Process for preparing and refining galactomannan-oligosaccharide by microwave combined enzyme method

A technology of galactomannan oligosaccharides and galactomannan, which is applied in the field of microwave combined enzymatic preparation and refined galactomannan oligosaccharides, can solve the problems of large influence on separation effect, high separation cost, and low separation efficiency , to achieve high preparation efficiency, increase reaction efficiency, and reduce the amount of enzyme used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

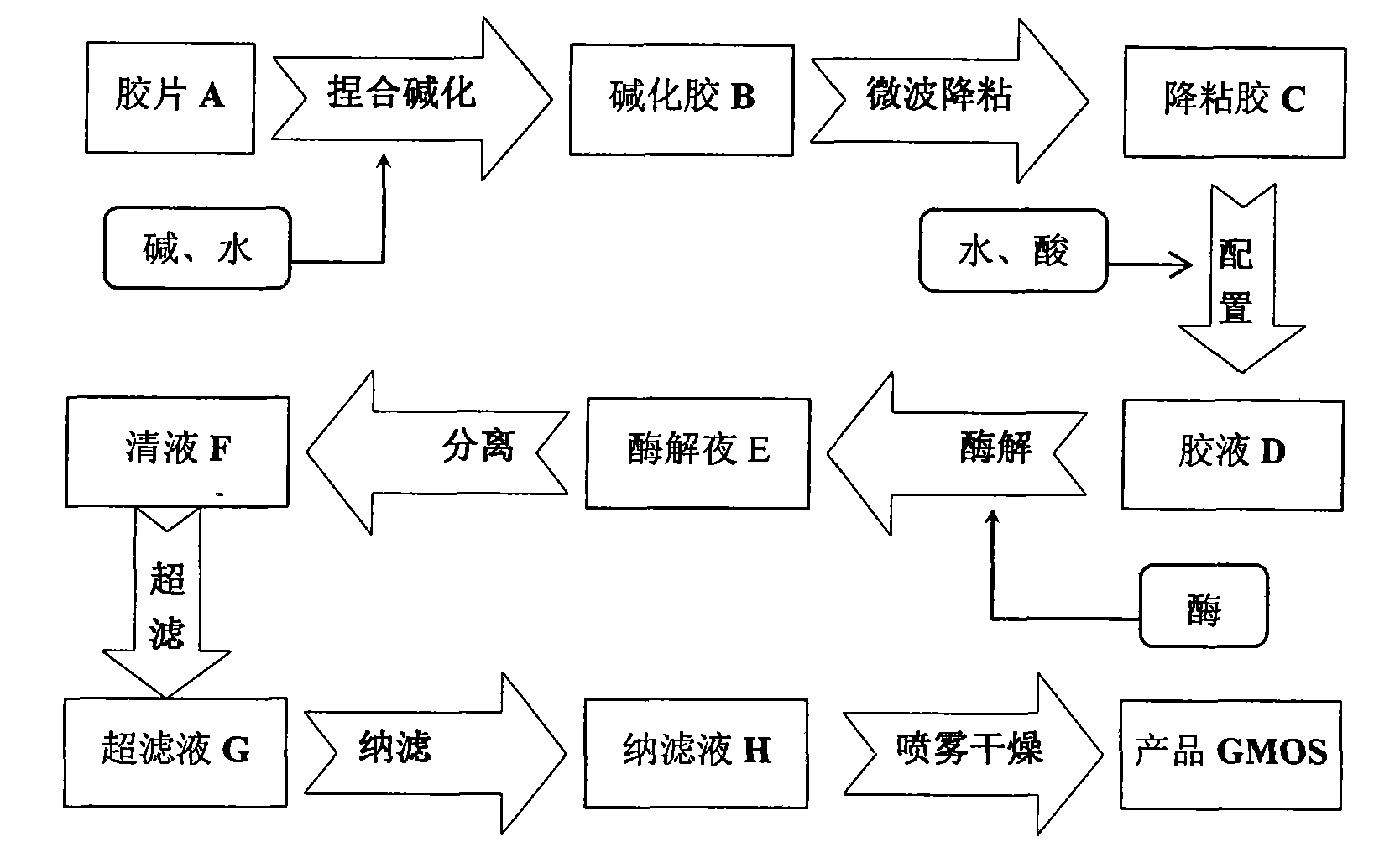

[0034] according to figure 1 In the process flow shown, add 10kg of galactomannan gum endosperm slices into the kneading and stirring device, add 0.5kg of sodium hydroxide, 9kg of water, control the temperature at 55°C, and knead and stir for 45 minutes to completely break the film and absorb water. Swell, get alkalized glue.

[0035] Put the alkalized glue in a cabinet-type microwave equipment, adjust the microwave power to 5.0 kilowatts, treat for 40 minutes, and use intermittent turning to prevent the material from coking, and obtain a reduced-viscosity glue.

[0036] After microwave treatment, put the viscosity-reducing glue in a 100L reaction tank, add water and stir, and make a glue solution with a glue concentration of 14.0wt%, adjust the pH to 8.5 with citric acid, and add the enzyme amount according to 5U / g raw film, Add 25.0 g of alkaline β-mannanase with an enzyme activity of 2000 U / g, control the temperature at 55° C., and perform enzymatic hydrolysis for 4.0 hour...

Embodiment 2

[0041] Put 10kg of locust bean galactomannan gum endosperm slices into the kneading and stirring device, add 0.6kg of potassium hydroxide, 8kg of water, control the temperature at 50°C, and knead and stir for 35 minutes to completely break the film and swell with water absorption to obtain alkalized gum .

[0042] Put the alkalized glue in a cabinet-type microwave equipment, adjust the microwave power to 4.0 kilowatts, treat for 40 minutes, and use intermittent turning to keep the material from coking, and obtain a reduced-viscosity glue.

[0043] After microwave treatment, put the viscosity-reducing glue into a 200L reaction tank, add 160L of water, and stir to form a glue solution with a glue concentration of about 5.9wt%. The amount of enzyme added, 25ml of liquid neutral β-mannanase with an enzyme activity of 200U / ml was added, the temperature was controlled at 65°C, and the enzymolysis was carried out for 6.0 hours to obtain an enzymolysis solution.

[0044] The enzymati...

Embodiment 3

[0047] Put 10kg of guar galactomannan gum endosperm slices into the kneading and stirring device, add 0.8kg of potassium hydroxide, 10kg of water, control the temperature at 65°C, knead and stir for 25 minutes, so that the film is completely broken, and the ingredients absorb water and swell to obtain alkalization glue.

[0048] Put the alkalized guar gum in a belt-type microwave equipment, the total microwave input power is 10 kilowatts, adjust the speed so that the microwave treatment time reaches 15 minutes, and monitor the temperature so that the temperature of the material does not exceed 100 ° C to obtain a reduced viscosity .

[0049] After microwave treatment, put the material into a 150L reaction tank, add 90L of water, stir, and make a glue solution with a glue concentration of about 9.0%, adjust the pH to 8.0 with hydrochloric acid, and add the enzyme amount according to 2.5U / g of raw materials, Add 12.5 g of alkaline β-mannanase with an enzyme activity of 2000 U / g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com