Method and device for treating micro-polluted surface water

A surface water, micro-pollution technology, applied in aerobic process treatment, sustainable biological treatment, chemical instruments and methods, etc., can solve the problems of low operating flux, inability to remove ammonia nitrogen, etc., to improve membrane flux, easy to replace , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

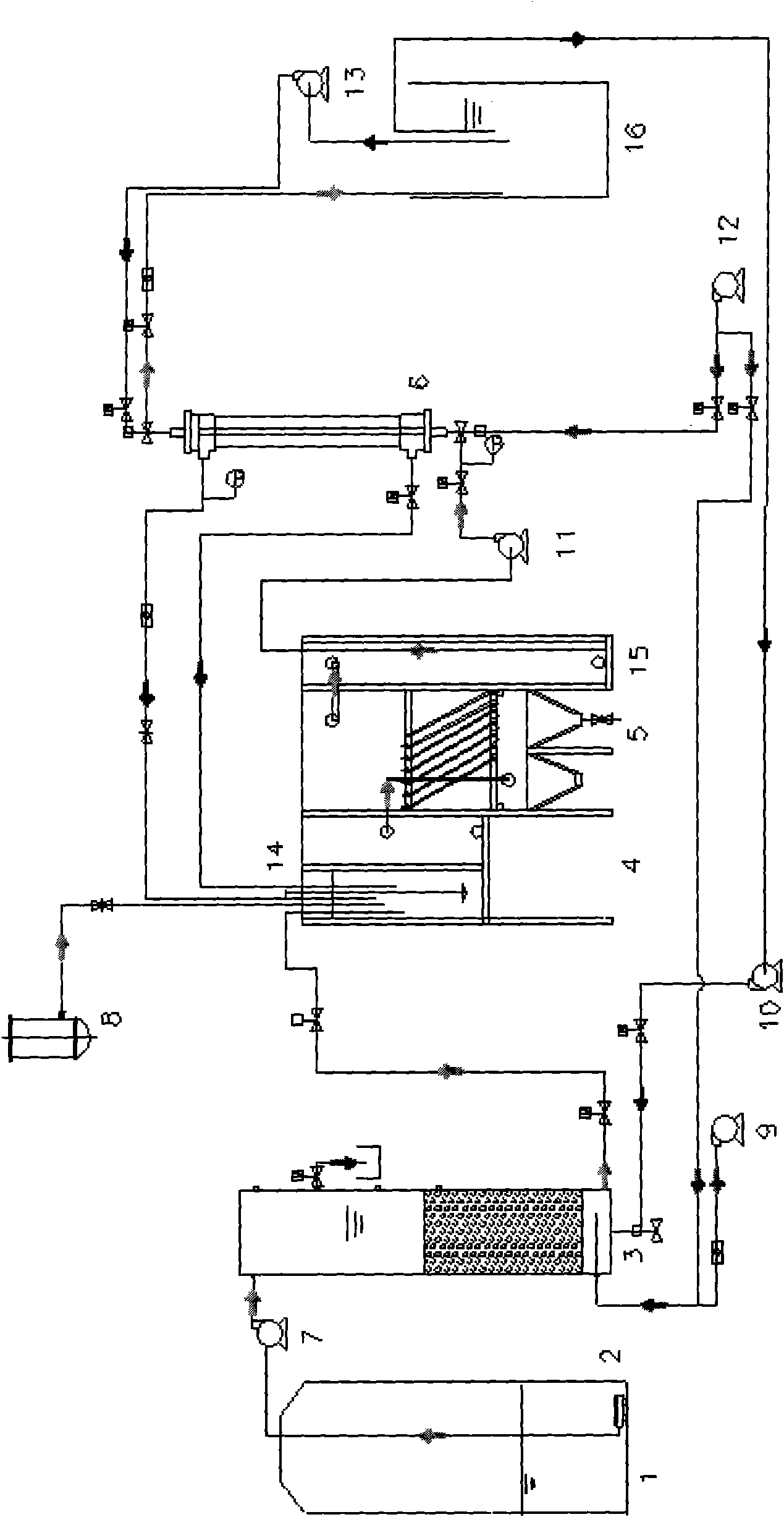

Method used

Image

Examples

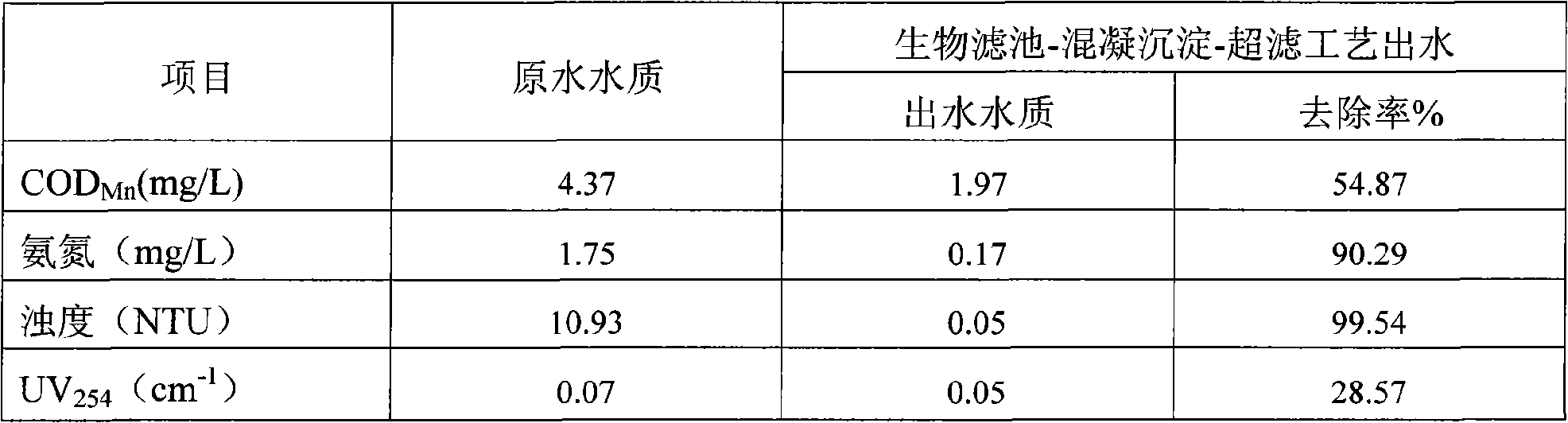

Embodiment 1

[0024] Example 1: The raw water to be treated is lake water. The raw water pump draws water from the raw water pool and enters the biofilter through the disc filter. The biofilter adopts 2-3mm zeolite. The hydraulic retention time in the biofilter is 30min, and the gas-water ratio is 2:1. The effluent enters the coagulation sedimentation tank, and the dosing system adds polyaluminum chloride to the coagulation sedimentation tank at a rate of 6 mg / L. After coagulating for 5 minutes, it enters the inclined plate sedimentation tank, settles in the inclined plate sedimentation tank for 30 minutes, and the supernatant After entering the middle pool, it is sucked and pressurized by the ultrafiltration pump into the ultrafiltration membrane module. The ultrafiltration membrane has a pore size of 0.03 microns and is made of polyvinylidene fluoride external ultrafiltration membrane module. The flux is 20L / m 2 .h, the pressure changes between 0.05 ~ 0.07Mpa. After filtering for 30 min...

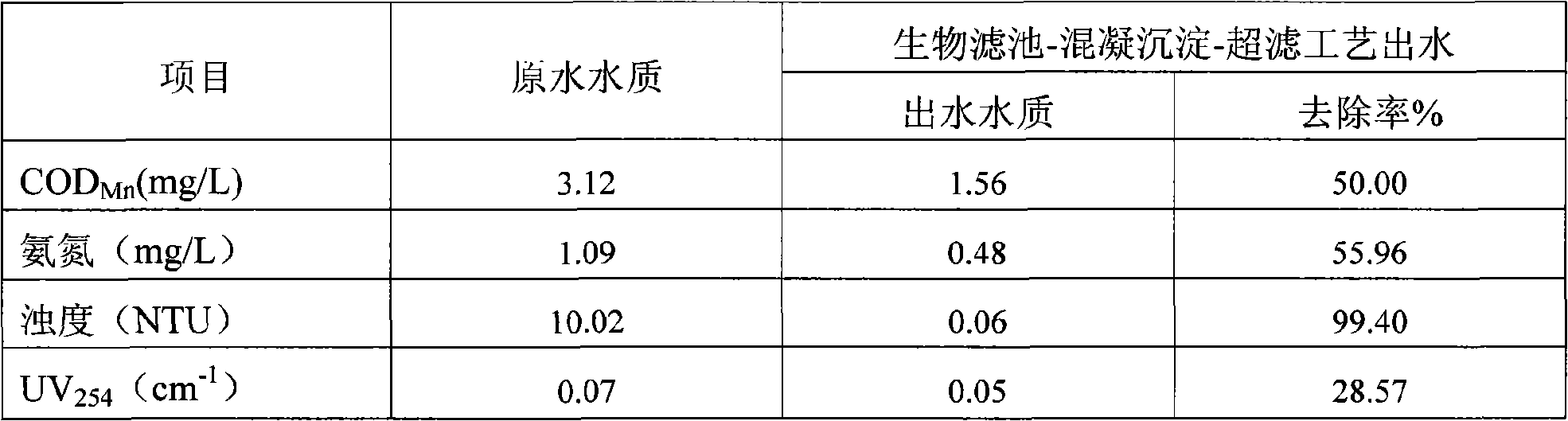

Embodiment 2

[0028] The raw water to be treated is river water. The raw water pump draws water from the raw water pool and enters the biofilter through the disc filter. The biofilter uses 2-3mm zeolite. The hydraulic retention time in the biofilter is 10 minutes, and the gas-water ratio is 0.5:1. The effluent enters the coagulation sedimentation tank, and the dosing system adds aluminum sulfate to the coagulation sedimentation tank at a rate of 4 mg / L. After coagulating for 5 minutes, it enters the inclined plate sedimentation tank, settles in the inclined plate sedimentation tank for 30 minutes, and the supernatant enters the middle The pool is sucked and pressurized by the ultrafiltration pump into the ultrafiltration membrane module. The ultrafiltration membrane has a pore size of 0.1 micron and is made of polyvinylidene fluoride external ultrafiltration membrane module. The flux is 100L / m 2 .h, the pressure changes between 0.12 ~ 0.15Mpa. After filtering for 30 minutes and backwashin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com