Heat exchanger using microporous hydrophobic membrane for strengthening heat exchange

A technology to strengthen heat exchange and heat exchangers, applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

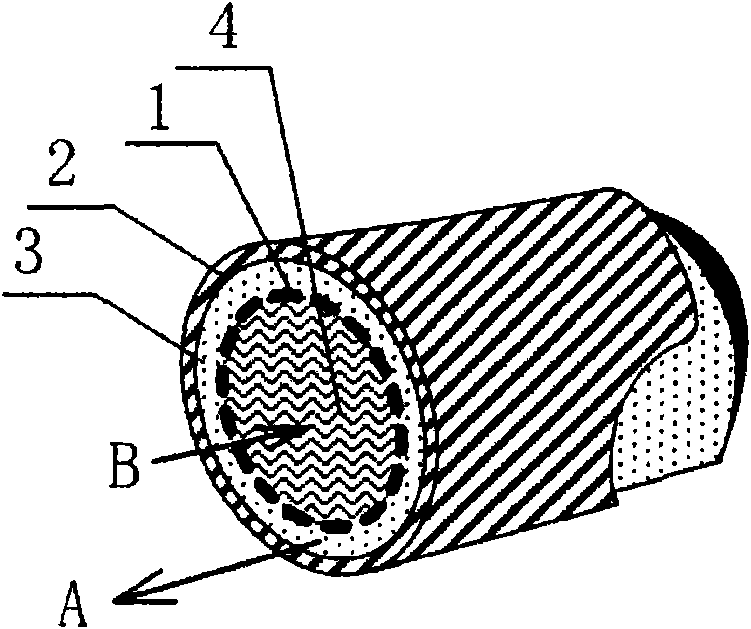

[0034] see figure 1 , the present invention utilizes microporous hydrophobic film to strengthen the heat exchanger of heat exchange, and the overall shape is a circular tube, and is mainly used for the object that needs to be cooled to be smaller particle or liquid material. The outer shell (metal tube 2 ) of the heat exchanger is the heat exchange surface, and the material of the metal tube 2 can be made of a heat conductor, such as but not limited to copper, iron, aluminum, stainless steel and the like. The inside of the metal tube 2 is divided into two parts by a hydrophobic microporous membrane 1 , a main flow channel 3 (ie, an annular channel outside the membrane) and an auxiliary flow channel 4 (ie, an annular channel inside the membrane). The microporous hydrophobic membrane of the present invention is a polytetrafluoroethylene (PTFE) membrane, the average diameter of membrane holes is 0.1mm, the porosity is 70%, and the membrane thickness is 0.2mm. The fluids of the m...

Embodiment 2

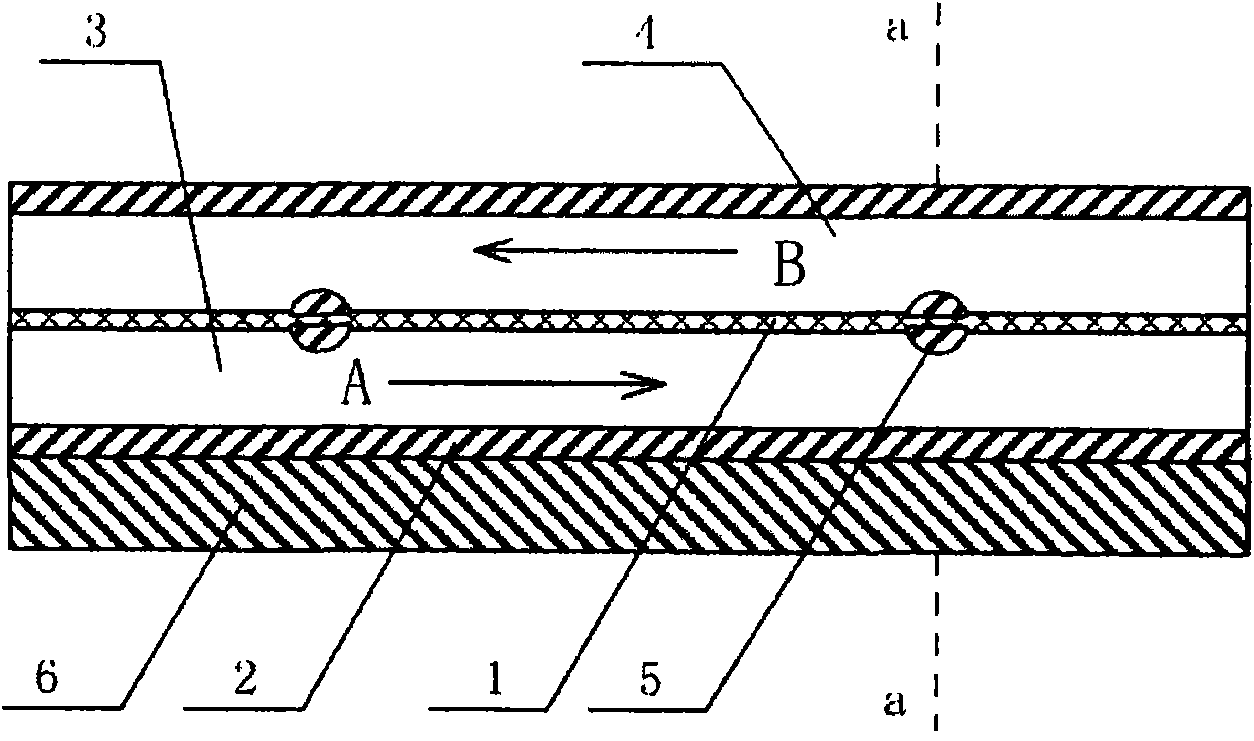

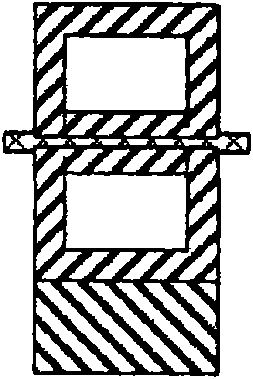

[0037] Taking the cooling of a high-power laser palladium strip as an example, the overall shape of the heat exchanger of the present invention is a rectangle, and its structure is shown in Figure 2. The shell 2 of the heat exchanger is made of brass. The interior of the heat exchanger is divided into two parts by a hydrophobic microporous membrane 1, the main flow channel 3 (that is, the lower pipe in Figure 2) and the auxiliary flow channel 4 (that is, the upper pipe in Figure 2), and the shell of the heat exchanger The wall thickness of 2 is 1 mm, the heights of the main flow channel and the auxiliary flow channel are respectively 2.5 mm, and the length and width are the same as those of the laser palladium bar 6 . The microporous hydrophobic membrane is a PTFE membrane, the average diameter of membrane pores is 0.1mm, the porosity is 70%, and the membrane thickness is 0.2mm. The main flow channel 3 of the heat exchanger is in contact with the palladium strip 6 of the laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com