Organic solvent dispersion of conductive polymer/dopant and composition containing the dispersion

A technology of conductive polymers and organic solvents, used in conductive paints, coatings, latex paints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

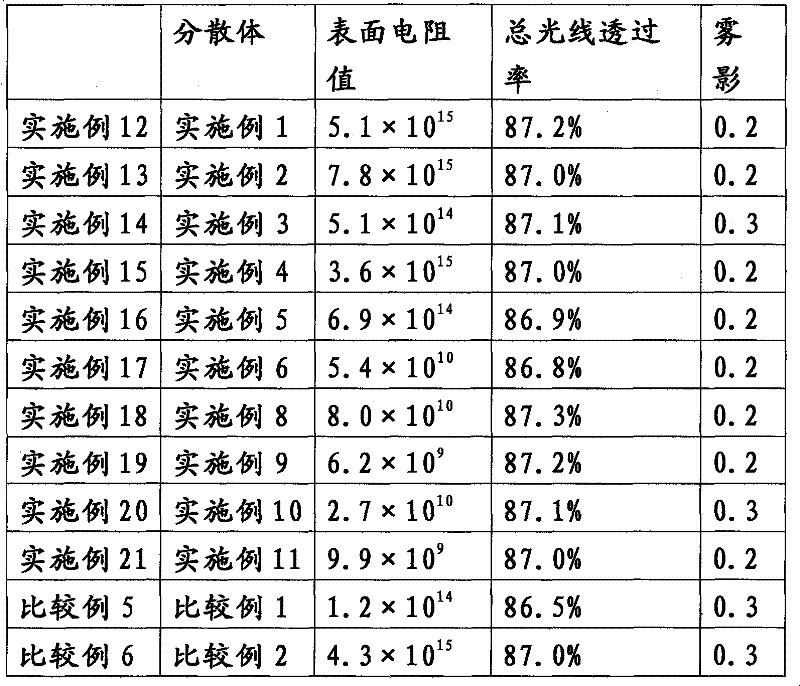

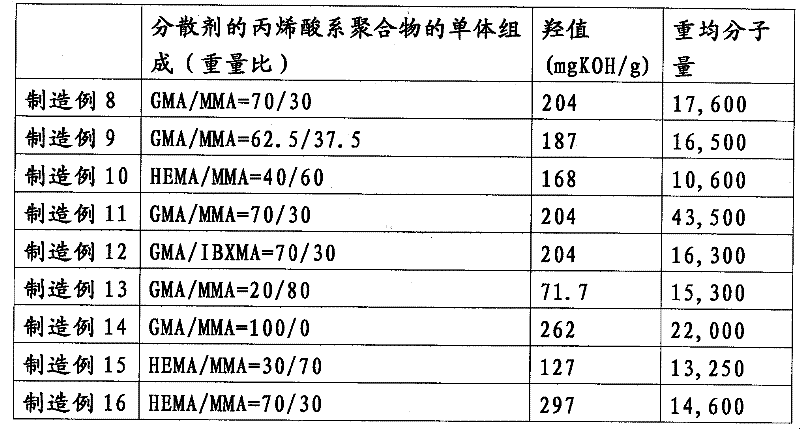

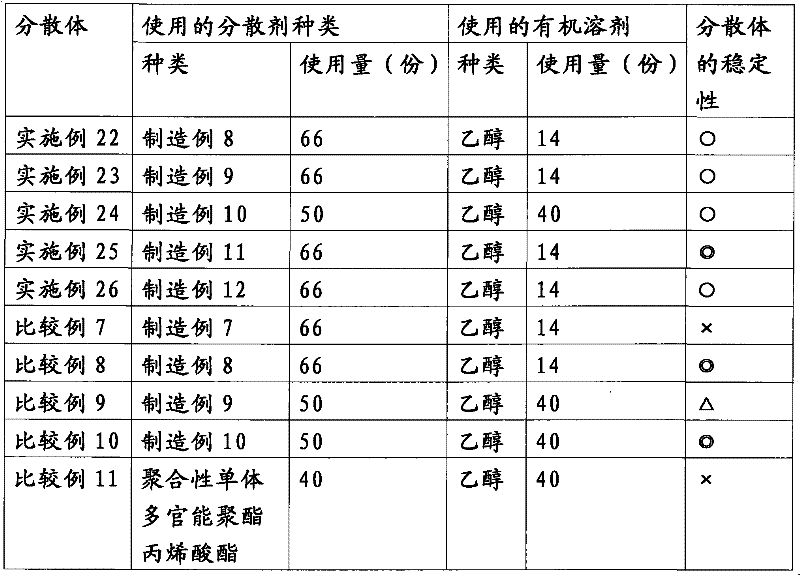

Examples

manufacture example 1

[0128]In a reaction device with stirring device, cooling tube, dropping funnel and nitrogen introduction tube, 200 parts of glycidyl methacrylate (hereinafter referred to as GMA), 50 parts of methoxypolyethylene glycol monomethacrylate , 1.3 parts of dodecyl mercaptan, 1000 parts of butyl acetate and 7.5 parts of 2,2'-azobisisobutyronitrile (hereinafter referred to as AIBN) are loaded, and the temperature in the system is lowered for about 1 hour under nitrogen flow. Raise the temperature to about 85°C and keep it warm for 1 hour. Then, from a dropping funnel preloaded with a mixture of 600 parts of GMA, 150 parts of methoxypolyethylene glycol monomethacrylate, 3.7 parts of dodecanethiol and 22.5 parts of AIBN, under nitrogen flow, It took about 2 hours to make the mixed solution drop into the system, and after maintaining the temperature at the same temperature for 3 hours, add 10 parts of AI BN and keep the temperature for 1 hour. Then, the temperature was raised to 120° C....

manufacture example 2

[0130] In the reaction device with stirring device, cooling tube, dropping funnel and nitrogen introduction pipe, 175 parts of glycidyl methacrylate (hereinafter referred to as GMA), 62.5 parts of methyl methacrylate (hereinafter referred to as MMA), 12.5 parts of methoxypolyethylene glycol monomethacrylate, 1.3 parts of dodecanethiol, 1000 parts of butyl acetate and 7.5 parts of 2,2'-azobisisobutyronitrile (hereinafter referred to as AIBN) Thereafter, under nitrogen flow, the temperature in the system was raised to about 85° C. over about 1 hour, and the temperature was maintained for 1 hour. Then, from the dropping funnel pre-loaded with a mixture of 525 parts of GMA, 187.5 parts of MMA, 37.5 parts of methoxypolyethylene glycol monomethacrylate, 3.7 parts of dodecanethiol and 22.5 parts of AIBN , under nitrogen flow, it took about 2 hours to make the mixed liquid drop into the system, and after keeping the same temperature for 3 hours, add 10 parts of AIBN and keep the tempe...

manufacture example 3

[0132] In the reaction device with stirring device, cooling tube, dropping funnel and nitrogen introduction tube, 162.5 parts of glycidyl methacrylate (hereinafter referred to as GMA), 87.5 parts of methoxy polyethylene glycol monomethacrylate , 1.3 parts of dodecyl mercaptan, 1000 parts of butyl acetate and 7.5 parts of 2,2'-azobisisobutyronitrile (hereinafter referred to as AIBN) are loaded, and the temperature in the system is lowered for about 1 hour under nitrogen flow. Raise the temperature to about 85°C and keep it warm for 1 hour. Then, from the dropping funnel pre-loaded with a mixture of 487.5 parts of GMA, 262.5 parts of methoxypolyethylene glycol monomethacrylate, 3.7 parts of dodecanethiol and 22.5 parts of AIBN, under nitrogen flow It took about 2 hours to make the mixed solution drop into the system, and after maintaining the same temperature for 3 hours, add 10 parts of AIBN and keep the temperature for 1 hour. Then, the temperature was raised to 120° C., and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com