Method for processing protein foaming agent by irradiation

A protein foaming agent and a protein foaming technology are applied in the field of irradiation treatment of protein foaming agents, which can solve the problems of environmental pollution, products that cannot meet the requirements of green environmental protection, and large odor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

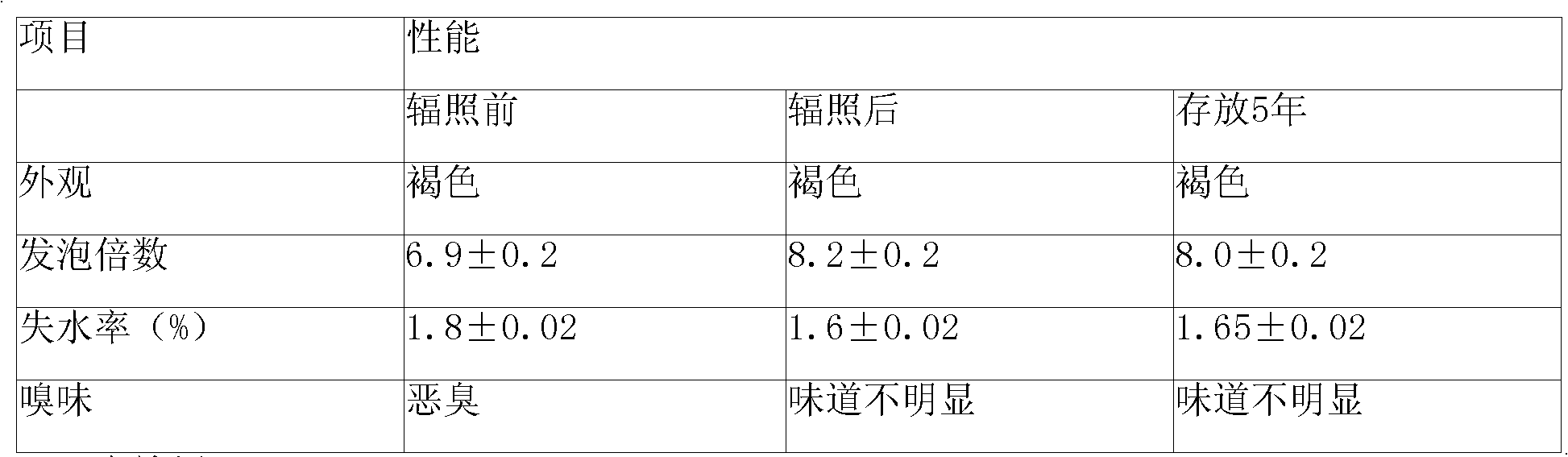

Examples

Embodiment 1

[0016] ①Extraction of protein solution:

[0017] The protein is extracted from the sludge by the usual method, and then concentrated to a certain concentration (about 30%).

[0018] ②Irradiation treatment:

[0019] Accurately weigh 100g of 30% protein solution with an analytical balance, put it in a plastic bottle and seal it, and then irradiate it with an irradiation dose of 1KGy at room temperature. 60 Co γ-ray irradiation for 30min.

[0020] ③Assessment of sense of smell:

[0021] The olfactory smell of the protein solution was determined by a precision electronic nose. Sampling is directly taken from the sample bottle, and the headspace sampling method is directly analyzed by the electronic nose under natural conditions at room temperature.

[0022] ④ Determination of foaming ratio and foam stability:

[0023] Foaming ratio measurement method: Dilute the obtained protein solution to a protein dilution with a concentration of 3%, then take 10mL of the protein dilution,...

Embodiment 2

[0034] The extraction of the protein solution is the same as in Example 1, the concentrated protein solution is placed in a plastic bottle and sealed, and then at room temperature the irradiation dose is 5KGy 60 Irradiate under Co gamma ray for 60min; carry out the mensuration of sense of smell, foaming multiple and foam stability with the operating method of embodiment 1. Finally spray dry and seal the package.

Embodiment 3

[0036] The extraction of the protein solution is the same as in Example 1, the concentrated protein solution is placed in a plastic bottle and sealed, and then at room temperature the irradiation dose is 10KGy 60 Irradiate 120min under Co gamma ray; Carry out the mensuration of sense of smell, foaming multiple and foam stability with the operation method of embodiment 1. Finally spray dry and seal the package.

[0037] The protein foaming agent prepared by the above method can be used to prepare protein foam fire extinguishing agent and foam concrete by conventional methods. The prepared protein foam fire extinguishing agent does not have the stench of animal protein, and the cost is lower than that of vegetable protein. All fire extinguishing properties meet the fire protection indicators, and it is biodegradable. It is a safe and green environmental protection product; and the prepared foam concrete has fine and uniform porosity. , compressive strength (5-7.5MPa), good ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com