Analysis measuring method for brominated flame-retardant in plastic component of deserted household electrical appliance

A technology for brominated flame retardants and plastic parts is applied in the field of analysis and determination of brominated flame retardants in plastic parts of waste household appliances, which can solve the problems of incomplete purification of impurities, poor repeatability and accuracy of analysis results, and large amount of solvent used. problems, to reduce the cost of sample analysis, simplify the sample cleanup process, and improve the effect of solubility limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

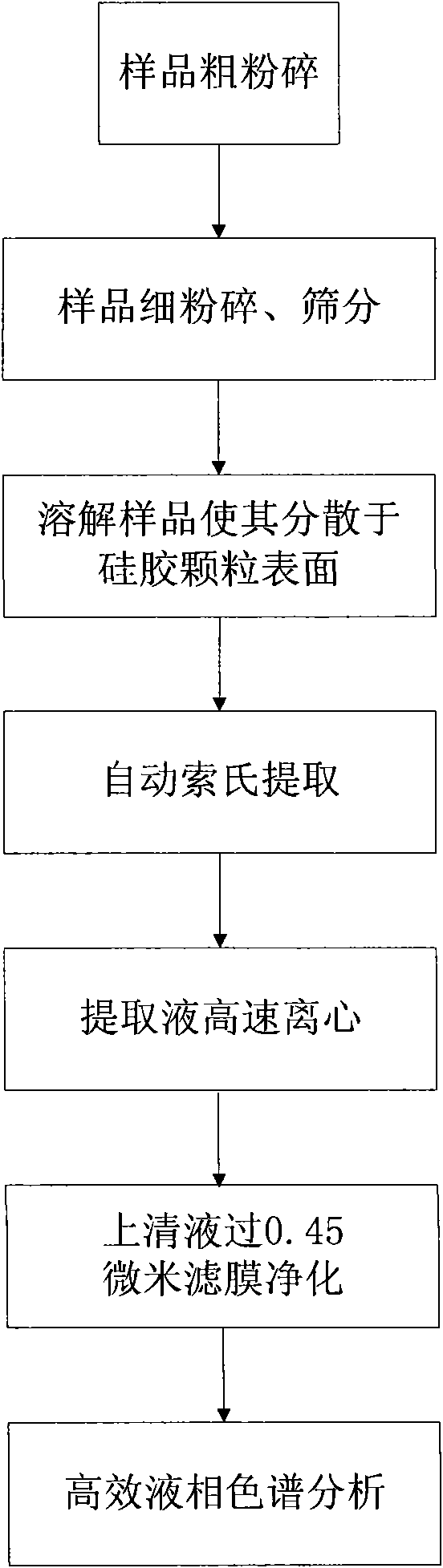

Method used

Image

Examples

Embodiment 1

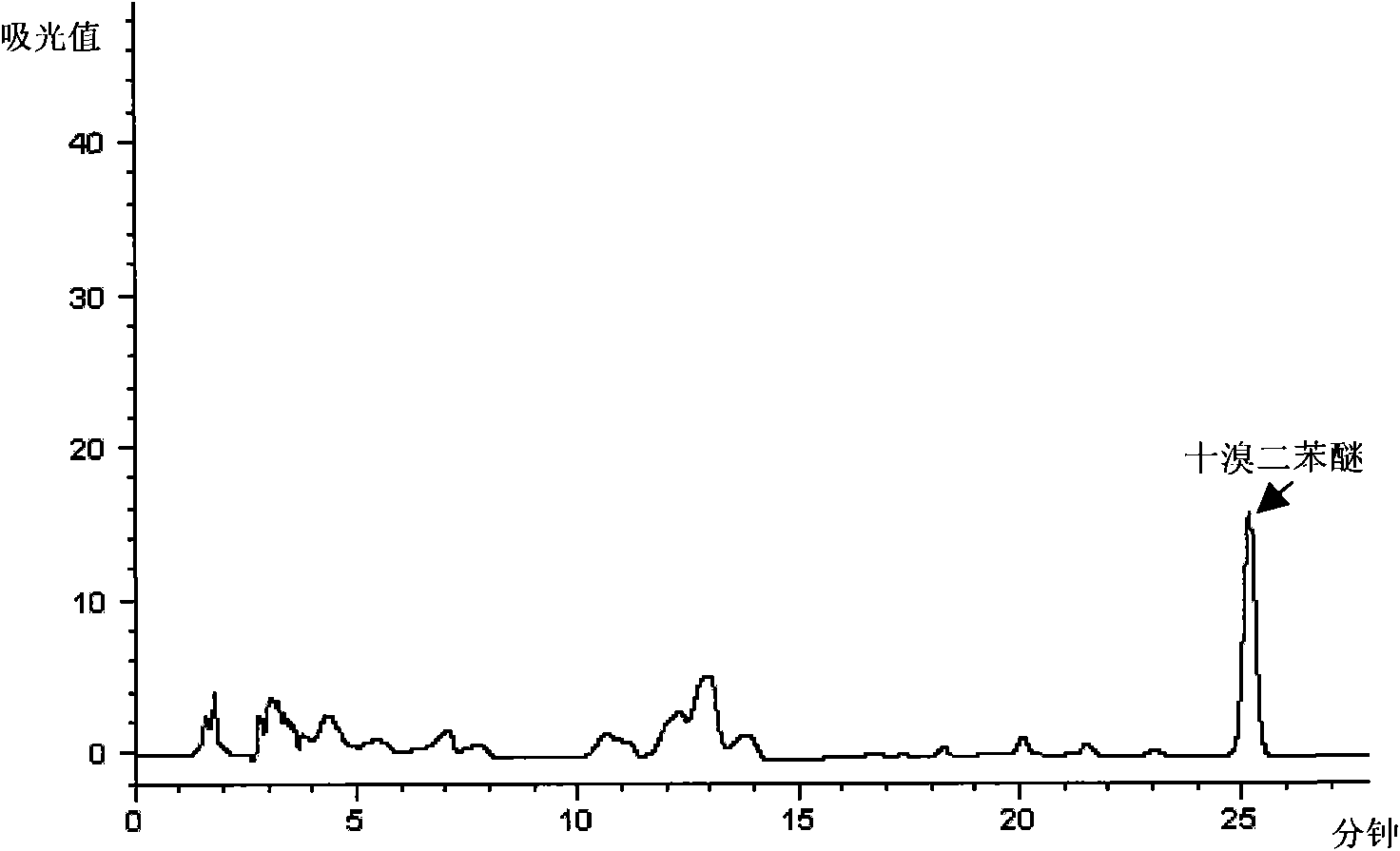

[0026] The invention is used to analyze the casing of a certain domestic brand TV set and the casing of a certain domestic brand water dispenser, and determine the type and content of brominated flame retardants therein.

[0027] The casing of the TV set and the casing of the water dispenser were collected as samples. After the two samples are coarsely crushed into a diameter of 1cm, the coarsely crushed samples are further finely crushed with a hammer mill. By connecting the screening device to the discharge port of the pulverizer, the online connection of fine crushing and screening is realized. Use, carry out online combined screening, collect 18 mesh sieves and sieve.

[0028] Use an electronic balance to weigh 1 g of the TV casing and water dispenser casing samples processed in the previous step and place them in a 50mL glass beaker; use a graduated cylinder to measure 25mL of tetrahydrofuran (purity: chromatographic grade) and mix them with the plastic sample evenly, and...

Embodiment 2

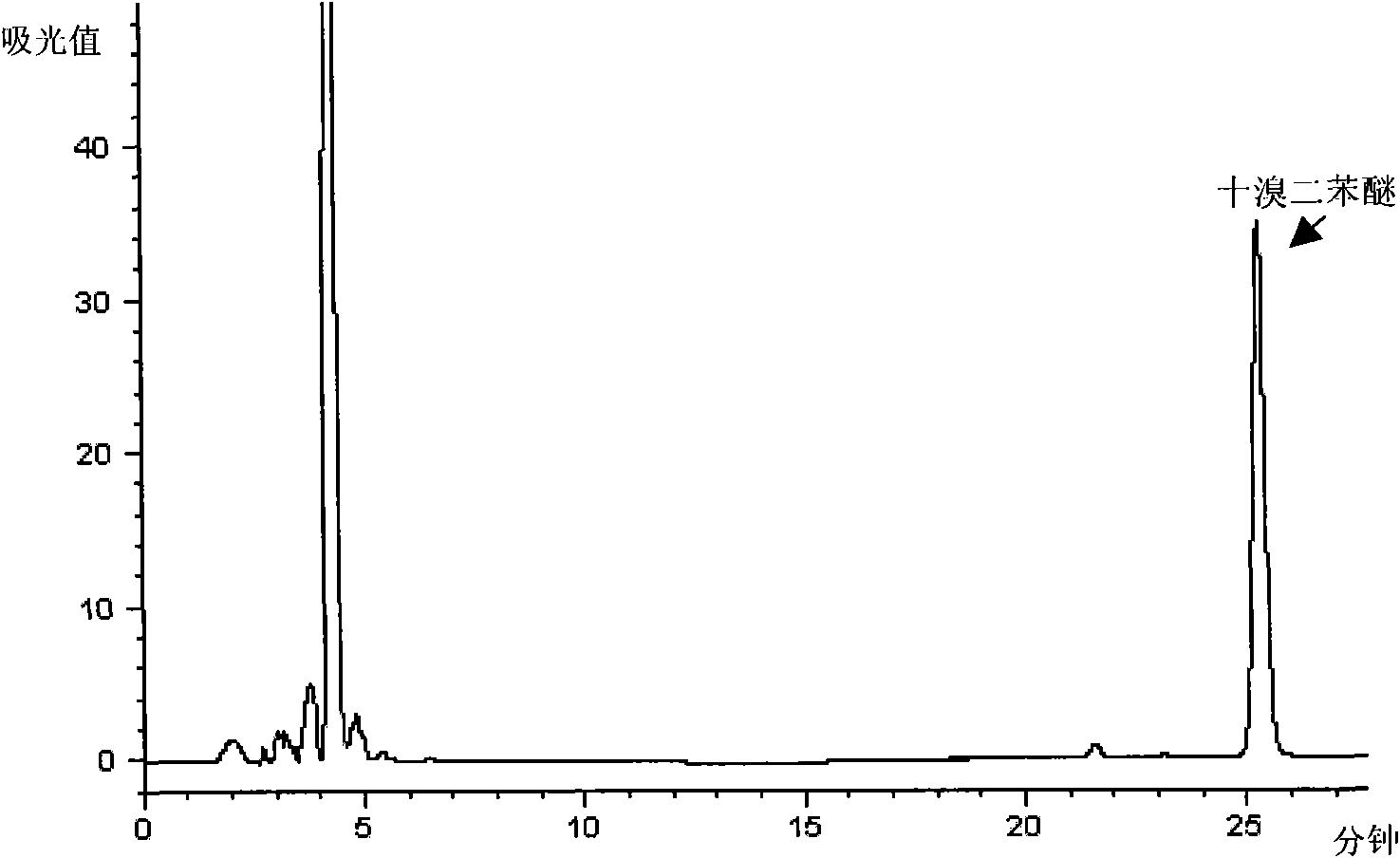

[0032] The present invention is used to analyze a computer case of a certain brand in the United States.

[0033] Take several representative samples of the computer case. Coarsely pulverize the sample into a size of 1 cm in diameter, use a hammer mill to further pulverize the coarsely pulverized sample, and collect and sieve through a 18-mesh sieve through online joint screening. Accurately weigh 2g of the computer case sample processed in the previous step into a 100mL glass beaker; use a graduated cylinder to measure 30mL of dichloromethane (purity: chromatographic grade) and mix it with the plastic sample evenly, stir to dissolve the sample in the solvent; weigh 20g of silica gel particles (60-100 mesh) mixed with the above solution evenly, and continue to stir to make the solution mix more evenly, and at the same time, completely volatilize the solvent in the sample at a temperature of 25°C to obtain a plastic sample that forms a uniformly distributed plastic film on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com