Composition containing potassium butyrate, preparation method and application thereof in feed additives

A technology of potassium butyrate and composition, applied in the field of compositions containing potassium butyrate, can solve the problems of hindering the production and application of potassium butyrate, unfavorable storage and use, agglomeration, etc. Storage and use, the effect of preventing caking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

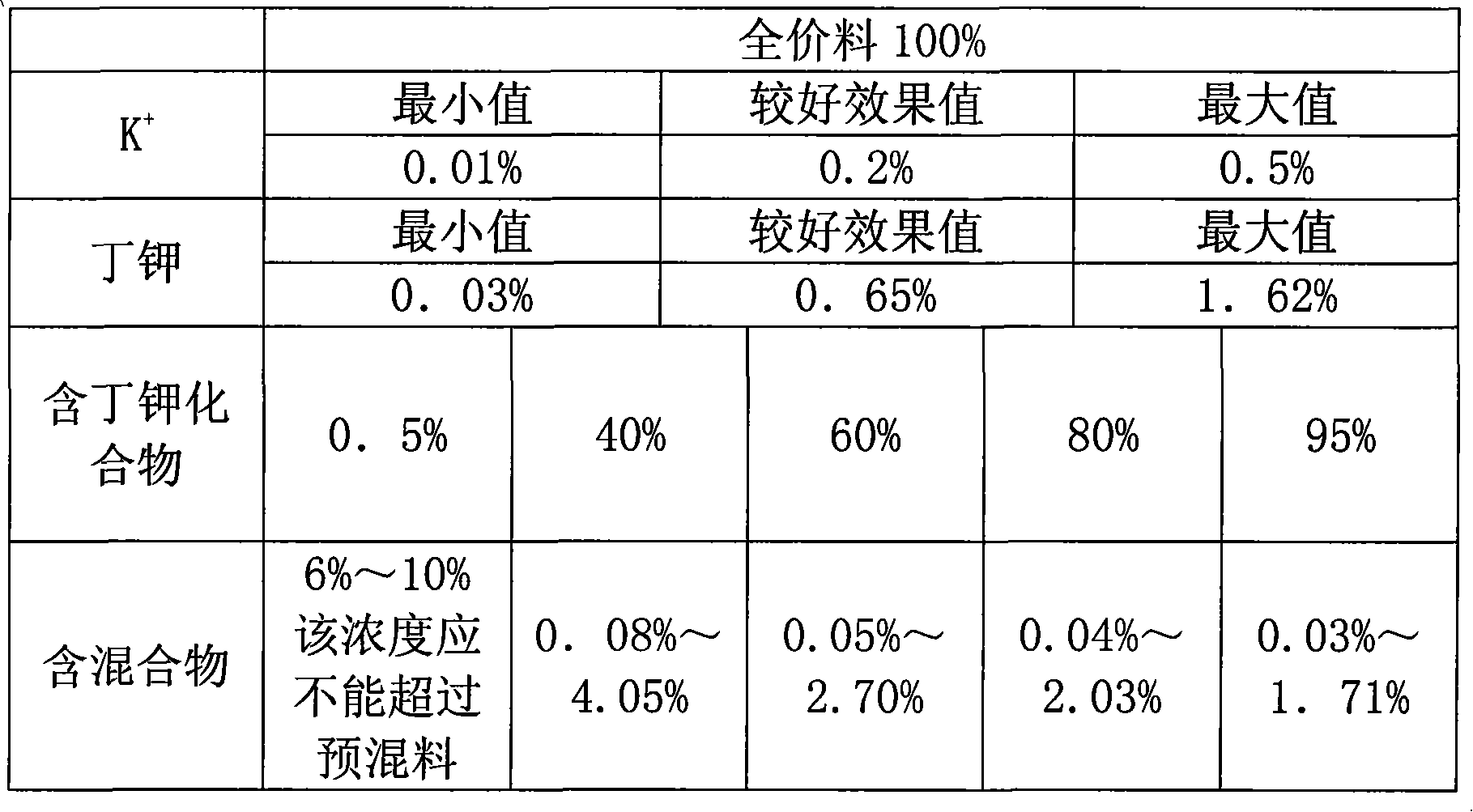

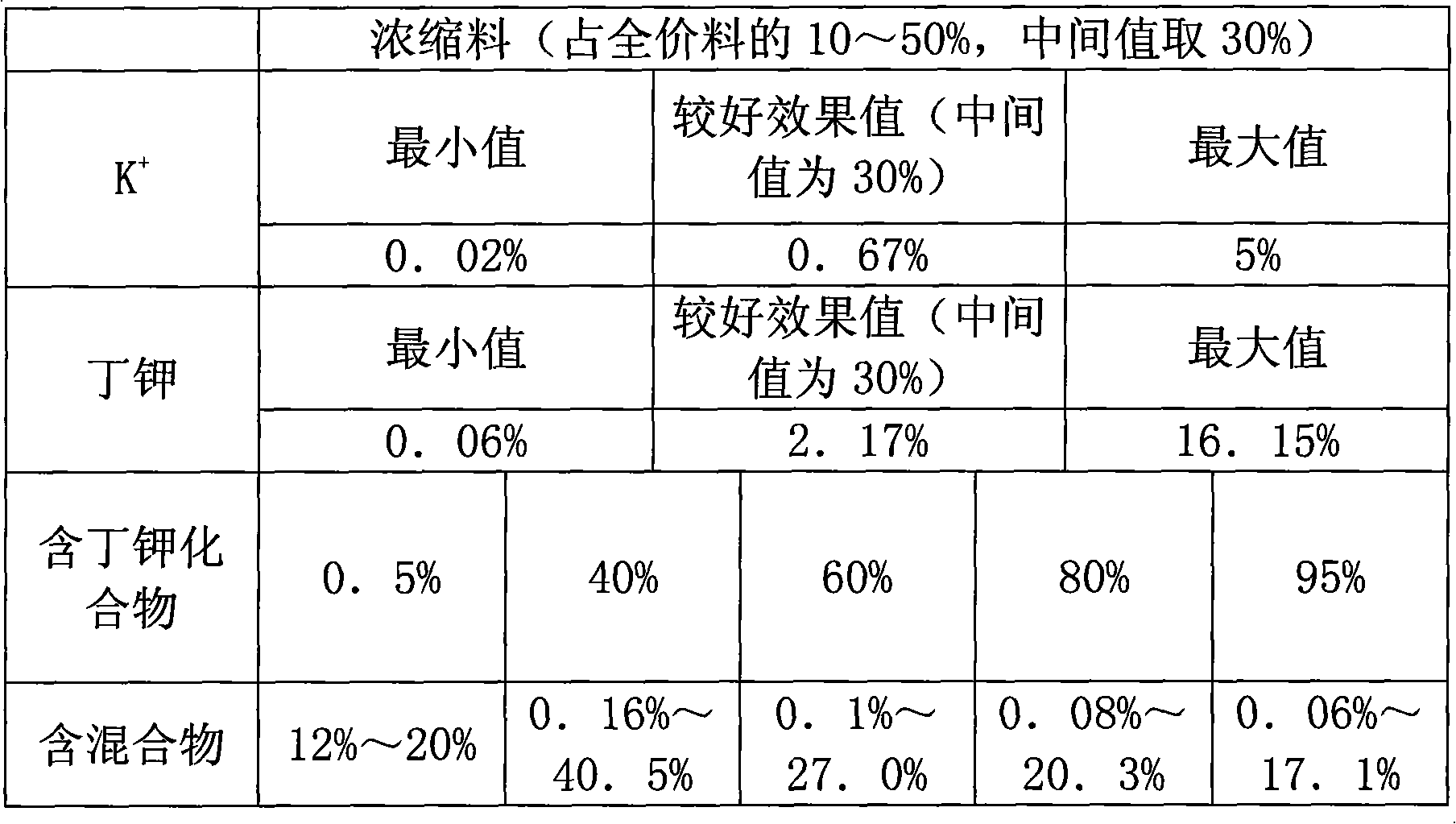

[0028] A composition containing potassium butyrate disclosed by the present invention is composed of the following substances in percentage by weight:

[0029] Potassium butyrate 0.5-95%, dispersant 5-99.5%.

[0030] Among them, silicon dioxide can be specifically used as the dispersant.

[0031] During production and preparation of the composition containing potassium butyrate of the present invention, potassium butyrate is first prepared, comprising the following steps:

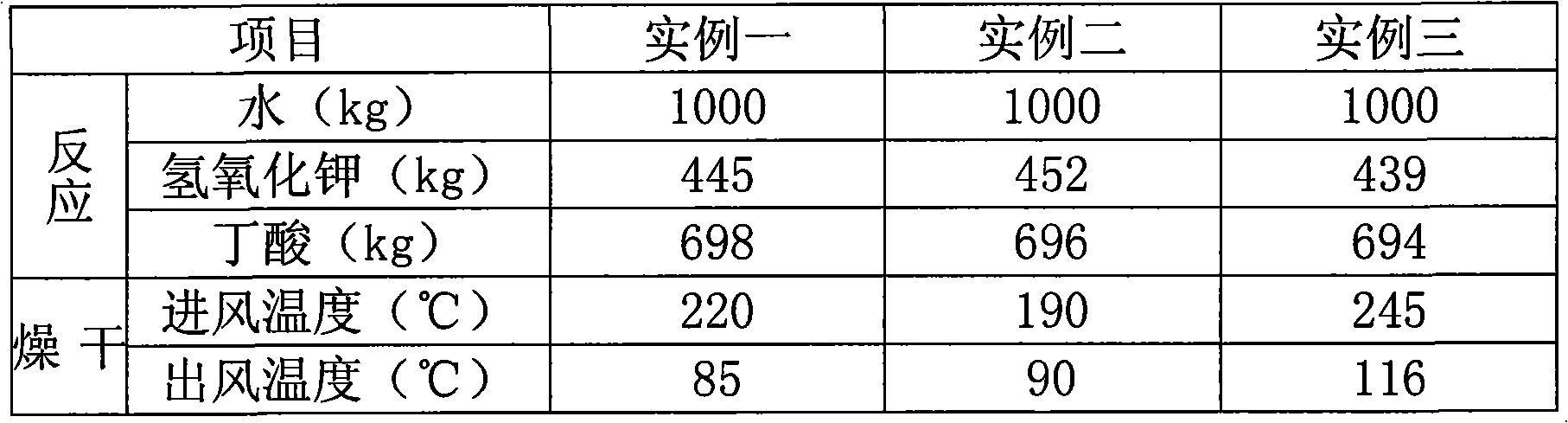

[0032] (1) Acid-base reaction: add 1000 parts by weight of water into the reaction tank, add 435-455 parts by weight of potassium hydroxide under stirring, stir well until dissolved, then add 694-698 parts by weight of butyric acid into the reaction tank , the control temperature is not higher than 105°C, the reaction is completed, and the reaction solution is cooled to a temperature of 25°C to 80°C; see Table 1 for three examples; wherein, the weight parts of each substance can be increased or decreased i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com