Precured resin coated propping agent and preparation method thereof

A resin coating and pre-curing technology, applied in the chemical field, can solve the problems affecting the adhesion of the resin film and the anti-shattering ability of the proppant, and achieve excellent antistatic performance, excellent antistatic and water resistance performance, and improved antistatic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Wherein, if in the pre-cured resin-coated proppant involved, the resin film only includes a resin film containing an antistatic agent, then the above-mentioned preparation method can only include the following steps: 1) heating the aggregate, stirring Add a coupling agent and a resin containing an antistatic agent (the order of adding the two is not limited), so that the resin is coated on the aggregate, and then add a curing agent to cure; 2) When the material is about to agglomerate, add a lubricant to continue Stir until the material is completely dispersed, and continue post-curing; 3) Shake and break the material, cool, and sieve. It is even possible not to add a coupling agent during the preparation.

[0023] Further, in the preparation method of the pre-cured resin-coated proppant of the present invention, in order to improve the bonding strength between the resin and the aggregate and prevent the shelling of the resin and the aggregate, it is preferable to use a...

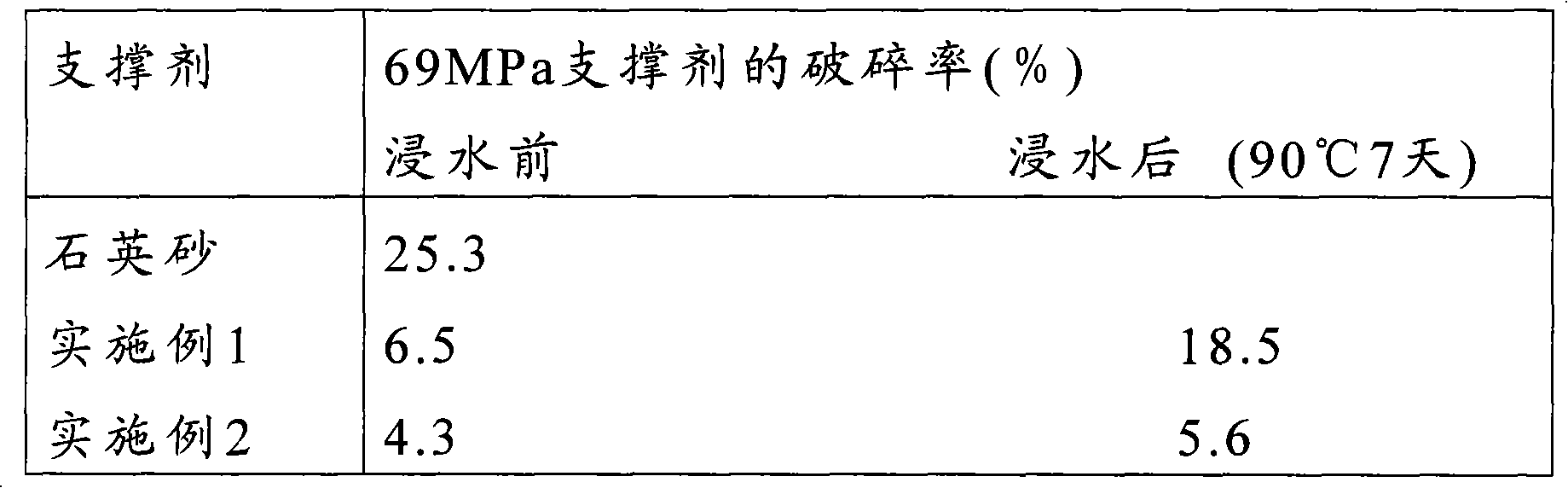

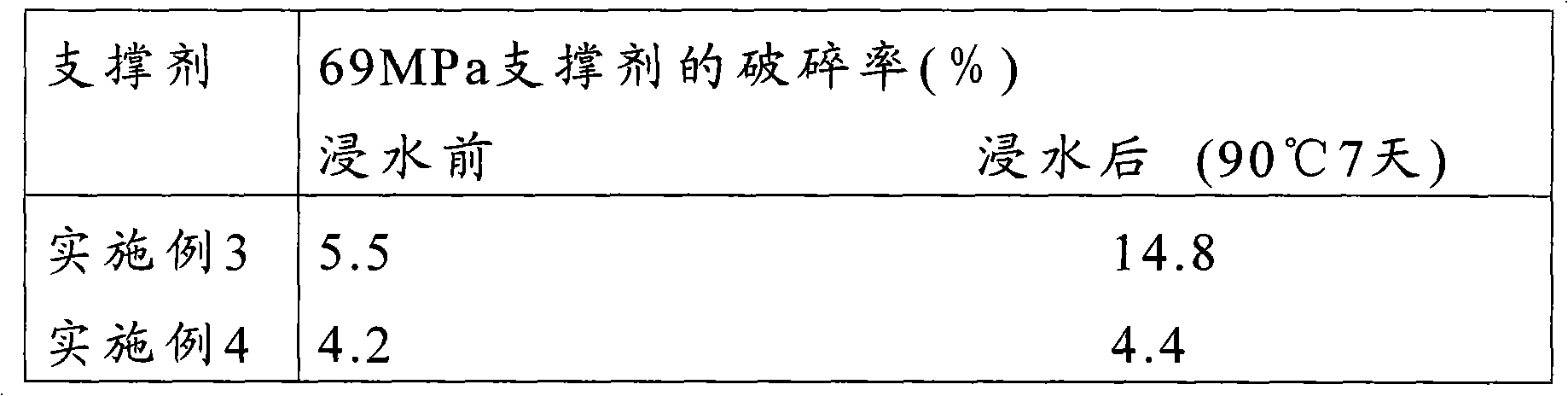

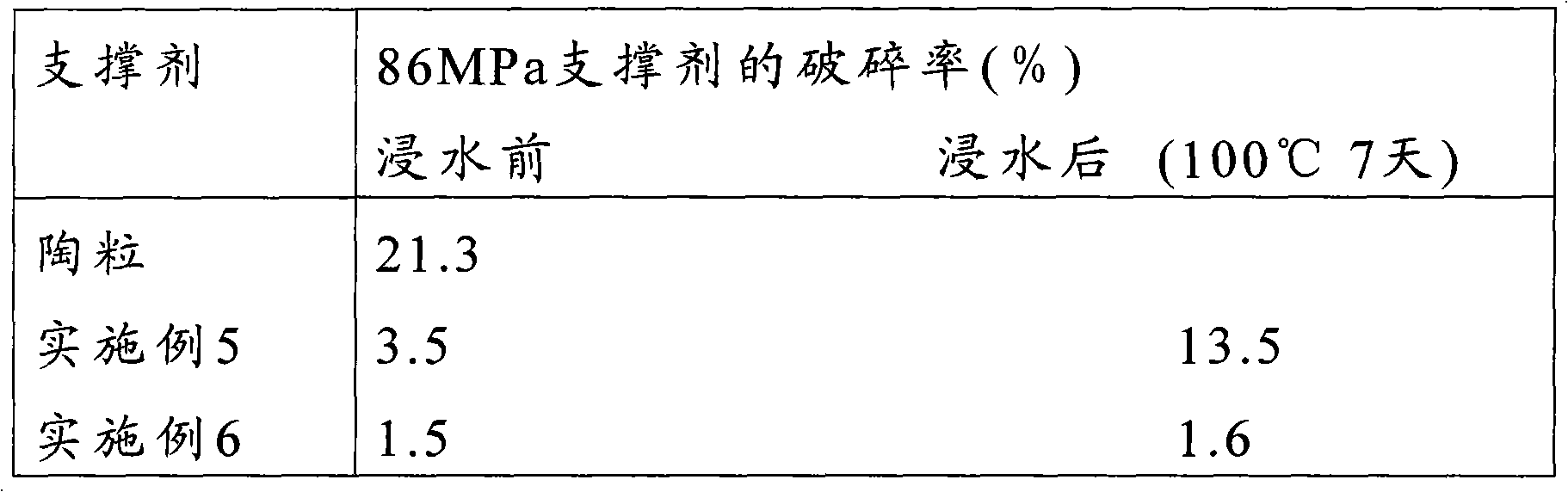

Embodiment 1

[0028] Embodiment 1 (comparative example)

[0029] Heat 5kg of quartz sand (particle size 0.425 / 0.85mm) to 180°C and pour it into a mixer, add 0.5g of γ-aminopropyltriethoxysilane and stir for 30 seconds, add general-purpose phenolic resin 100 Stir for 60 seconds to make it evenly coated on the quartz sand, add 20 grams of hexamethylenetetramine and stir for 120 seconds, then add 150 grams of general-purpose phenolic resin and stir for 100 seconds, add 30 grams of hexamethylenetetramine Stir and solidify. When the material starts to agglomerate, add 15 grams of calcium stearate and continue to stir and solidify for 180 seconds. After cooling, crushing and sieving, the resin-coated quartz sand proppant can be obtained.

Embodiment 2

[0031] Weigh 200 grams of cashew oil modified phenolic resin, heat it to 140 ° C, add 2 grams of Span85, 4 grams of acetylene carbon black, 0.47 grams of cobalt isooctanoate and 0.66 grams of cobalt isooctanoate and stir evenly, sample preparation After measuring its volume resistivity 3×10 3 Ω·cm.

[0032] Heat 5kg of quartz sand (particle size 0.425 / 0.85mm) to 180°C and pour it into a mixer, add 0.5g of γ-aminopropyltriethoxysilane and stir for 30 seconds, add cashew oil modified phenolic Stir 100 grams of resin for 60 seconds to make it evenly coated on the quartz sand, add 20 grams of hexamethylenetetramine and stir for 120 seconds, then add 150 grams of the above-mentioned resin containing antistatic agent and stir for 100 seconds, add hexamethylenetetramine 30 grams of tetramine were stirred and solidified, and when the material began to agglomerate, 15 grams of calcium stearate was added to continue to stir and solidify for 180 seconds, cooled, crushed, and sieved to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com