°C, then APB-N (9.58mmol) was added, and after stirring for 10 minutes, TMEG (8.02mmol) was added and stirred at 25°C for 8 hours. Triglyme was added after stirring so that the density|concentration of a polymer solid content might become 25 mass %, and the triglyme solution of a polyimide precursor was obtained. The weight average molecular weight, z / (x+y+z) and thermal stability evaluation results are listed in Table 1.

[0204] Compound B-1 (20 mass parts) and TBXP (10 mass parts) were mixed with 100 mass parts of polyimide precursors (2), and the photosensitive resin composition was prepared. Except ...

Embodiment 3

[0206] Under a nitrogen atmosphere, triglyme (50.0g), toluene (20.0g), siloxane diamine (KF-8010, 15.0mmol), and ODPA (20.0mmol) were added to a detachable flask, and Heat and stir at 120°C for 1 hour. Next, install a Dean-Stark apparatus and a reflux device, and heat and stir at 180° C. for 1 hour. After removing the azeotropic solvent toluene, it was cooled to 25°C, then APB-N (13.0 mmol) was added, and after stirring for 10 minutes, TMEG (10.0 mmol) was added and stirred at 25°C for 8 hours. Triglyme was added after stirring so that the density|concentration of a polymer solid content might become 25 mass %, and the triglyme solution of the polyimide precursor (3) was obtained. The weight average molecular weight, z / (x+y+z) and thermal stability evaluation results are listed in Table 1.

[0207] Compound B-1 (20 mass parts) and TBXP (10 mass parts) were mixed with 100 mass parts of polyimide precursors (3), and the photosensitive resin composition was prepared. Except ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com