Preparation method of melt-drip resistant inflaming retarding polyester fiber

A flame-retardant polyester and anti-droplet technology, which is applied in the manufacture of fire-retardant and flame-retardant filaments, fiber processing, and single-component polyester rayon, etc., can solve the problems of unsatisfactory effect, complicated preparation process and increased fiber production cost. and other problems, to achieve significant economic and social benefits, simple production process, and convenient industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

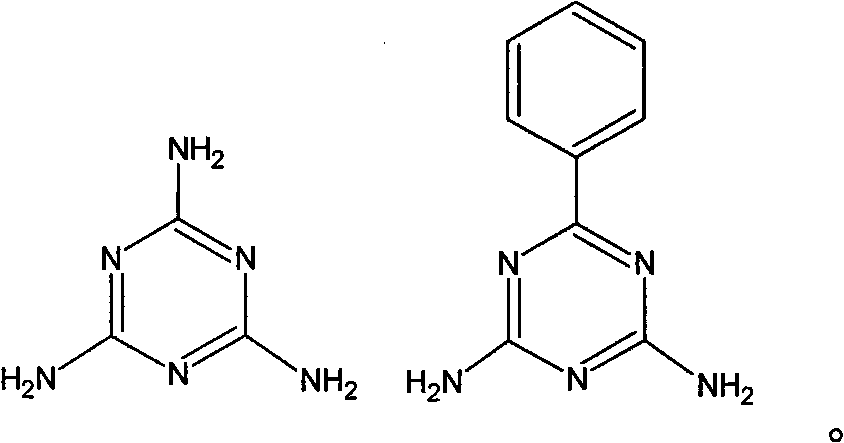

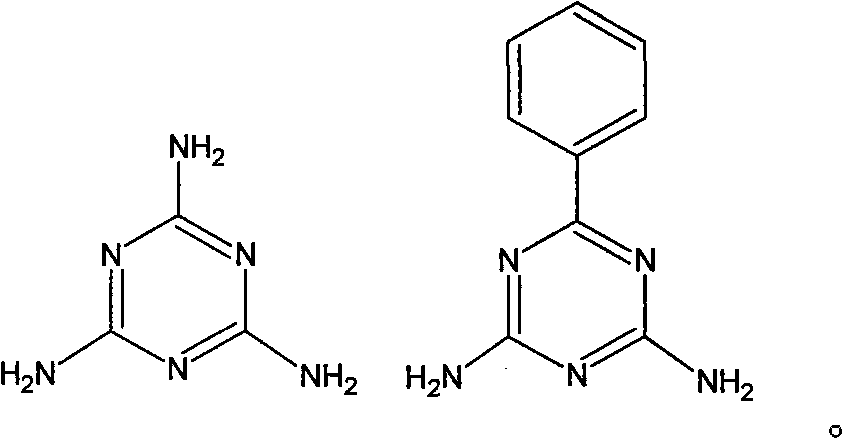

[0030] (1) Mixing: 100g of polyester chips are put into a vacuum oven to dry and taken out, mixed evenly with 2g of benzomelamine in a twin-screw extruder, and cut into anti-droplet flame-retardant polyester chips;

[0031] (2) Melt spinning: put the anti-droplet flame-retardant polyester chip into a vacuum oven to dry, and then refer to the conventional polyester fiber melt-spinning method to melt-spin to obtain the primary anti-droplet flame-retardant polyester Ester fiber;

[0032] (3) fiber alkaline solution treatment: get paraformaldehyde, configure and obtain the formaldehyde solution of 70% concentration by weight, get 6g formaldehyde solution and place in the reaction vessel, adjust the solution pH value to be 8 with triethanolamine, control the solution temperature Constant at 50°C. The reactor can realize the contact mixing of the fiber and the solution through self-vibration, and the primary anti-droplet flame-retardant polyester fiber is placed in the reaction ves...

Embodiment 2

[0039] (1) Mixing: 100g of polyester chips are put into a vacuum oven to dry and taken out, mixed evenly with 10g of benzomelamine in a twin-screw extruder, cut into anti-melting droplet flame retardant polyester chips;

[0040] (2) Melt spinning: put the anti-droplet flame-retardant polyester chip into a vacuum oven to dry, and then refer to the conventional polyester fiber melt-spinning method to melt-spin to obtain the primary anti-droplet flame-retardant polyester Ester fiber;

[0041] (3) fiber alkaline solution treatment: get the formaldehyde solution that the weight percent concentration is 35%, configure and obtain the formaldehyde solution that the weight percent concentration is 20%, get 800g formaldehyde solution and place reaction vessel, adjust solution pH with diethanolamine The value is 9, and the temperature of the solution is controlled to be constant at 35°C. The reactor can realize the contact mixing of the fiber and the solution through self-vibration, and...

Embodiment 3

[0047] (1) Mixing: 100g polyester chips are put into a vacuum oven to dry and taken out, mixed evenly with 30g benzomelamine in a twin-screw extruder, cut into anti-melt drop flame retardant polyester chips;

[0048] (2) Melt spinning: put the anti-droplet flame-retardant polyester chip into a vacuum oven to dry, and then refer to the conventional polyester fiber melt-spinning method to melt-spin to obtain the primary anti-droplet flame-retardant polyester Ester fiber;

[0049] (3) Fiber alkaline solution treatment: get the formaldehyde solution that is 35% by weight concentration, configure the formaldehyde solution that is 10% by weight concentration, get 1500g formaldehyde solution and place in the reaction vessel, adjust the solution with sodium hydroxide The pH value was 9, and the temperature of the solution was kept constant at 40°C. The reactor can realize the contact mixing of the fiber and the solution through self-vibration, and the primary anti-droplet flame-retar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com