Anaerobic built-in zero-valent iron reactor

An anaerobic reactor and zero-valent iron technology, applied in the field of water treatment, can solve problems such as long start-up time, treatment failure, and slow sludge granulation, and achieve the effect of good working performance, small design and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

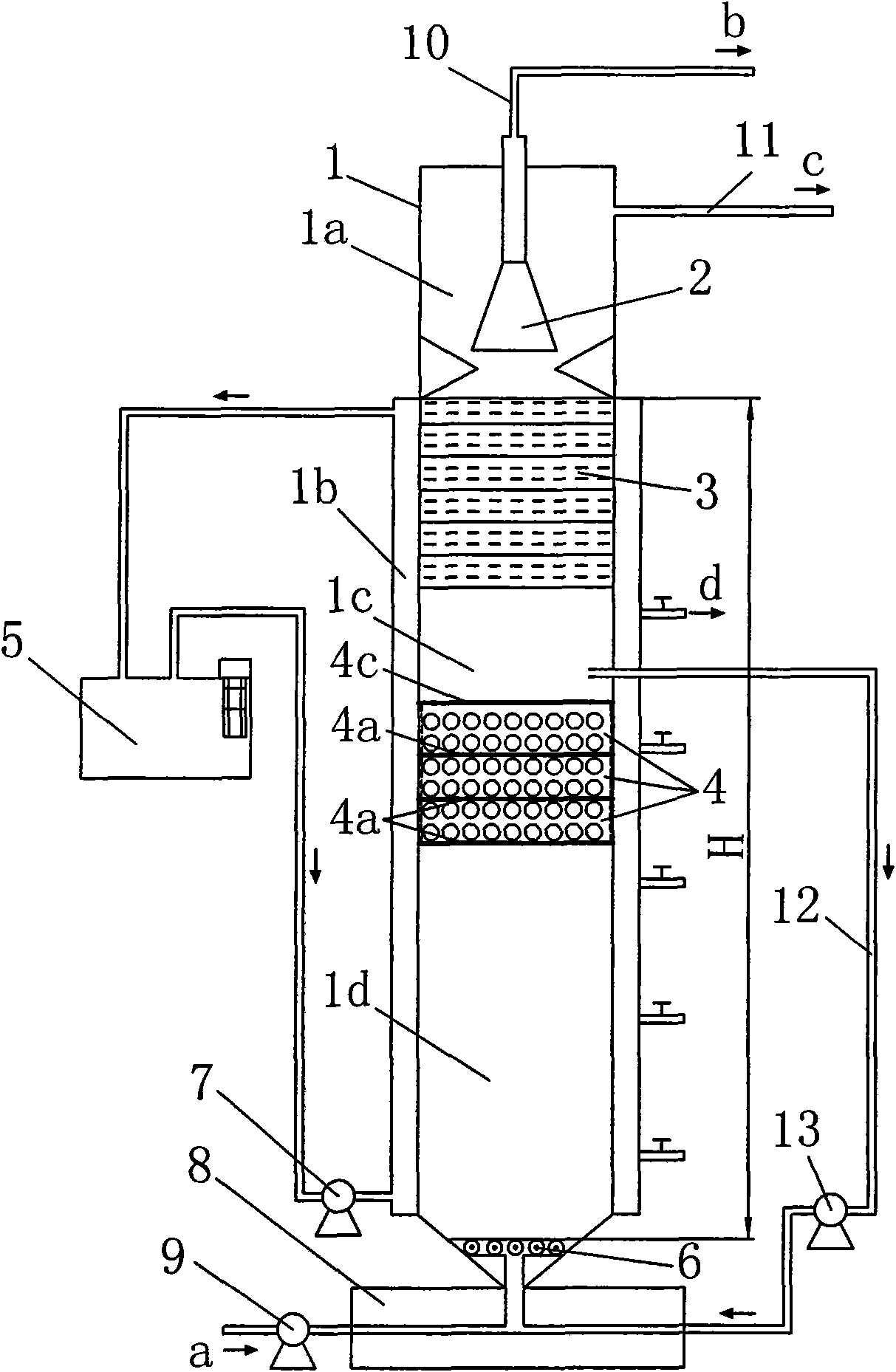

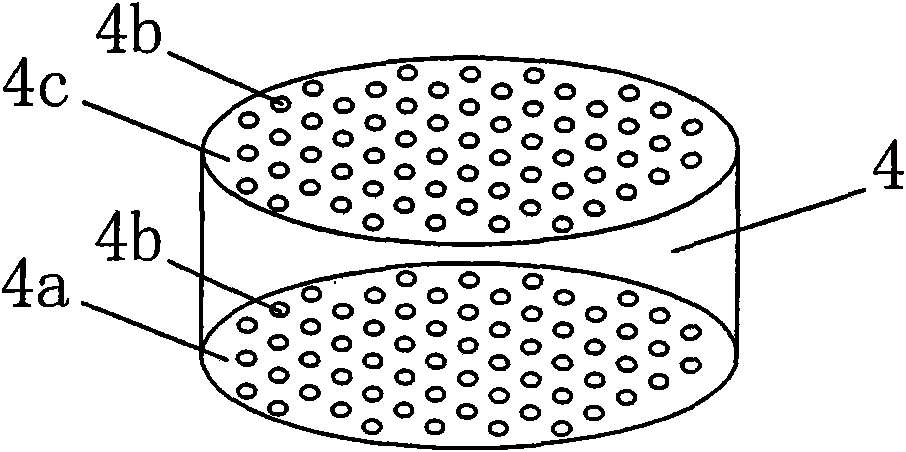

[0021] figure 1 A schematic structural diagram of an anaerobic built-in zero-valent iron reactor is shown. The device mainly includes a cylindrical anaerobic reactor 1. In the anaerobic reactor 1, a water distributor 6, three zero-valent iron filling layers 4, a biological filter layer 3 and a The three-phase separator 2 divides the inner cavity of the anaerobic reactor 1 into a gas-liquid solid separation zone 1a located above the biological filter material layer 3, a suspension zone located between the biological filter material layer 3 and the zero-valent iron filling layer 4 A sludge zone 1c and a sludge expansion zone 1d between the zero-valent iron filling layer 4 and the water distributor 6 . The shell of the anaerobic reactor 1 is made of plexiglass or FRP, with an inner diameter of 90 cm, a height of 120 cm, and an effective volume of 6.36 L. The height of the biological filter material layer 3 and the three-phase separator 2 is 10% of the effective height of the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com