Method for rapidly reducing and roasting as well as synchronously dephosphorizing and extracting iron at high temperature of high-silicon high-phosphorus iron ore

A high-temperature, high-speed, high-silicon technology, applied in the field of metallurgy, can solve the problems of cold bending performance and plasticity reduction, high cost of beneficiation methods, low recovery rate, etc., to achieve the effect of reducing slag volume, promoting mining industry development, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The composition of the dephosphorization agent is slaked lime, hydrogenated rosin, and the reducing agent is ordinary lignite.

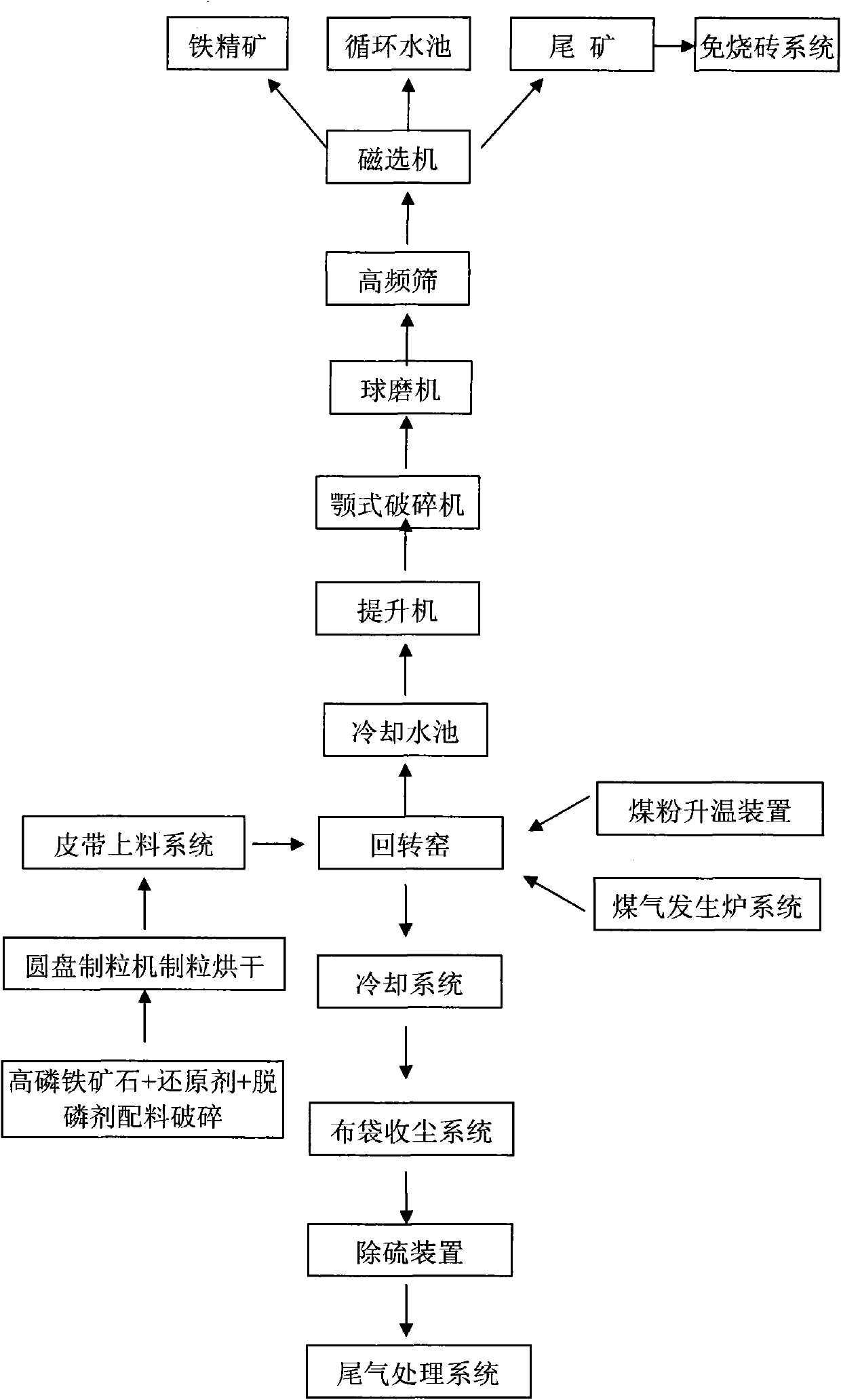

[0028] The production process steps are as follows:

[0029] 1. Crush high-phosphorus and high-silicon iron ore and lignite to -150 mesh, and crush slaked lime and hydrogenated rosin to 200 mesh.

[0030] 2. Ingredients: 70% of iron ore, 21.7% of slaked lime, 8% of lignite and 0.3% of hydrogenated rosin are mixed evenly by weight percentage.

[0031] 3. The evenly stirred mixture is input to the disc granulator for granulation and dried.

[0032] 4. Evenly put the dried mixed particles into the rotary kiln from the kiln tail, and use high-pressure pulverized coal and gas to raise the temperature of the kiln head (using high-efficiency energy-saving gas generator and pulverized coal heating device, both belong to the prior art), and the temperature is controlled at 1100 -1200°C, stay in the kiln for 2 hours, and the discharged product is quen...

Embodiment 2

[0042] 1. Crush high-phosphorus and high-silicon iron ore and lignite to -150 mesh, and crush slaked lime and hydrogenated rosin to 200 mesh.

[0043] 2. Ingredients: 69.2% of iron ore, 25% of slaked lime, 12% of lignite and 0.1% of hydrogenated rosin are mixed evenly by weight percentage.

[0044] The following production process steps are the same as in Example 1.

Embodiment 3

[0046] 1. Crush high phosphorus and high silicon iron ore and lignite to -150 mesh, and crush slaked lime to 200 mesh.

[0047] 2. Ingredients: 70% iron ore, 20% slaked lime, and 10% lignite are mixed uniformly by weight.

[0048] The following production process steps are the same as in Example 1.

[0049] The above-mentioned rotary kiln is a cylindrical high-temperature reactor placed on several pairs of support wheels with a slight tilt. During operation, the kiln body rotates at a certain speed, and the iron-containing raw materials and reduced coal (part or all) are continuously added from the feeding end of the kiln tail. With the rotation of the kiln body, the solid materials continue to roll and move to the discharge end of the kiln head. The discharge end is equipped with a main fuel burner and a recovery coal injection device to provide part of the heat and reducing agent required by the process. The volatile matter released by burning coal, the CO produced by redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com