Expanded silicone fireproof seal gum and method of preparing the same

A fireproof sealant, foaming technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve problems such as insufficient foaming performance, achieve low corrosiveness, good sealing effect, and good flame retardant and fireproof performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

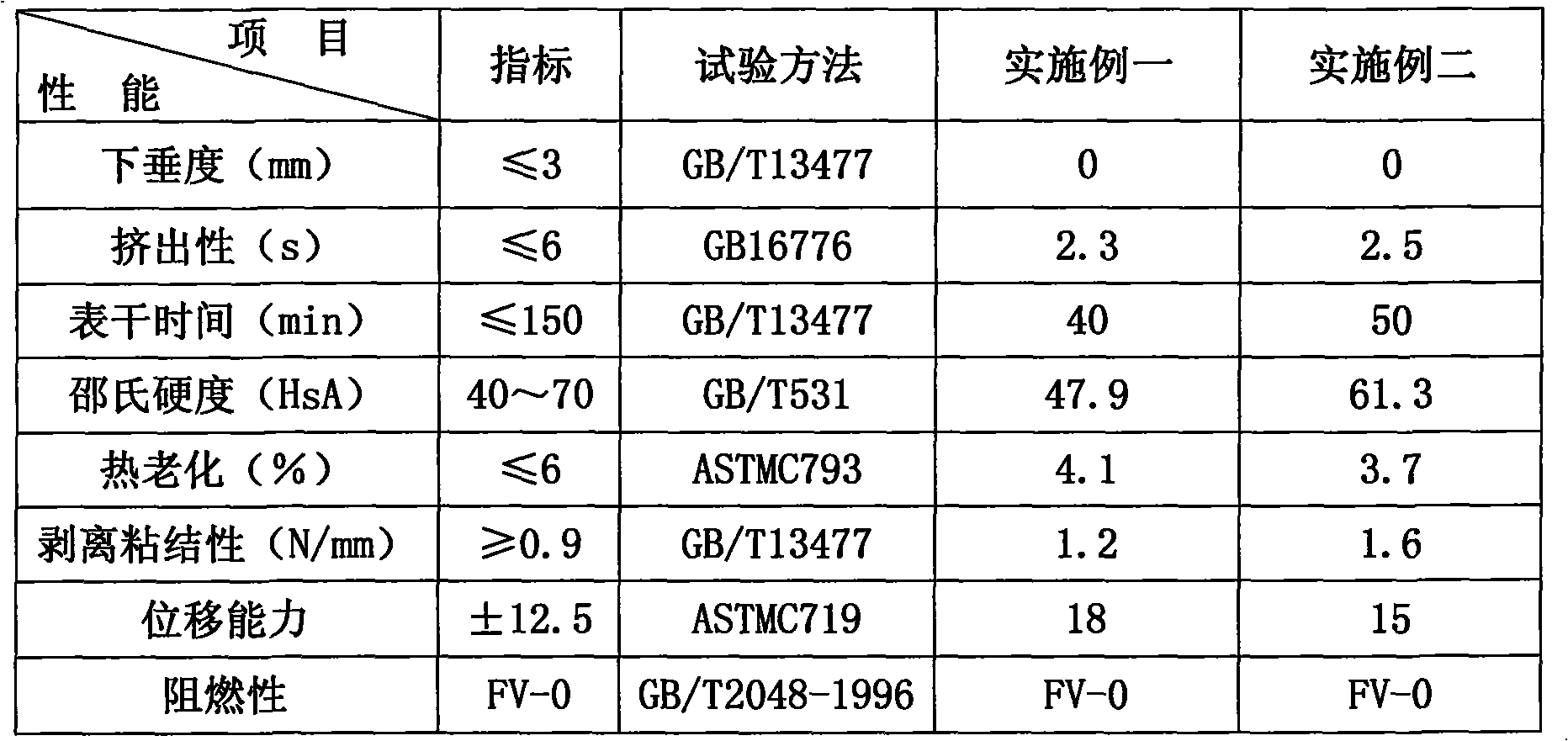

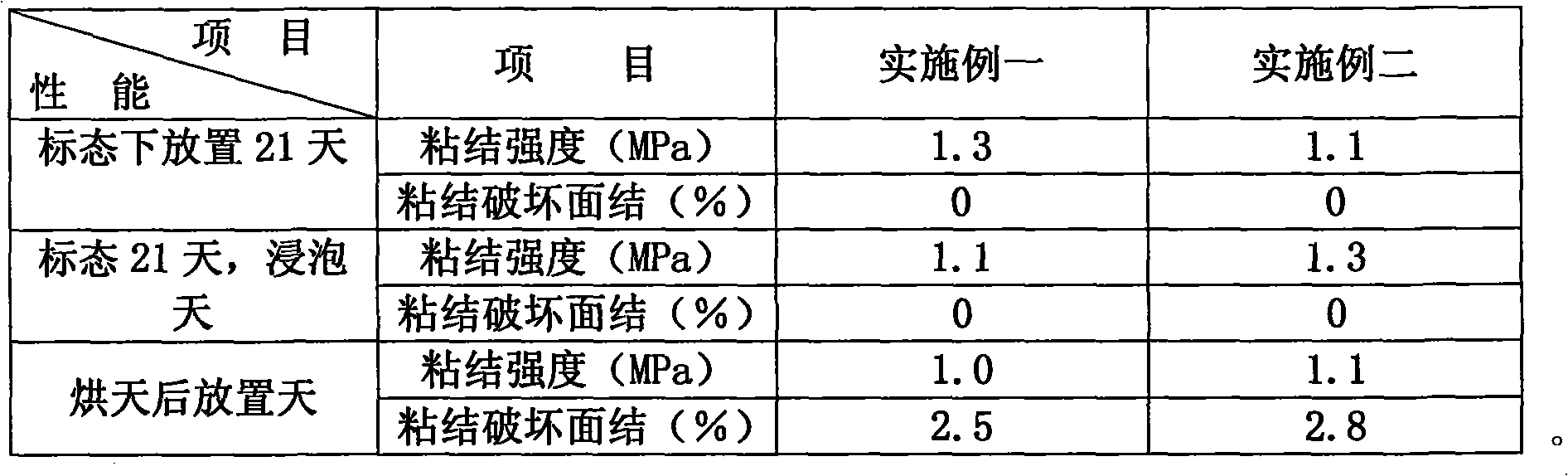

Embodiment 1

[0029] Add 150kg of α, ω-dihydroxypolydimethylsiloxane, 80kg of calcium carbonate and 60kg of zinc borate flame retardant into the multifunctional dispersing mixer in batches and stir, and heat while stirring until the temperature reaches 65°C, then stop heating. The vacuum degree is -0.06MPa, and the dehydration and blending are carried out for 3 hours. Then 8kg of γ-aminopropyltriethoxysilane, 6kg of polyethylene wax, 5kg of methyltrimethoxysilane, 6kg of isopropyl titanate, 1kg of dibutyltin diacetate and 4.5kg of foamable ammonium polyphosphate were divided into Add batches to the multifunctional dispersing mixer, mix with the above α, ω-dihydroxy polydimethylsiloxane mixture, control the temperature at 65°C, stir thoroughly for 5 hours, cool the material, and obtain a foamable silicone fireproof sealant .

Embodiment 2

[0031] Add 200kg of α, ω-dihydroxypolydiethylsiloxane, 100kg of talc powder and 55kg of aluminum hydroxide flame retardant into the multifunctional dispersing mixer in batches and stir, and heat while stirring until the temperature reaches 70°C, stop heating . The vacuum degree is -0.06MPa, and the dehydration and blending are carried out for 2.5 hours. Then 7.5kg of γ-(2,3 glycidoxy)propyltrimethoxysilane, 5kg of silicon dioxide, 10kg of phenyltrimethoxysilane, 8kg of butyl titanate, 1kg of dibutyltin dilaurate and foaming Type 6 kg of monoammonium phosphate is added in batches to the multi-functional dispersing mixer, mixed with the above-mentioned α, ω-dihydroxy polydiethylsiloxane mixture, the temperature is controlled at 70 ° C, fully stirred for 6 hours, and the material is cooled to obtain foaming Type silicone fire sealant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com